Anodizing goes beyond surface enhancement; it represents an extraordinary electrochemical transformation that endows a diverse range of metals with exceptional characteristics. If you've ever wondered, "What is anodizing?" or are seeking insights into the anodizing process, anodizing machines, how anodizing works, and the different types of anodizing, you're in the right place.

Anodizing is a versatile and essential process used across various industries to enhance the durability, appearance, and functionality of metal parts.

Anodizing isn't a recent innovation; it has a rich history that spans nearly a century. It was first patented in 1923 by Bengt E. J. Nordstrom and Auguste W. Bunge in Switzerland. Since then, it has continually evolved and been refined by researchers and industries worldwide, becoming one of the most widely used and trusted surface treatment methods for metal components.

At its core, anodizing is an electrochemical process that creates a robust oxide layer on the surface of metal parts. This process occurs through a carefully controlled reaction between the metal and an acid solution. The resulting oxide layer is characterized by its hardness, porosity, and strong adhesion to the metal substrate. The thickness, color, and specific properties of this layer can be precisely controlled by adjusting various parameters during the anodizing process.

Primarily, anodizing finds its stronghold in aluminum alloys, widely utilized in diverse sectors such as aerospace, automotive, construction, electronics, medical, military, and consumer goods.

Why is it so indispensable? Here are some general benefits of Anodizing:

Corrosion and Wear Protection

Elevating Visual Appeal

Reinforcing Mechanical Characteristics

Each stage in the anodizing process holds significance and plays a crucial role.

Step 1: Cleaning

The anodizing process begins with a meticulous cleaning of the metal part. A degreasing agent, such as soap or detergent, is used to remove any dirt, oil, or grease from the surface.

Step 2: Etching

After cleaning, the metal part undergoes an etching process. Mild acids, such as sodium hydroxide or sulfuric acid, are commonly used for this purpose. The goal is to remove any existing oxide film or surface irregularities from the metal's surface.

Step 3: Anodizing

The metal part is immersed in an acid electrolyte bath, which can include acids like sulfuric acid, chromic acid, or oxalic acid. The metal part is connected to a direct current (DC) power source. In this configuration, the metal component acts as the anode or positive electrode. Within the electrolyte bath, the metal part attracts oxygen ions from the solution due to the electrical current flowing through the circuit. These oxygen ions react with the metal atoms on the surface, resulting in the formation of a hard and porous oxide layer on the metal part. The thickness and porosity of this oxide layer are precisely controlled by adjusting variables such as the type of acid, voltage, current, temperature, and the duration of the anodizing process.

Step 4: Coloring

Two common methods are employed:

Dyeing: In this process, the metal part is immersed in a solution containing organic or inorganic dyes. These dyes penetrate into the pores of the oxide layer, creating a wide range of colors and effects.

Electrocoloring: An alternative method involves applying an alternating current (AC) to the metal part while it is immersed in a solution containing metal salts. As the AC current flows, metal ions from the solution deposit into the pores of the oxide layer, producing various colors and effects.

Step 5: Sealing

The final step in the anodizing process is sealing, which serves to enhance the durability and corrosion resistance of the anodic oxide layer.

Anodizing is not a one-size-fits-all process; it comes in several types, each tailored to specific applications and requirements.

Type I (chromic acid anodize)

This type of anodizing uses chromic acid as the electrolyte and produces a thin (0.5 to 1.8 microns) and transparent oxide layer on the metal surface. It is mainly used for corrosion protection and paint adhesion for aluminum alloys that are difficult to anodize, such as high-silicon castings and welding joints.

Type II (sulfuric acid anodize)

This type of anodizing uses sulfuric acid as the electrolyte and produces a thicker (1.8 to 25 microns) and more porous oxide layer on the metal surface. It is the most common and versatile type of anodizing, as it can be dyed or electrocolored to create various colors and effects.

Type III (hard anodize or hard coat)

This type of anodizing uses sulfuric acid as the electrolyte and produces a very thick (25 to 150 microns) and dense oxide layer on the metal surface. It is also known as hard anodize or hard coat, as it increases the hardness, abrasion resistance, and corrosion resistance of aluminum parts. It is mainly used for heavy-duty applications, such as aerospace, military, and industrial equipment.

Anodizing machines are designed to provide the necessary voltage, current, temperature control, and timing required for the process. The efficiency and precision of anodizing rely heavily on the equipment used.

Fully-automated Machines

Fully automated anodizing machines are equipped with programmable logic controllers (PLCs) that can control the movement, speed, and sequence of the metal parts through the anodizing process. They can also monitor and adjust the voltage, current, temperature, and time of each anodizing step. Fully automated anodizing machines can increase the productivity, consistency, and quality of the anodized parts, as well as reduce the labor and human error involved.

Semi-automatic Anodizing Machines

Semi-automatic anodizing machines are similar to fully automated ones, except that they require some manual intervention or supervision from the operators. For example, the operators may need to load and unload the metal parts or switch between different anodizing modes or recipes. Semi-automatic anodizing machines can offer some flexibility and customization for the anodizing process, as well as reduce the initial cost and maintenance of the equipment.

Manual Anodizing Machines

Manual anodizing machines are the simplest and most basic type of anodizing equipment. They consist of a power supply, a rectifier, a timer, and a temperature controller that can be manually adjusted by the operators. The operators also need to manually move the metal parts through the anodizing process using racks, baskets, or hooks. Manual anodizing machines can be suitable for small-scale or low-volume production, or for special or complex parts that require more attention and care.

Navigating the array of anodizing machine options can be a daunting task, especially when striving for the ideal balance of efficiency, precision, and cost-effectiveness. This is where Richconn steps in as your trusted partner, offering tailored anodizing solutions to address your specific needs and alleviate any confusion surrounding machine choices.

Pros:

Richconn offers anodizing services for various metal parts, such as aluminum, titanium, zinc, magnesium, and more.

Richconn has advanced and automated anodizing machines that can control the voltage, current, temperature, and time of the anodizing process.

Richconn has strict quality control and inspection procedures for its anodized parts. Richconn can test the hardness, wear resistance, corrosion resistance, adhesion, and colorfastness of the oxide layer.

Don't hesitate to get your custom anodizing services NOW >>>

Anodizing is a transformative electrochemical process that imparts exceptional attributes to a wide range of metals. Through meticulous steps of cleaning, etching, anodizing, coloring, and sealing, metals acquire enhanced durability, corrosion resistance, and aesthetic appeal. With a wealth of experience, advanced technology, and rigorous quality control, Richconn stands as a beacon of trust, guiding you through the intricate landscape of anodizing processes and machine choices.

Unlocking Precision: A Comprehensive Guide to Machining KeywaysNovember 15, 2023Welcome to the definitive guide on keyway machining, where precision meets performance. In this in-depth exploration, we will unravel the complexities of keyway machining, providing you with practical insights, expert tips, and real-world applications. Whether you're an engineer seeking mastery or an enthusiast eager to delve into the intricacies, this guide promises a thorough journey through the world of keyway machining.view

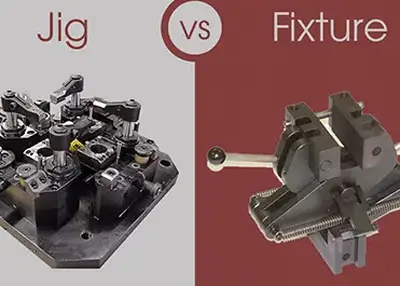

Unlocking Precision: A Comprehensive Guide to Machining KeywaysNovember 15, 2023Welcome to the definitive guide on keyway machining, where precision meets performance. In this in-depth exploration, we will unravel the complexities of keyway machining, providing you with practical insights, expert tips, and real-world applications. Whether you're an engineer seeking mastery or an enthusiast eager to delve into the intricacies, this guide promises a thorough journey through the world of keyway machining.view Jig vs Fixture: Understanding the Differences and Applications of Two Common Workholding DevicesDecember 1, 2023Jig vs Fixture is a common topic in manufacturing and engineering. Jigs and fixtures are two types of devices that are used to hold, support, and locate workpieces during machining or assembly processes. However, they have some differences in their design, function, and application.view

Jig vs Fixture: Understanding the Differences and Applications of Two Common Workholding DevicesDecember 1, 2023Jig vs Fixture is a common topic in manufacturing and engineering. Jigs and fixtures are two types of devices that are used to hold, support, and locate workpieces during machining or assembly processes. However, they have some differences in their design, function, and application.view Deburring Guide: Everything You Need to Know about DeburringNovember 2, 2023This deburring guide helps you get the best understanding of the deburring process. Learn more to eliminate the part burrs.view

Deburring Guide: Everything You Need to Know about DeburringNovember 2, 2023This deburring guide helps you get the best understanding of the deburring process. Learn more to eliminate the part burrs.view The Difference Between Nickel Plated Rolls and Chrome Plated Rolls:A Comprehensive Comparison GuideAugust 3, 2023Nickel plated rollers and chrome plated rollers are two common electroplated roller products, widely used in printing, electronics, automobiles and other industries. Do you know the differences betwee...view

The Difference Between Nickel Plated Rolls and Chrome Plated Rolls:A Comprehensive Comparison GuideAugust 3, 2023Nickel plated rollers and chrome plated rollers are two common electroplated roller products, widely used in printing, electronics, automobiles and other industries. Do you know the differences betwee...view Different Types of Lathe Tools for CNC Lathe Machine and ApplicationsJanuary 10, 2024What are lathe tools? What are their essential components, types and classifications? Trust Richconn as your reliable partner for CNC machining solutions.view

Different Types of Lathe Tools for CNC Lathe Machine and ApplicationsJanuary 10, 2024What are lathe tools? What are their essential components, types and classifications? Trust Richconn as your reliable partner for CNC machining solutions.view How to Choose CNC Machining Service Provider?October 25, 2023This article covers everything you need to know about quality control in your CNC machine shop. It will serve as a guide to help you quickly identify machine shops that you should work with and must avoid.view

How to Choose CNC Machining Service Provider?October 25, 2023This article covers everything you need to know about quality control in your CNC machine shop. It will serve as a guide to help you quickly identify machine shops that you should work with and must avoid.view

EN

EN

ru

ru