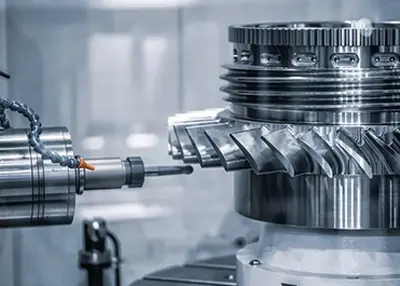

In the ever-evolving world of manufacturing, CNC machining has emerged as a game-changer. This revolutionary technology has enabled businesses to enhance productivity, reduce errors, and improve precision in their production processes. However, one aspect that often gets overlooked is the choice of materials for CNC projects. While high-quality materials may seem like the obvious choice, opting for cheap CNC material can offer significant advantages for cost-conscious entrepreneurs. In this blog post, we will explore how you can optimize your CNC projects with affordable materials and still achieve exceptional results.

When it comes to CNC machining, the material you choose for your project can make all the difference. High-quality materials may offer superior strength and durability, but they often come with a hefty price tag. However, it's crucial to remember that many projects don't necessarily require extravagant materials. By carefully assessing the requirements of your specific project and understanding the limitations of cheap CNC materials, you can strike the perfect balance between cost-effectiveness and functionality.

Opting for cheap CNC materials can bring several advantages to your projects. Firstly, it significantly reduces production costs, allowing you to allocate your budget to other essential areas. Moreover, cheap materials are often more readily available, ensuring a quicker turnaround time for your CNC projects. Additionally, using affordable materials allows for greater experimentation and prototyping, enabling you to test multiple iterations without breaking the bank.

Finding cheap CNC materials doesn't mean compromising on quality. In fact, there are various reliable sources from where you can obtain cost-effective materials. Online marketplaces and bulk material suppliers are great places to start your search. By comparing prices, negotiating deals, and building relationships with suppliers, you can consistently acquire materials that meet your budgetary requirements without sacrificing quality.

To ensure optimal results with cheap CNC materials, it's essential to follow certain strategies. Firstly, invest in a well-calibrated CNC machine that can handle a wide variety of materials. This versatility will allow you to work with inexpensive materials without compromising precision. Secondly, optimize your cutting parameters to suit the specific characteristics of the chosen material. Adjusting spindle speed, feed rate, and cutting depth can help mitigate any limitations of cheap materials, ensuring accurate and high-quality results. Finally, consistently monitor and maintain your CNC machine to minimize wear and tear caused by working with less expensive materials.

By considering cheap CNC materials as a viable option for your projects, you can optimize your manufacturing processes and achieve significant cost savings. Carefully selecting affordable materials that meet the requirements of your project, sourcing from reliable suppliers, and implementing efficiency-maximizing strategies will help you strike the perfect balance between quality and affordability. Embrace the power of smart savings, and you'll discover new possibilities in the world of CNC machining.

Achieve Stunning Automotive Finishes with CNC Powder CoatingFebruary 29, 2024In the world of automotive customization, achieving a flawless and long-lasting finish is essential. Whether you are a car enthusiast looking to give your vehicle a new look or a professional in the i...view

Achieve Stunning Automotive Finishes with CNC Powder CoatingFebruary 29, 2024In the world of automotive customization, achieving a flawless and long-lasting finish is essential. Whether you are a car enthusiast looking to give your vehicle a new look or a professional in the i...view What Is Passivation and How to Passivate Stainless SteelSeptember 26, 2023Passivation is a technique used in cnc machining services for the surface treatment of metals to improve their corrosion resistance, extend their service life, and enhance their appearance.view

What Is Passivation and How to Passivate Stainless SteelSeptember 26, 2023Passivation is a technique used in cnc machining services for the surface treatment of metals to improve their corrosion resistance, extend their service life, and enhance their appearance.view Machined Bearings Basics and Working PrinciplesNovember 9, 2023Welcome to the world of Machined Bearings, where precision engineering meets mechanical efficiency. If you're here, you're probably as curious as I was when I first delved into this field. You're in for a treat because we've crafted a comprehensive guide to take you on a journey through Machined Bearings, from the basics to advanced applications.view

Machined Bearings Basics and Working PrinciplesNovember 9, 2023Welcome to the world of Machined Bearings, where precision engineering meets mechanical efficiency. If you're here, you're probably as curious as I was when I first delved into this field. You're in for a treat because we've crafted a comprehensive guide to take you on a journey through Machined Bearings, from the basics to advanced applications.view CNC POR: Demystifying the Key Technology in CNC MachiningNovember 2, 2023In the world of precision engineering and manufacturing, CNC technology plays a pivotal role. Among the various CNC techniques, CNC POR stands out as a critical component, offering unmatched precision, efficiency, and versatility.view

CNC POR: Demystifying the Key Technology in CNC MachiningNovember 2, 2023In the world of precision engineering and manufacturing, CNC technology plays a pivotal role. Among the various CNC techniques, CNC POR stands out as a critical component, offering unmatched precision, efficiency, and versatility.view Micron-level machining accuracy 2024: Discover the endless possibilities of ultra-high-precision laser cutting processesJanuary 8, 2024Micron-level processing precision is increasingly widely used in various fields, especially in high-end manufacturing industries such as aerospace, electronic products, and medical equipment.view

Micron-level machining accuracy 2024: Discover the endless possibilities of ultra-high-precision laser cutting processesJanuary 8, 2024Micron-level processing precision is increasingly widely used in various fields, especially in high-end manufacturing industries such as aerospace, electronic products, and medical equipment.view Importance Of CNC Machining In Manufacturing Different PartsOctober 24, 2023CNC machining services help you to manufacture and fabricate different parts of metal as per the requirements. This process also helps in creating tolerances for various materials and metal parts. This process is usually a subtractive method of producing metal parts.view

Importance Of CNC Machining In Manufacturing Different PartsOctober 24, 2023CNC machining services help you to manufacture and fabricate different parts of metal as per the requirements. This process also helps in creating tolerances for various materials and metal parts. This process is usually a subtractive method of producing metal parts.view

EN

EN

ru

ru