If you've ever left a food container in the microwave for too long, you know that some plastics don't tolerate high temperatures very well. Depending on the type of container, you might be storing the food from the night before in polypropylene (PP), polycarbonate (PC) or polyethylene (PE), none of which excel at heat resistance. Polypropylene, for example, begins to lose strength at 82 °C. Polyethylene does better there at 130 °C, but even so-called "high-temperature" polycarbonate is only approved up to 140 °C.

As the tiny microwave symbol on the back of these containers indicates, each of the polymers just listed is clearly suitable for reheating leftovers. For high-temperature applications, however, something more robust is needed. But what does that mean, exactly? In other words: How hot is hot? The exact answer depends on the application requirements. For the purposes of this design tip, we define a value above 175 °C.

Also, we want to clarify that in most cases we are talking about working temperatures, not temperatures required to melt or crystallize the polymer. This topic is discussed elsewhere on our website. We also do not discuss the flame retardant properties of a polymer. As you will see, this important property has little to do with the heat resistance of a polymer.

Consider acrylonitrile butadiene styrene, a common plastic you may know as ABS. Popular with plumbers and toy manufacturers, ABS has a Vicat softening temperature - the temperature at which the material loses its "stable form" - of about 104 °C and a heat deflection temperature of only 94 °C. Adding an organic halogenated compound or other flame-retardant compound drops these values significantly, although the material is much less flammable.

So what are some of these high-temperature polymers? Let's start with polytetrafluoroethylene (PTFE), better known by its trade name Teflon®. PTFE was discovered by accident at DuPont in 1938 and begins to lose its properties at a temperature of about 260 °C. And despite the aforementioned flame retardancy characteristics, PTFE also has an admirable V-0 rating. Although the vapors are chemically stable and non-toxic at lower temperatures, protection from them should be considered when the temperature could exceed 350 °C. The polymer is hydrophobic (water repellent) and has one of the lowest coefficients of friction of any plastic (making it extremely slippery). It is also highly resistant to most acids, solvents and other corrosive chemicals.

PTFE is often used as a coating for carpets and clothing, but its low coefficient of friction also makes it an excellent choice for components such as bearing blocks and housings. PTFE is relatively soft and therefore easy to machine, but has lower dimensional stability due to its thermal expansion. However, because it does not flow when heated above its melting point of 327 °C, it cannot be used in plastic injection molding or 3D printing.

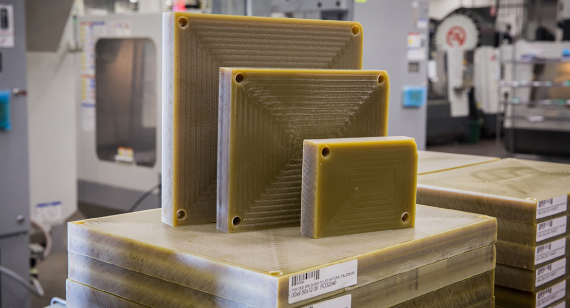

One heat-resistant thermoplastic that can be both machined and injection molded is polyetheretherketone (PEEK). With a melting point close to that of PTFE, PEEK retains its quite excellent mechanical properties at temperatures of 250 °C or higher (up to 300 °C for short periods). It is also resistant to radiation, chemical attack and hydrolysis. The latter property means that PEEK can be sterilized in an autoclave. This makes it ideal for use in spinal implants and fixation devices in the medical industry. These properties also make it a food-grade polymer.

PEEK has good dielectric strength and is therefore often used as an electrical insulator in semiconductor applications. It is not quite as "slippery" as PTFE, but still has a low coefficient of friction and is very wear resistant. It is often used in automotive seals, wear rings and bearing surfaces. And thanks to its high strength-to-weight ratio and other physical properties, PEEK often replaces metal alloys in various aircraft components (with a density of 1.32, it has only 1/5 the weight of steel (8) and is less than half the weight of most aluminum alloys (3)). Like PTFE, PEEK is a very special material ...

The same is true for polyphenylene sulfide (PPS). Although it cannot compete with PEEK and PTFE in terms of thermal properties, it still offers a respectable working temperature of 220 °C. This thermoplastic, known to automotive and electrical engineers as Ryton®, offers a good combination of corrosion resistance, mechanical strength and dielectric properties. It also flows quite well during plastic injection molding and has a minimal shrinkage rate. This makes it a good choice for use in precision electrical connectors and similar components.

PPS is not a candidate for CNC machined parts, but PPSU is. Polyphenylsulfone (also known as Radel®) has a working temperature quite close to that of PPS, has similar mechanical and electrical properties, can be sterilized, and is easy to machine. It is used for window surrounds in aircraft, handles for surgical instruments, and hot water fittings. Since it is FDA-compliant (like the other polymers mentioned so far), it is suitable for direct contact with food.

Polyetherimide (PEI), also known as Ultem, is similar. PEI is both machinable and suitable for injection molding and is available in various glass fill (GF) grades. With a maximum continuous operating temperature of 171 °C, Ultem may not be suitable for cookie baking, but it is an excellent general-purpose polymer for applications requiring strength, stiffness, solvent and flame resistance, and dielectric properties.

Other notable high-temperature polymers include Vectra, a type of injection-moldable liquid crystalline polymer (LCP) commonly used in the SMT (surface mount technology) industry. It has excellent flow properties, can produce parts with very thin walls, and has a working range of up to 240 °C. Furthermore, there is PC/PBT, a blend of polycarbonate and polybutylene terephthalate that can withstand temperatures of up to 130 °C - not nearly as good as the counterparts described so far, but still with a good balance between toughness and weatherability, especially when low temperatures are a problem (like -40 °F, which is also -40 °C).

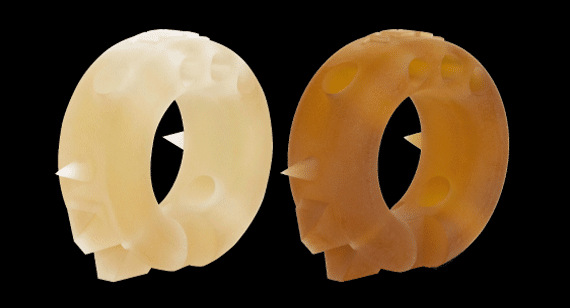

Now you may be thinking, "But what about 3D printed parts? What are the options here for high-temperature materials?" You're in luck. Chief among them is a ceramic-like advanced high-temperature stereolithography resin (PerFORM) that can withstand temperatures of up to 268 °C after an optional post-cure process. This gives designers the ability to prototype strong, rigid parts for applications such as wind tunnel testing, rapid tooling, electronic enclosures and more. Similarly, the PC-like Advanced High-Temp (Accura 5530) is a translucent material that combines optical clarity with good heat resistance. And like the polycarbonates used for machined and injection-molded components, Accura 5530 resists water, chemicals, fire and electrical effects.

Because each of the engineering polymers discussed here is both strong and stable, you have little to worry about in terms of design for feasibility. Some are more abrasive than others and require the use of carbide drills and cutters, while those with very high melting temperatures may require some adjustments to the plastic injection molding process. However, since all are listed as standard Richconn materials, you will receive feedback during the online quoting process.

We encourage you to review the extensive list of material data sheets on our website for more details. With more than 140 polymers and 30 types of elastomers or liquid silicones (LSRs) - some of which can withstand fairly high temperatures - there's sure to be the perfect material for your next project. If you have any questions, drop us a line. Our application engineers are always available at +86-0755-28025755 or sales@richconn.com.cn.

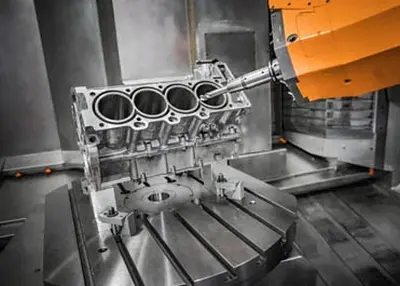

Three Things You Need to Know About CNC Machining in the Energy IndustryOctober 25, 2023Before the Industrial Revolution, human beings didn't have much need for energy. For example, we were happy to use the sun's energy to heat our homes, horses for transportation, wind power to sail around the world, and water to power simple machines that ground grain.17 In the 1980s, everything changed with the rapid growth of steam-powered electric power plants, most of whose components were manufactured using high-speed machine tools.view

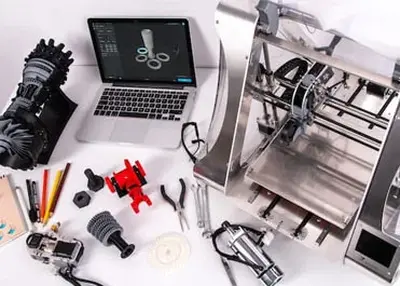

Three Things You Need to Know About CNC Machining in the Energy IndustryOctober 25, 2023Before the Industrial Revolution, human beings didn't have much need for energy. For example, we were happy to use the sun's energy to heat our homes, horses for transportation, wind power to sail around the world, and water to power simple machines that ground grain.17 In the 1980s, everything changed with the rapid growth of steam-powered electric power plants, most of whose components were manufactured using high-speed machine tools.view How Much Do 3D Prints Cost: An In-Depth Guide to ExpensesAugust 15, 20233D printing has revolutionized manufacturing and design, allowing individuals and businesses to create intricate and customized objects with unprecedented ease. However, one common question that arise...view

How Much Do 3D Prints Cost: An In-Depth Guide to ExpensesAugust 15, 20233D printing has revolutionized manufacturing and design, allowing individuals and businesses to create intricate and customized objects with unprecedented ease. However, one common question that arise...view Machined Castings - Your Comprehensive GuideNovember 7, 2023Are you looking to delve into the fascinating world of machined castings? Are you curious about how these essential components are made, their diverse applications, and the key factors to consider when choosing a supplier?view

Machined Castings - Your Comprehensive GuideNovember 7, 2023Are you looking to delve into the fascinating world of machined castings? Are you curious about how these essential components are made, their diverse applications, and the key factors to consider when choosing a supplier?view Common Inspection Tools and Methods for CNC Parts: Ensuring Quality and PrecisionJune 21, 2024Learn about common inspection tools and methods in CNC machining, such as calipers, micrometers, gauges, projectors, and CMM. Discover how to use these tools accurately for quality control.view

Common Inspection Tools and Methods for CNC Parts: Ensuring Quality and PrecisionJune 21, 2024Learn about common inspection tools and methods in CNC machining, such as calipers, micrometers, gauges, projectors, and CMM. Discover how to use these tools accurately for quality control.view Fillet Meaning: What Are Fillets in CNC Manufacturing?September 27, 2023Fillets are rounded corners that help increase strength and prevent rapid deformation at a part’s corners. Take a look at the fillet definition!view

Fillet Meaning: What Are Fillets in CNC Manufacturing?September 27, 2023Fillets are rounded corners that help increase strength and prevent rapid deformation at a part’s corners. Take a look at the fillet definition!view What Are The Characteristics and Features of CNC Machining?June 21, 2022Process concentration, automation, high flexibility, and strong capabilities are the characteristics of CNC machining. The process rules of CNC machining and traditional machine tool machining are gen...view

What Are The Characteristics and Features of CNC Machining?June 21, 2022Process concentration, automation, high flexibility, and strong capabilities are the characteristics of CNC machining. The process rules of CNC machining and traditional machine tool machining are gen...view

EN

EN

ru

ru