The field of machining covers a variety of complex processes, of which wire EDM is an important one. This precision cutting method processes electrically conductive materials into high-precision parts by means of electric spark discharge. In this article, we will take an in-depth look at the working principles of wire EDM, its areas of application and its importance in manufacturing.

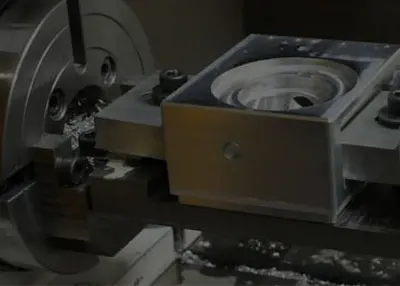

Wire EDM, also known as Electrical Discharge Machining (EDM), is a non-contact machining method that cuts a conductive workpiece into a desired shape. The basic principle is to create an electrical discharge between the workpiece and the electrode, removing the workpiece material layer by layer by means of a high-temperature, high-energy electric spark to form the desired part. The following are the key points of wire EDM:

WEDM involves two key elements: the workpiece and the electrode. The workpiece is the material to be machined, usually a material with good electrical conductivity, such as a metal or alloy. The electrode is a thin wire that has the same contour as the workpiece, but is slightly smaller than the workpiece.

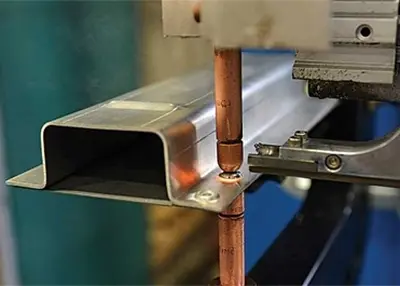

The core of the WEDM process is the discharge process. The gap between the electrode and the workpiece is filled with a medium, usually alcohol or deionized water. By applying a voltage, the electrode is brought close to the workpiece and an electric field is formed. When the strength of the electric field is high enough, an electric spark is generated between the two, melting and vaporizing the material of the workpiece, thus removing a small layer of material from the workpiece.

Wire EDM is a layer-by-layer process. The workpiece and electrode move gradually between each layer, with each discharge removing a layer of material. This process continues until the workpiece reaches the desired shape.

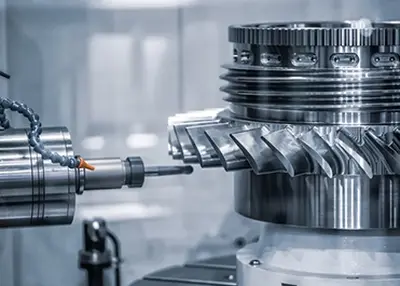

WEDM is well suited for the manufacture of parts that require high precision. Due to its non-contact nature, no mechanical stresses are generated, thus allowing for the manufacture of very fine and complex parts.

WEDM is a versatile cutting technology that is suitable for many industries and applications, including but not limited to:

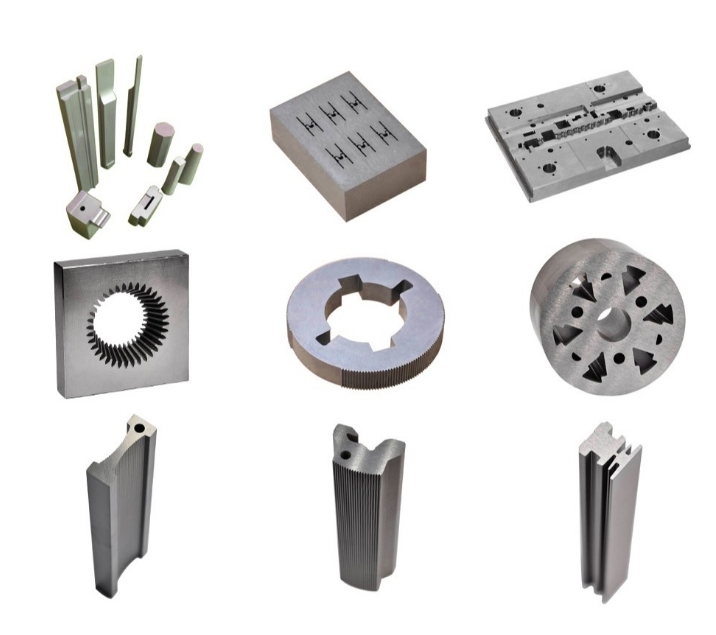

WEDM is widely used in mold manufacturing, such as plastic injection molding dies, die casting dies and stamping dies. It creates precise mold contours and tiny holes to ensure the quality of the final product.

The aerospace field requires high precision machcining parts and components, and WEDM can produce a variety of aero-engine components, aerospace instruments and equipment.

The manufacture of medical devices and instruments often requires highly precise parts for surgical tools, artificial joints and implants.

The electronics field requires precise connectors, electrically conductive components, and microstructures, and wire EDM can fulfill these requirements.

WEDM is also used in the manufacture of fine art and jewelry, as it allows for the creation of tiny, intricate designs.

WEDM plays a key role in modern manufacturing as it allows for the creation of high-precision, intricately shaped parts that meet the needs of a variety of industries. It is an indispensable technology that has helped drive innovation and progress, accelerating product development and manufacturing. As technology continues to evolve, wire EDM will continue to bring more opportunities and challenges to the manufacturing industry.

The Differences Between Riveting vs WeldingFebruary 18, 2024Let's explore the advantages, applications, and limitations of riveting and welding processes. Then, you can select the right method for assembling sheet metal parts.view

The Differences Between Riveting vs WeldingFebruary 18, 2024Let's explore the advantages, applications, and limitations of riveting and welding processes. Then, you can select the right method for assembling sheet metal parts.view![Chamfer 101: Understanding Chamfers and Chamfered Edge [Quick Guide]](/uploads/image/20231123/14/chamfer-101-understanding-chamfers-and-chamfered-edge-quick-guide_400x400.webp) Chamfer 101: Understanding Chamfers and Chamfered Edge [Quick Guide]November 23, 2023Gain comprehensive knowledge about chamfers, including types, advantages and limitations, various methods of measurement and a comparative feature analysis.view

Chamfer 101: Understanding Chamfers and Chamfered Edge [Quick Guide]November 23, 2023Gain comprehensive knowledge about chamfers, including types, advantages and limitations, various methods of measurement and a comparative feature analysis.view How Are Tolerances in Machining Created?October 26, 2023Parts in the processing process, due to various reasons, processing and manufacturing of parts size can not be exactly the same as the size of the parts drawing design, the degree of deviation between the actual geometric parameters and the ideal geometric parameters for the parts processing error.view

How Are Tolerances in Machining Created?October 26, 2023Parts in the processing process, due to various reasons, processing and manufacturing of parts size can not be exactly the same as the size of the parts drawing design, the degree of deviation between the actual geometric parameters and the ideal geometric parameters for the parts processing error.view Precision at Work: CNC Advancements in the Electronic SectorJuly 2, 2024Let’s discover the great impact of CNC technology in the electronic sector. Explore how precision, efficiency, and innovation converge to reshape electronic manufacturing processes, driving advancements and elevating industry standards to new heights.view

Precision at Work: CNC Advancements in the Electronic SectorJuly 2, 2024Let’s discover the great impact of CNC technology in the electronic sector. Explore how precision, efficiency, and innovation converge to reshape electronic manufacturing processes, driving advancements and elevating industry standards to new heights.view The Ultimate Guide on Aluminum Die Casting 2024August 2, 2023Nowadays, aluminum die casting is widely used in various industries like automotive, industrial, and telecommunications. It’s often used to produce electrical, hydraulic, lighting components, etc. No...view

The Ultimate Guide on Aluminum Die Casting 2024August 2, 2023Nowadays, aluminum die casting is widely used in various industries like automotive, industrial, and telecommunications. It’s often used to produce electrical, hydraulic, lighting components, etc. No...view Waterjet Cutting: Methods, Applications, and BenefitsJune 21, 2024Waterjet cutting is a special cutting technique that is progressively drawing interest from an increasing number of industries. The technical underpinnings, benefits, and areas of application of waterjet cutting will be thoroughly covered in this article.view

Waterjet Cutting: Methods, Applications, and BenefitsJune 21, 2024Waterjet cutting is a special cutting technique that is progressively drawing interest from an increasing number of industries. The technical underpinnings, benefits, and areas of application of waterjet cutting will be thoroughly covered in this article.view

EN

EN

ru

ru