Driving down the road in the not-so-distant future will be an experience unlike any other. As advances in technology continue to shape the automotive industry, one particular innovation is set to revolutionize the way vehicles are manufactured – CNC automotive parts. With precision, efficiency, and a multitude of benefits to offer, CNC technology is leading the charge towards the next generation of vehicles. In this blog, we will explore the future of driving with CNC automotive parts and delve into the advantages they bring to the industry.

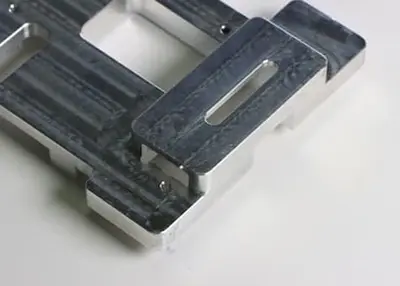

CNC, short for Computer Numerical Control, refers to the use of computer-controlled machinery for precise and automated manufacturing processes. In the automotive industry, CNC technology has rapidly gained prominence due to its ability to create highly accurate and intricate components. CNC automotive parts are created through the systematic removal of excess material from a solid block, resulting in flawless and durable finished products. From engine components to intricate interior details, CNC technology enables the production of parts with exceptional precision.

The utilization of CNC automotive parts brings numerous advantages to the manufacturing process. Firstly, CNC technology relies on computer-guided machines, eliminating the human error factor and ensuring consistent and standardized production. This accuracy translates into improved safety for drivers and increased reliability of automotive systems.

Secondly, CNC automotive parts enhance efficiency and reduce production time. Traditional manufacturing methods often require multiple iterations and manual adjustments, leading to time-consuming and costly processes. However, CNC technology allows for quick and seamless production, reducing lead times and enabling manufacturers to meet the demands of the ever-evolving automotive industry.

Finally, CNC technology offers versatility in design and customization. With CNC machines, it is possible to create complex and unique automotive parts that were once deemed implausible. Manufacturers can experiment with different materials, shapes, and textures, resulting in vehicles with unparalleled aesthetics and functionality.

As CNC automotive parts become increasingly prevalent, the driving experience is set to transform. The next generation of vehicles will boast enhanced performance, improved fuel efficiency, and reduced emissions. CNC-manufactured engine components allow for precise tolerances and optimized designs, resulting in engines that achieve unprecedented levels of power and performance while minimizing fuel consumption.

Moreover, the integration of CNC technology in the manufacturing process enables the production of lightweight materials. This facilitates the development of electric and hybrid vehicles that maximize battery performance, extend driving ranges, and contribute to sustainable mobility solutions.

In embracing CNC technology, manufacturers and consumers alike are paving the way for a future of driving that prioritizes precision, efficiency, and innovation. The benefits of CNC automotive parts extend beyond the manufacturing process, with potential cost savings for consumers due to reduced maintenance and longer-lasting components.

Furthermore, the increased customization options offered by CNC technology will allow drivers to personalize their vehicles like never before. From unique interior designs to personalized exterior features, automotive enthusiasts can now realize their individual tastes and preferences in their vehicles.

In conclusion, CNC automotive parts are revolutionizing the automotive industry and propelling us towards the future of driving. The precision, efficiency, and versatility of CNC technology enable the production of next-gen vehicles that offer enhanced performance, reduced emissions, and an unparalleled driving experience. As this technology continues to evolve, we can anticipate exciting advancements that will shape the future of mobility and transport.

Introduction to MetalworkingOctober 24, 2023Humans have developed many methods of metal fabrication, which is the processing of metal into various shape types. Here we will introduce some of the concepts and processes of this metal working method.view

Introduction to MetalworkingOctober 24, 2023Humans have developed many methods of metal fabrication, which is the processing of metal into various shape types. Here we will introduce some of the concepts and processes of this metal working method.view CNC Milling Definition Guide (Latest Insights for 2023)September 8, 2023CNC milling is a process of using a computer-controlled rotating cutting tool to remove material from a workpiece and create a custom-designed part or product. Milling is one of the most common types ...view

CNC Milling Definition Guide (Latest Insights for 2023)September 8, 2023CNC milling is a process of using a computer-controlled rotating cutting tool to remove material from a workpiece and create a custom-designed part or product. Milling is one of the most common types ...view Manufacturing Process and Selection Guide for CNC Processing iPhone CasesNovember 14, 2023In a world where Precision Machining innovation, Richconn stands as a pioneer in CNC machining technology, redefining the landscape of iPhone protection. Dive into the intricacies of CNC machining for iPhone cases and discover a realm where design meets durability, guided by a commitment to excellence.view

Manufacturing Process and Selection Guide for CNC Processing iPhone CasesNovember 14, 2023In a world where Precision Machining innovation, Richconn stands as a pioneer in CNC machining technology, redefining the landscape of iPhone protection. Dive into the intricacies of CNC machining for iPhone cases and discover a realm where design meets durability, guided by a commitment to excellence.view All About Hardness Definition: Types, Testing Methods & UnitsOctober 12, 2023Here is an in-depth overview of hardness definition. Follow this article to learn metal hardness for different materials and choose the suitable one for your project.view

All About Hardness Definition: Types, Testing Methods & UnitsOctober 12, 2023Here is an in-depth overview of hardness definition. Follow this article to learn metal hardness for different materials and choose the suitable one for your project.view Cutting Costs, Not Quality: Exploring the Best Cheap CNC Material OptionsDecember 4, 2023In today's competitive market, every business is constantly finding ways to cut costs without compromising the quality of their products or services. When it comes to CNC machining, one of the mos...view

Cutting Costs, Not Quality: Exploring the Best Cheap CNC Material OptionsDecember 4, 2023In today's competitive market, every business is constantly finding ways to cut costs without compromising the quality of their products or services. When it comes to CNC machining, one of the mos...view Analysis of the Advantages and Characteristics of 4-axis Machining Center ProcessingOctober 24, 2022At present, there are many methods and equipment used in machining centers, among which CNC four-axis machining centers are a more common machining method. Initially, three-axis machining was generall...view

Analysis of the Advantages and Characteristics of 4-axis Machining Center ProcessingOctober 24, 2022At present, there are many methods and equipment used in machining centers, among which CNC four-axis machining centers are a more common machining method. Initially, three-axis machining was generall...view

EN

EN

ru

ru