This article covers everything you need to know about quality control in your CNC machine shop. It will serve as a guide to help you quickly identify machine shops that you should work with and must avoid.

When gathering information about any precision machine shop supplier you are considering, you must first visit the certifications they have obtained. One important certification you must look for is ISO 9001.

ISO 9001 is a standard that specifies requirements for a quality management system. An ISO 9001 certified machine shop strictly adheres to legal and regulatory requirements to ensure high quality machining services.

Once you have confirmed that a machine shop's certification meets your requirements, you must determine the type of CNC machining equipment they have in their facility.

The type of CNC machine used to create the prototype (or production) part plays a significant role in the quality of the part you receive.There are several types of CNC machines, often categorized by the number of axes they can run, such as 2-axis, 3-axis, 4-axis, and 5-axis CNC machines.

As one might imagine, 5-axis CNC machining is more advanced than 2-, 3- and 4-axis CNC machines. They offer better relational accuracy, surface finish, and more importantly, the ability to machine complex shapes. Not all parts require 5-axis machining, but if the part is complex enough, it may be the ideal solution.

Third-party machining suppliers that utilize advanced CNC machining technology in their facilities seek to ensure the high quality of machined parts. But that's not all you should look for in a third-party machining supplier!

The quality of machined parts also depends heavily on the expertise of the CNC operator who makes the part.

.jpg)

Despite manufacturers boasting about having certified and state-of-the-art machining equipment, there are many horror stories of customers receiving low-quality and unusable CNC machined parts. Often, these problems can be traced back to the CNC machine operator.

The fact is, there is a skills gap among CNC machine operators. The machining market is filled with operators who have learned their lessons the "hard way" and are prone to making the same machining mistakes over and over again.

To complicate matters, many machine shops lack a standard quality management system to check the parts being made by operators or technicians. You must avoid these types of suppliers.

Top machine shops typically perform three types of inspections at different stages of a manufacturing project:

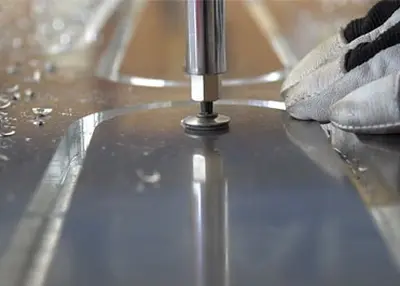

Machine Operator Inspection: Operators perform a variety of item inspections during (or immediately after) machining to identify tolerance issues. It involves the use of simple measuring tools such as through/stop gauges and micrometers.

Inspection by In-Process Probing: Describes an automated method of verifying critical features and tolerances of a part during CNC machining using programmed probes. These probes automatically monitor the process and adjust work coordinates and cutting tools accordingly.

Inspection by the Quality Control (QC) Department: describes the inspection phase of a CNC machined part performed by a team of QC specialists. These QC specialists utilize height gauges, microscopes, 2D projectors, micrometers, and Coordinate Measuring Machines (CMMs) to ensure that the part meets the customer's requirements.

When choosing a CNC machining service provider, make sure you consider the key factors outlined above, including certifications, type of machining equipment, and skill level of operators. These factors will have a direct impact on the quality and performance of the parts you receive. Additionally, don't forget to ask your supplier when working with them if they perform three different types of inspections to ensure the quality of your parts. It's only by taking these factors into consideration that you'll be able to minimize the risk of quality issues and production delays, and ensure that your collaboration with your CNC machine shop is efficient and seamless. Choosing the right CNC machining service provider will have a profound impact on the success of your projects and products, so be careful.

How long does it take to CNC machine a simple part?November 1, 2023CNC machining, as an important process in the modern manufacturing field, has been widely used in various industries to realize the manufacturing of precision parts through the intelligent control of computers. In the manufacturing process, the complexity of the part has a great impact on the machining time. In this paper, we will discuss the time required for CNC machining from the perspective of simple geometry to highly complex structures, and analyze in depth the influence of geometry, machining process and related parameters on machining time.view

How long does it take to CNC machine a simple part?November 1, 2023CNC machining, as an important process in the modern manufacturing field, has been widely used in various industries to realize the manufacturing of precision parts through the intelligent control of computers. In the manufacturing process, the complexity of the part has a great impact on the machining time. In this paper, we will discuss the time required for CNC machining from the perspective of simple geometry to highly complex structures, and analyze in depth the influence of geometry, machining process and related parameters on machining time.view CNC numerical control cutting aluminum sheet, the efficient tool of modern manufacturingAugust 4, 2023In modern manufacturing, aluminum sheets are widely used, and CNC (Computer Numerical Control) cutting technology has become an efficient tool for processing aluminum sheets. CNC cutting aluminum she...view

CNC numerical control cutting aluminum sheet, the efficient tool of modern manufacturingAugust 4, 2023In modern manufacturing, aluminum sheets are widely used, and CNC (Computer Numerical Control) cutting technology has become an efficient tool for processing aluminum sheets. CNC cutting aluminum she...view 6 Avoidable Mistakes When Designing CNC PartsOctober 13, 2023A common mistake is designing parts with surfaces where material removal would actually be unnecessary. Unnecessary machining contributes to longer machining times, and that greatly impacts the final production cost.view

6 Avoidable Mistakes When Designing CNC PartsOctober 13, 2023A common mistake is designing parts with surfaces where material removal would actually be unnecessary. Unnecessary machining contributes to longer machining times, and that greatly impacts the final production cost.view Machining tips and precautions in grooving and cutting offNovember 17, 2023The cutoff and grooving process is an important part of CNC turning machining and presents many unique challenges. During the machining process, the limitations of machine tool and tool rigidity, cooling conditions, programming techniques, tool performance and many other factors can cause problems for machining efficiency, quality and safety.view

Machining tips and precautions in grooving and cutting offNovember 17, 2023The cutoff and grooving process is an important part of CNC turning machining and presents many unique challenges. During the machining process, the limitations of machine tool and tool rigidity, cooling conditions, programming techniques, tool performance and many other factors can cause problems for machining efficiency, quality and safety.view Surface Finishing Process What Are the Different Products Suitable For What Process?October 24, 2023The whole process of processing, in the selection of the appropriate processing method CNC processing or 3D printing, after the completion of processing, most of them need surface treatment. Meet the corrosion resistance, abrasion resistance, decoration or other special functional requirements of the product.view

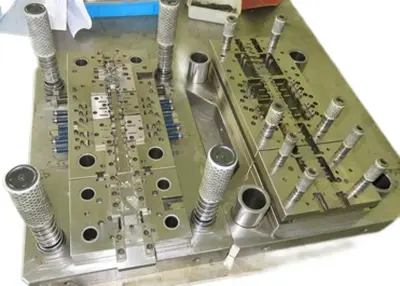

Surface Finishing Process What Are the Different Products Suitable For What Process?October 24, 2023The whole process of processing, in the selection of the appropriate processing method CNC processing or 3D printing, after the completion of processing, most of them need surface treatment. Meet the corrosion resistance, abrasion resistance, decoration or other special functional requirements of the product.view Metal Stamping Die: Professional, Speed, AdvantagesApril 25, 2023Mold products are needed in many industries. Screws and nuts that we use in our daily life, pins and patches used in the electronics industry, equipment housing and internal parts used in the medical ...view

Metal Stamping Die: Professional, Speed, AdvantagesApril 25, 2023Mold products are needed in many industries. Screws and nuts that we use in our daily life, pins and patches used in the electronics industry, equipment housing and internal parts used in the medical ...view

EN

EN

ru

ru