The main pillar of manufacturing now is Computerized Numerical Control (CNC), thanks to recent technical advancements. Despite all of its advantages, this production process requires the greatest CNC software to run smoothly. Thus, which CAD/CAM program is the best for CNC?

Excellent CAD-CAM applications are widely available for computerized numerical control. The ideal option for you would, however, rely on additional variables. These variables include price, functionality, support for CNC techniques, and compatibility with other software.

The top 7 CAD and CAM programs for CNC applications are provided below, along with information on their features and things to think about before selecting a program.

CAD-CAM technology helps to create, modify and optimize designs. Many people use the term “CAD-CAM” when talking about software that uses CNC machines to make things. But what’s the cad/caming meaning? CAD stands for Computer-Aided Design, and CAM stands for Computer-Aided Manufacturing, and both are used to design and manufacture prototypes, finished products and mass-produced products.

Let’s dive into CAD CAM meaning part! CAD stands for Computer-Aided Design and helps in making the design process seamless. Most designers use this software to create 2D and 3D designs due to its speed and accuracy. It replaces manual drafting by engineers and makes the design process more automated.

CAM, meaning Computer Aided Manufacturing, improves the accuracy of the manufacturing process. It involves manufacturing a product or workpiece with the help of computer-controlled machines. Moreover, CAM does this by converting cam design files into codes. In addition, it transmits the code to the machine, which performs manufacturing operations such as cutting, drilling or milling according to the instructions in the code.

CAD /CAM software is a software package that has both CAD and CAM functionality and it can also turn cad to cam. Therefore, instead of having to use two different software platforms to create and develop designs, operators use the same software. Below is the automated process of CAD-CAM software:

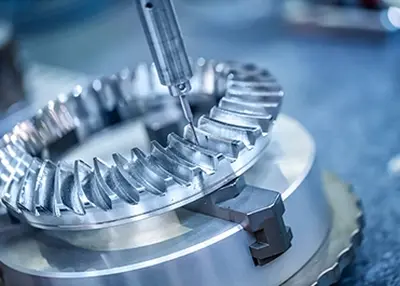

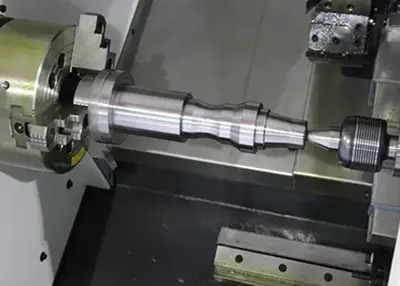

Turning: The removal of undesired material is known as CNC turning. In order to remove extra material, the workpiece is rotated using rollers and gears rather than cutting tools.

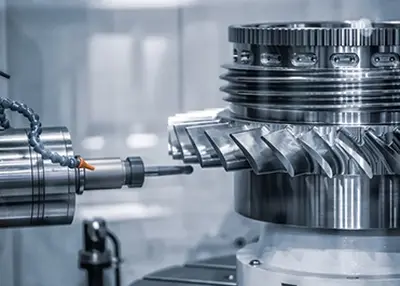

Milling: The removal of extra material is also aided by the CNC milling process. But the cutting tool eliminates the extra material, unlike turning. To get rid of extra material, CAD/CAM software uses automated procedures including drilling, grinding, and skeletonizing.

3D Printing: it is an additional automated software process, however, it uses additive technology as opposed to subtractive technology. By applying layers of material, it aids in the creation of shapes.

The Solid Edge suite of software tools advances every facet of the product development process, including manufacturing, data management, simulation, mechanical and electrical design, and cloud-based collaboration. The tools are inexpensive and simple to set up and maintain. Solid Edge, which was built on Siemens' cutting-edge technology, offers the most inventive and thorough approach to product creation for the mass market.

One of the most well-liked free CAD CAM programmer options is Fusion 360. It is the best cam software free version which CAM settings are perfect for milling and laser procedures, and it offers both CAD and CAM functions. In addition, this program supports a wide range of file formats, such as STL, DXF, and 3MF.

Fusion 360 has the ability to link your design to many manufacturing processes, including mill-turning, turning, and profiling. With this software, you may also do 4-axis milling, 5-axis milling, probing, and 2.5-axis milling.

Furthermore, this program helps you make decisions by balancing performance and cost. With production demands as its primary element, this software's prediction component assists in estimating the cost of manufacturing your design.

Fusion 360 software, one of the greatest free CAD CAM software for novices, may be used by professionals in a variety of industries, including mechanical engineers and product designers as well as machinists. But only the Windows and macOS operating systems are compatible with it.

FreeCAD is largely a CAD program, but it also offers effective CAM features. This software's CAD component aids in the creation of 2D and 3D designs. This CAD-CAM software has 3D operations, such as water lines and pockets, unlike others.

In contrast, the CAM section includes a movement studio in addition to fluid and mechanical simulations. By choosing the Path Workbench, you can use Free CAD's CAM capability.

You are free to choose from a wide range of work instruments on the Workbench, including mills, lathes, and laser cutters. Additionally, you create the G-code on the Workbench and send it to the CNC machine.

CAD and CAM features are both present in SAi's EnRoute. It may offer 2D and 3D designs that are perfect for various machine kinds. Enroute is a user-friendly software that is perfect for a variety of manufacturing tasks, including creative design work, sign creation, metal machining, carpentry, and ordinary cutting.

Its designs are perfect for usage with waterjets, plasmas, lasers, and CNC router software. Enroute is easy to use and includes ready-to-use template textures. Realistic simulations are another element of this program that helps with model testing and identifies mistakes that could interfere with manufacturing.

You can also draw freehand with this software using a mouse or pen and rely on its accurate editing features to improve your shapes. Enroute also has one of the best CAM features in the software with an automatic toolpath.

Carbide produces some of the greatest design and production software available on the market with its CAD and CAM features. A lot of capability is combined in this software, such as simulation, CAD, CAM, and G-code sender.

Additionally, it works with a variety of file formats, such as DXF and STL. The best thing about this software is that it allows you to use Carbide Develop to develop a design directly, convert it to G-code, and send it straight to your CNC machine for manufacturing.

Furthermore, Carbide Create is a versatile software that works with both Windows and macOS. The free edition of this CAD program allows users to perform 2.5D machining, which is the 2.5D dimension between 2D and 3D. Two axes can only be moved at once in 2.5D machining.

Dassault Systems' SOLIDWORKS is primarily a CAD program, although it can also handle CAM tasks. However, this software only offers a small number of CAM functions. You need to purchase an add-on that uses rule-based technology to integrate design and manufacturing in order to get the full capabilities.

In addition, this CAM add-on comes in four variants, each with unique features, so your CAM needs to figure out which version is best for you. Standard, professional, machinist professional and machinist standard are the four varieties.

Manufacturability tests, design, simulation, and cost prediction are all covered by SOLIDWORKS software. Though it is limited to Windows, it can also manage data among other things.

This program is unique in that it may be used for networking. SOLIDWORKS allows several users to collaborate on the design at the same time. Furthermore, modifications made to one step of the design process have an impact on other steps.

Applications for Exocad can be found in many different fields, including dentistry. It can handle large amounts of data and offers CAD and CAM features.

Exocad is an easy-to-use tool that lets you switch between Wizard and Expert modes based on your degree of experience. Exocad is a dental CAD program that facilitates the creation of a variety of dental goods, such as removable veneers, crowns, bridges, and inlays.

One of the most often used CAD-CAM programming choices in the dental sector is Exocad because of its capacity to increase productivity. Moreover, it finds use in a number of dental domains, such as orthodontics, design, manufacturing, planning, and scanning of implants.

This program is limited to Windows and supports file types such as.sdfa,.eoff, and.xyznb.

Selecting the best CAD/CAM software might be difficult because there is a vast selection available online. After talking about the finest software for your CAD and CAM requirements, here are some things to think about while selecting a program.

There are numerous CNC methods available, including milling, laser, and plasma. All software does not, however, support them. You should only choose software that supports the CNC processes you need for manufacturing, so be aware of them before making your choice.

The most common deterrent when selecting CAD/CAM software is cost. This is a result of the high cost of most CAD software products. Nevertheless, costly software isn't necessarily the best, so be sure to know what features you actually require.

It's also critical to remember that most software is available in versions, and that newer versions consistently outperform older ones. When buying subscription-based or lifetime-paid software, keep this in mind.

Computerized numerical control methods use a variety of file types, including STL, IGES, DXF, X3D, Parasolid, and others. In most cases, the software that created your CAD file determines the file type. If a large variety of files, both importable and exportable, are not accepted by your program, there may be an issue.

Software's feature count frequently impacts the caliber of the work it produces. Keep an eye out for software with a lot of features since it tends to minimize workloads while increasing productivity.

The compatibility of the software with other programs is an additional consideration while selecting software. The time spent preparing and transferring files between systems for manufacturing would be reduced as a result. Choose software that functions and collaborates with others without a hitch every time.

Richconn has been dedicated to offering top-notch goods and services to clients all over the world since its founding and specializes in producing unique, high-quality prototypes and parts. The company has accomplished incredible things in the machine manufacturing, electrical technology, and medical device industries because to its wealth of industry knowledge and skills.

Among the various services we offer are 3D printing and CNC machining. In order to satisfy your manufacturing needs, we provide custom part creation services. We also make sure to deliver on schedule because we understand how important time is.

To utilize our quick services, simply upload your CAD file to our site. We can get to work on your project right away after providing you with a quote.

CNC Machining Workshop: The Magic Place of Modern ManufacturingNovember 1, 2023A Numerical Control Shop is a term widely used in the manufacturing industry to refer to a factory or shop that utilizes computer technology and numerical control (NC) equipment to control and automate machining and manufacturing processes.view

CNC Machining Workshop: The Magic Place of Modern ManufacturingNovember 1, 2023A Numerical Control Shop is a term widely used in the manufacturing industry to refer to a factory or shop that utilizes computer technology and numerical control (NC) equipment to control and automate machining and manufacturing processes.view How Many Types of Gears Are There? What Common Materials Are Suitable for Making Gears?October 26, 2023Gears are mechanical parts with teeth that can mesh with each other, and they are widely used in mechanical transmission and the whole mechanical field. There are many types of gears, mainly reclusive gear axis classification, generally divided into parallel shaft, intersecting shaft and staggered shaft three types.view

How Many Types of Gears Are There? What Common Materials Are Suitable for Making Gears?October 26, 2023Gears are mechanical parts with teeth that can mesh with each other, and they are widely used in mechanical transmission and the whole mechanical field. There are many types of gears, mainly reclusive gear axis classification, generally divided into parallel shaft, intersecting shaft and staggered shaft three types.view Fasteners 101: Common Types of Automotive FastenersAugust 24, 2023Automotive fasteners are an essential component in the construction and maintenance of vehicles. As a result, automotive part manufacturing relies on high-tolerance designs that include connecting mec...view

Fasteners 101: Common Types of Automotive FastenersAugust 24, 2023Automotive fasteners are an essential component in the construction and maintenance of vehicles. As a result, automotive part manufacturing relies on high-tolerance designs that include connecting mec...view What is a CNC Lathe? Definitions, Uses, Types & BenefitsMarch 29, 2024This article provides a comprehensive introduction to CNC lathes, including their types, applications, benefits, and more. Read on and get detailed information.view

What is a CNC Lathe? Definitions, Uses, Types & BenefitsMarch 29, 2024This article provides a comprehensive introduction to CNC lathes, including their types, applications, benefits, and more. Read on and get detailed information.view What Are the Types of Metal Surface Finish?September 16, 2022Machining surface finishing is an important processing procedure in machining. Machining surface finish can play an important role in protecting and beautifying the workpiece. In machining, there are ...view

What Are the Types of Metal Surface Finish?September 16, 2022Machining surface finishing is an important processing procedure in machining. Machining surface finish can play an important role in protecting and beautifying the workpiece. In machining, there are ...view Metal Milling Techniques and ApplicationsNovember 3, 2023Are you fascinated by the art of shaping metal into precision components or intricate designs? In this comprehensive guide, I'll walk you through the world of metal milling, from the fundamental concepts to advanced applications.view

Metal Milling Techniques and ApplicationsNovember 3, 2023Are you fascinated by the art of shaping metal into precision components or intricate designs? In this comprehensive guide, I'll walk you through the world of metal milling, from the fundamental concepts to advanced applications.view

EN

EN

ru

ru