Turning is a cutting method that uses the rotation of the workpiece relative to the tool on a lathe to perform cutting operations. CNC turning allows the workpiece rather than the tool to provide most of the cutting energy. Turning is the most fundamental and commonly used cutting method, and it occupies an extremely important position in production. Turning is suitable for processing rotary surfaces. Most workpieces with rotary surfaces can be processed using turning methods, such as inner and outer cylindrical surfaces, inner and outer conical surfaces, end faces, grooves, threads, and rotary forming surfaces. The main tool used is the turning tool.

The technology of numerical control lathe machining is similar to that of ordinary lathe machining, but because numerical control lathe machining is done in a single setup, completing all turning operations automatically and continuously, attention should be paid to the following aspects.

For efficient metal cutting, the material being machined, cutting tools, and cutting conditions are the three main factors. These determine the processing time, tool life, and processing quality. The most economical and effective processing method is to choose the cutting conditions reasonably. The three elements of cutting conditions for CNC turning: cutting speed, feed rate, and cutting depth directly cause damage to the tool. With the increase of cutting speed, the temperature of the cutting edge will rise, resulting in mechanical, chemical, and thermal wear. When the cutting speed is increased by 20%, the tool life will be reduced by half. The relationship between feed conditions and the wear behind the tool is generated in a very small range. However, when the feed rate is high, the cutting temperature rises, and the wear behind the tool is great. It has a smaller impact on the tool than cutting speed. Although the impact of cutting depth on the tool is not as great as that of cutting speed and feed rate, when cutting at a small depth, a hardening layer is produced in the material being cut, which will also affect the tool life.

Users should select the cutting speed that is suitable for the material being processed, the hardness, cutting state, material type, feed rate, and cutting depth. The selection of the most suitable processing conditions is based on these factors. Regular and stable wear that reaches the life of the tool is the ideal condition. However, in actual operations, the selection of tool life is related to tool wear, changes in the size of the workpiece being processed, surface quality, cutting noise, processing heat, etc. When determining the processing conditions, research needs to be conducted based on the actual situation. For difficult-to-process materials such as stainless steel and heat-resistant alloys, coolant can be used or a rigid blade can be selected.

When roughing, tools with high strength and durability should be selected to meet the requirements of large back cutting and feed rates during rough machining.

When finishing, tools with high precision and durability should be selected to ensure the requirements of machining accuracy.

Machine tools and machine tool inserts should be used as much as possible to reduce the time for changing tools and facilitate tool alignment.

For CNC turning, universal fixtures should be used to clamp workpieces as much as possible and avoid using special fixtures;

The positioning reference of the parts should coincide to reduce positioning errors.

The processing route refers to the trajectory and direction of the tool relative to the workpiece during the CNC machine tool processing process.

It should be able to ensure the requirements of machining accuracy and surface roughness;

The processing route should be shortened as much as possible to reduce the tool's idle travel time.

At present, when CNC turning has not yet reached conditions for universal use, excessive allowances on the workpiece, especially those containing forging or casting hardened layers, should be machined on an ordinary lathe. If it is necessary to use a numerical control lathe for machining, the program should be flexibly arranged.

Currently, the connection between the hydraulic chuck and the hydraulic clamping cylinder is realized through pull rods. The key points for clamping the hydraulic chuck are as follows: First, remove the nut on the hydraulic cylinder, remove the pull rod, and pull it out from the end of the main spindle, and then remove the fixing screws of the chuck to remove the chuck.

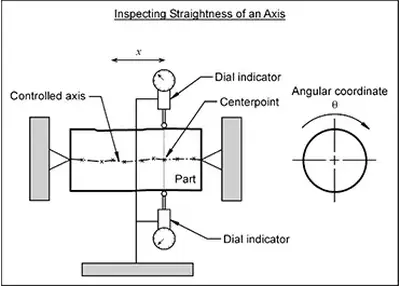

Unlocking Precision in CNC Machining: Understanding Straightness and FlatnessNovember 17, 2023As a leading precision machine shop, Richconn stands committed to delivering unrivaled precision and excellence in every aspect of our work. Dive into the world of geometric accuracy with us as we explore the pivotal concepts of "straightness" and "flatness" in CNC machining.view

Unlocking Precision in CNC Machining: Understanding Straightness and FlatnessNovember 17, 2023As a leading precision machine shop, Richconn stands committed to delivering unrivaled precision and excellence in every aspect of our work. Dive into the world of geometric accuracy with us as we explore the pivotal concepts of "straightness" and "flatness" in CNC machining.view Everything You Need to Know About CNC Machine ShopSeptember 13, 2023Are you looking to find a CNC machine shop in China? This article covers the information you need to know and helps you choose the best partner.view

Everything You Need to Know About CNC Machine ShopSeptember 13, 2023Are you looking to find a CNC machine shop in China? This article covers the information you need to know and helps you choose the best partner.view Brass vs Bronze vs Pure Copper vs Copper Alloys: An in-depth look at their differencesSeptember 26, 2023The comparison of brass to bronze to copper and its copper alloys is crucial as these metals can be easily confused. In addition, the distinction between these materials is also very subtle. As a result, development engineers or designers can be seriously confused when it comes to material selection. In particular, the similarity of these metal constituent elements makes it more difficult to classify and select them.view

Brass vs Bronze vs Pure Copper vs Copper Alloys: An in-depth look at their differencesSeptember 26, 2023The comparison of brass to bronze to copper and its copper alloys is crucial as these metals can be easily confused. In addition, the distinction between these materials is also very subtle. As a result, development engineers or designers can be seriously confused when it comes to material selection. In particular, the similarity of these metal constituent elements makes it more difficult to classify and select them.view Titanium vs Stainless Steel: Choosing the Right Material for Your MachiningNovember 24, 2023Understand the differences between titanium and stainless steel and choose the best material for CNC machining.view

Titanium vs Stainless Steel: Choosing the Right Material for Your MachiningNovember 24, 2023Understand the differences between titanium and stainless steel and choose the best material for CNC machining.view Spray painting, powder spraying, electrophoresis: three common surface treatment methodsMarch 6, 2024Spray painting is a common way of surface treatment, its principle is to use air pressure to spray paint from the nozzle, forming tiny droplets, that and evenly attached to the surface of the painted object.view

Spray painting, powder spraying, electrophoresis: three common surface treatment methodsMarch 6, 2024Spray painting is a common way of surface treatment, its principle is to use air pressure to spray paint from the nozzle, forming tiny droplets, that and evenly attached to the surface of the painted object.view Richconn 2024 Chinese New Year Holiday NoticeJanuary 2, 2024January 02, 2024Chinese New Year is approaching! We would like to remind you that Richconn will be on holiday to celebrate our Chinese New Year. For your convenience in arranging your project, please ...view

Richconn 2024 Chinese New Year Holiday NoticeJanuary 2, 2024January 02, 2024Chinese New Year is approaching! We would like to remind you that Richconn will be on holiday to celebrate our Chinese New Year. For your convenience in arranging your project, please ...view

EN

EN

ru

ru