The manufacturing process of a part does not end with fabrication; it goes through additional steps before it can be used. One of these steps is deburring, crucial for finishing fabricated components in prototyping manufacturing. Deburring not only enhances the visual appeal but also ensures the safety, durability, and proper fit of the parts. In this article, we will explore deburring meaning, discussing importance, and process. Let's begin by answering the question: "What is deburring?"

Deburring is the process of removing burrs, which are small imperfections or rough edges that remain on a workpiece after machining or fabrication. Burrs are commonly found in various machining processes and can greatly influence the quality of the final part. It is essential to understand a clear definition of what burrs are and understand why we need deburring.

1. Rollover Burrs

These are curled-up fragments of material that protrude from the part's surface. They occur when a cutting tool exits the material and are the most common type of burrs.

2. Breakout Burrs

These burrs appear as if they are bulging out from the workpiece. They form due to the force exerted on the workpiece by the machining equipment.

3. Poison Burrs

Poison burrs develop when excess material gathers at the end of the workpiece, often caused by a cutting tool exceeding the workpiece's boundaries. They manifest as small metal fragments extending sideways from the workpiece.

Enhanced Part Safety

Burrs with sharp edges pose a safety risk to individuals handling the components. Deburring eliminates these hazards, promoting a safer work environment and reducing the chance of accidental injuries.

Streamlined Component Assembly

Burrs can hinder the proper fit of parts during assembly, resulting in interference and difficulties in achieving precise fits. Deburring ensures components fit correctly, simplifying the assembly process and ensuring proper functionality.

Increased Durability and Resistance to Wear

Burr on the surface of a part can create excessive friction, leading to increased wear and potential fatigue. Deburring reduces the risk of wear, improving the longevity and reliability of the components.

Burrs can be caused by various factors in both the machining and cutting processes:

Tool Geometry and Condition

Inappropriate tool geometry or a dull cutting tool can lead to burr formation during machining.

Cutting Parameters

Incorrect cutting speed, feed rate, or depth of cut can result in burr formation.

Material Properties

Certain materials, especially those that are hard or prone to chip formation, are more likely to produce burrs during machining.

Tool Vibration or Deflection

Excessive tool vibration or deflection can cause uneven cutting forces and contribute to burr formation.

Die or Blade Condition

Wear or damage to dies or blades can result in burrs during the cutting process.

Clearances

Insufficient clearance between the cutting tool and the workpiece can lead to burr formation.

Cutting Speed and Pressure

Poor control of cutting speed or excessive cutting pressure can cause burrs during cutting operations.

Deburring can be performed on metal and various types of materials using different methods. Here are some common approaches for deburring:

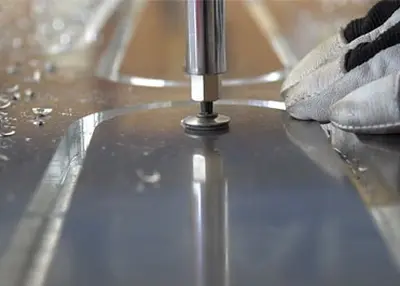

1. Manual Deburring

For smaller components or delicate materials, manual deburring using hand tools like files, abrasive pads, or deburring knives can be employed. This allows for precise control over burr removal.

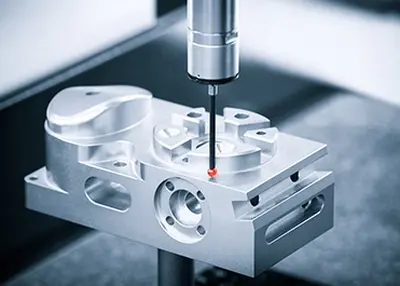

2. Mechanical Deburring

Mechanical methods involve the use of machines or equipment to deburr edges from metal and material surfaces. This can include processes such as grinding, sanding, or using abrasive wheels, belts, or discs to smooth out rough edges.

3. Tumbling

Tumbling is a batch processing method where the metal or material components are placed inside a rotating drum or container with abrasive media. As the drum rotates, the abrasive media removes burrs and polishes the surfaces.

4. Vibratory Deburring

Similar to tumbling, vibratory deburring utilizes a vibrating container or bowl along with abrasive media to remove burrs. The vibrations and friction between the media and workpieces help to smooth out the surfaces.

5. Thermal Deburring

Thermal deburring, also known as TEM or explosion deburring, involves exposing the workpiece to a high-temperature gas mixture or energy source. The rapid heat expansion causes the burrs to break and be removed from the surface.

6. Chemical Deburring

Chemical deburring utilizes specially formulated acids, electrolytes, or chemical solutions to selectively dissolve burrs from the metal or material surface. This method is effective for complex shapes or hard-to-reach areas.

When it comes to finding a machining company that can effectively bring your parts production to life, Richconn is an excellent choice.

1. High-Quality Machining

Richconn provides high-quality machining services, ensuring that your products are manufactured to meet your specific requirements. We have expertise in precision machining and utilize advanced equipment to deliver exceptional results.

2. Burr Removal

Richconn understands the importance of eliminating burrs for a professional finish. We have specialized processes and techniques in place to ensure that your parts are free from burrs, achieving the desired appearance and functionality.

3. Comprehensive Solutions

Richconn offers comprehensive solutions from prototyping to mass production. We can accommodate various tolerances, material preferences, and surface finishing, providing flexibility and meeting your production needs. Our teams are committed to delivering on time and within the agreed-upon lead time.

Deburring is an important step in achieving smooth and high-quality parts during the manufacturing process. By choosing the right deburring method, we can remove burrs effectively without causing harm to the parts or wasting time and money. Contact us today with your project details, and let us support you in achieving the right finish for your parts. We look forward to the opportunity to exceed your expectations and provide you with exceptional service.

6 Benefits of Partnering With a Trusted CNC CompanySeptember 13, 2023Why choose a CNC company to partner with? Let’s explore the advantages of partnering with a CNC company for precision machining and top-quality parts.view

6 Benefits of Partnering With a Trusted CNC CompanySeptember 13, 2023Why choose a CNC company to partner with? Let’s explore the advantages of partnering with a CNC company for precision machining and top-quality parts.view CNC numerical control cutting aluminum sheet, the efficient tool of modern manufacturingAugust 4, 2023In modern manufacturing, aluminum sheets are widely used, and CNC (Computer Numerical Control) cutting technology has become an efficient tool for processing aluminum sheets. CNC cutting aluminum she...view

CNC numerical control cutting aluminum sheet, the efficient tool of modern manufacturingAugust 4, 2023In modern manufacturing, aluminum sheets are widely used, and CNC (Computer Numerical Control) cutting technology has become an efficient tool for processing aluminum sheets. CNC cutting aluminum she...view How Online 3D Printing Revolutionizes Design and Production?August 15, 2023The world of manufacturing has undergone a remarkable transformation with the advent of online 3D printing. This innovative technology has revolutionized how we bring ideas to life, offering a conveni...view

How Online 3D Printing Revolutionizes Design and Production?August 15, 2023The world of manufacturing has undergone a remarkable transformation with the advent of online 3D printing. This innovative technology has revolutionized how we bring ideas to life, offering a conveni...view CNC Machining Aerospace Parts: The Manufacturing Key to High-precision EngineeringSeptember 22, 2023As an avid fan of aerospace technology, I'm excited to take you into the world of CNC machining of aerospace parts, where precision meets innovation.view

CNC Machining Aerospace Parts: The Manufacturing Key to High-precision EngineeringSeptember 22, 2023As an avid fan of aerospace technology, I'm excited to take you into the world of CNC machining of aerospace parts, where precision meets innovation.view Ultra-High Precision Laser Cutting Technology: A Detailed Explanation of Its Technology and ApplicationsJanuary 3, 2024We delve into the intricacies of ultra-high-precision laser cutting, exploring its technology, applications, benefits and challenges.view

Ultra-High Precision Laser Cutting Technology: A Detailed Explanation of Its Technology and ApplicationsJanuary 3, 2024We delve into the intricacies of ultra-high-precision laser cutting, exploring its technology, applications, benefits and challenges.view The Beginner's Guide to the 3D Printing ProcessMay 5, 2024This article explains what 3D printing is, the materials it uses, its advantages, processes and techniques, applications, and more. Read on and get the best custom 3D printing services.view

The Beginner's Guide to the 3D Printing ProcessMay 5, 2024This article explains what 3D printing is, the materials it uses, its advantages, processes and techniques, applications, and more. Read on and get the best custom 3D printing services.view

EN

EN

ru

ru