Manufacturing technologies are continually evolving, opening up new opportunities for manufacturers throughout the entire life cycle. More and more product developers are choosing to switch from one production process to another or switch between processes as needed.

Parts and products usually go through three phases during development: After the prototype has been manufactured, it is first manufactured in small series before finally going into series production. The aim is to achieve a seamless transition between the development phases while the product and its feasibility are further optimized. The ultimate goal is to efficiently minimize the time and costs of the entire process from conception to series production. Fast 3D prints is often ideal for producing plastic parts quickly, flexibly and cost-effectively. However, what is the next step when you want to put your product development plan into action? Injection molding is often a good choice, but not every project is suitable for every manufacturing method. Whether the process is suitable for your product depends on various factors:

The cost of a part is determined by numerous criteria. When it comes to injection molded parts, a significant amount goes into the production of the tools. Injection molding involves injecting molten plastic into the negative cavity of a tool, also known as a mold. If tool production is a large investment, an economical part price can only be achieved by mass producing several hundred or thousand pieces. Other factors include the manufacturing time per part and the number of pieces required. Whether the injection molding process is economical may ultimately depend on whether the number of pieces required justifies the tooling costs.

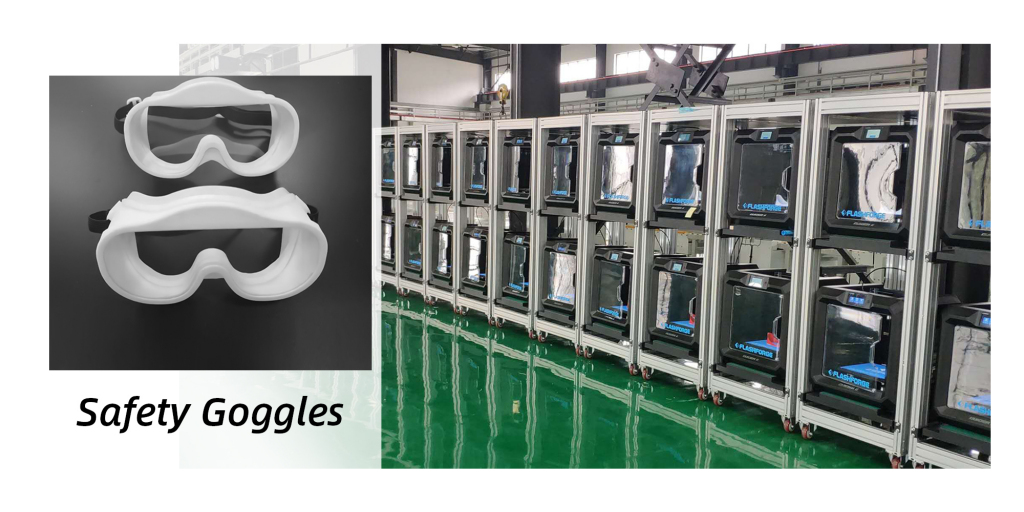

At Richconn, we have managed to reduce costs and time through numerous process optimizations. It typically only takes 1 to 15 days to make your tool. This is an excellent option for batch sizes ranging from a few hundred to 150,000 parts. Our solution is often used for the individualized series production of parts when the product needs to be adapted to different market segments. With 3D printing, there is no need to make a tool beforehand. Your part will be printed directly and you can use it to create almost any design. This makes sense especially if you only need a few hundred parts or parts in several versions.

The better the design, the lower the production costs can be. In-depth knowledge of the manufacturing process is therefore extremely important when producing prototypes. For simple components with a relatively simple geometry, the injection molding process is usually the most cost-effective for a corresponding number of units. However, for complex geometries, 3D printing is the better option.

The surface quality is also crucial for the choice of production method. In 3D printing, parts are built layer by layer, so the finished surface can be angular. Although it can be subsequently smoothed using vapor smoothing, the post-processing step must be taken into account during planning. Parts produced using injection molding have a smooth surface because the material is introduced into the mold in a single pass.

The choice of material is a crucial factor. It not only affects the cost, but also the features and lifespan of your product. Each production process is suitable for certain types of materials, although the choice is greater for injection molding than for 3D printing.

At Richconn we offer hundreds of different resins for the production of injection molded parts, while for 3D printing you can choose from 14 types as standard. Of course, you can also order special materials for both processes. However, this involves additional effort, which you should take into account when planning.

Spray painting, powder spraying, electrophoresis: three common surface treatment methodsMarch 6, 2024Spray painting is a common way of surface treatment, its principle is to use air pressure to spray paint from the nozzle, forming tiny droplets, that and evenly attached to the surface of the painted object.view

Spray painting, powder spraying, electrophoresis: three common surface treatment methodsMarch 6, 2024Spray painting is a common way of surface treatment, its principle is to use air pressure to spray paint from the nozzle, forming tiny droplets, that and evenly attached to the surface of the painted object.view The Application of CNC Machining in Mechanical Equipment - SheetMay 7, 2024Let’s explore the world of sheet in mechanical equipment! Read this article to discover its importance, applications, manufacturing processes, and more.view

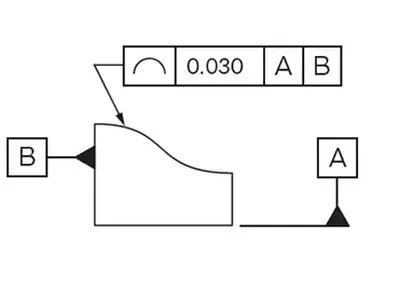

The Application of CNC Machining in Mechanical Equipment - SheetMay 7, 2024Let’s explore the world of sheet in mechanical equipment! Read this article to discover its importance, applications, manufacturing processes, and more.view Unveiling the Precision: The Line Profile UnraveledNovember 21, 2023In the vast realm of engineering and manufacturing, the significance of line profiles cannot be overstated. These seemingly simple geometric elements play a pivotal role in ensuring precision, guiding us through the intricacies of design and production.view

Unveiling the Precision: The Line Profile UnraveledNovember 21, 2023In the vast realm of engineering and manufacturing, the significance of line profiles cannot be overstated. These seemingly simple geometric elements play a pivotal role in ensuring precision, guiding us through the intricacies of design and production.view A Basic Introduction to CNC LathesJune 11, 2024If you're eager to delve into the captivating realm of CNC lathes, this article is your gateway. Whether you're interested in their specific functionalities, wide-ranging applications, or significant roles in the manufacturing industry, this is the perfect read to quench your curiosity.view

A Basic Introduction to CNC LathesJune 11, 2024If you're eager to delve into the captivating realm of CNC lathes, this article is your gateway. Whether you're interested in their specific functionalities, wide-ranging applications, or significant roles in the manufacturing industry, this is the perfect read to quench your curiosity.view The Creative Masters' Secret Weapon: The Process and Application of Two-Tone ElectroplatingAugust 1, 2023Two-tone electroplating is a common surface treatment process we see, used on many products or parts. Want to understand how to achieve two-tone electroplating? This article introduces this unique par...view

The Creative Masters' Secret Weapon: The Process and Application of Two-Tone ElectroplatingAugust 1, 2023Two-tone electroplating is a common surface treatment process we see, used on many products or parts. Want to understand how to achieve two-tone electroplating? This article introduces this unique par...view What Does Color Flaw Detection Mean?October 19, 2023Color flaw detection is a method of non-destructive testing, it is a surface inspection method, mainly used to detect such as the naked eye can not identify the cracks and other surface damage, such as the detection of stainless steel material near the surface defects (cracks), porosity, porosity, delamination, unwelded and unfused and other defects (also known as PT detection).view

What Does Color Flaw Detection Mean?October 19, 2023Color flaw detection is a method of non-destructive testing, it is a surface inspection method, mainly used to detect such as the naked eye can not identify the cracks and other surface damage, such as the detection of stainless steel material near the surface defects (cracks), porosity, porosity, delamination, unwelded and unfused and other defects (also known as PT detection).view

EN

EN

ru

ru