Five-axis machining centers have long been important in the aerospace industry, where machined parts follow the aerodynamic form of the aircraft. Some machines move the rotary axis simply to position the tool or work outside of the cut. Machines capable of this "3+2" machining can often achieve all the machined features of a part in a single setup.

Five-axis machining is the addition of two rotary axes to the three common linear axes of X, Y and Z. The two rotary axes of the three axes (A,B,C) have different movements to meet the technical requirements of various products.

The five axes of a 5-axis machining center usually refers to the ability of the CNC machine to move parts or tools in five different CNC axes at the same time. Standard 3-axis milling is performed in the X, Y and Z axes. These three linear axes are the directions in which the spindle or part (depending on the machine) can be moved: X-axis: left to right, Y-axis: front to back, and Z-axis: up and down. Five-axis machining centers also use two rotary axes: A-axis, B-axis and C-axis. A-axis: rotation around the X-axis, B-axis: rotation around the Y-axis and C-axis: rotation around the Z-axis.

The use of rotary axes on a 5-axis machining center means that the machine can move the part or cutting tool (spindle head) around one of the previously established linear axes. Different machining machines will use different combinations of axes (A and B, B and C, A and C), with each configuration suitable for different types of machining.

The 5-axis machining process is also very much like the 3-axis CNC machining process. However, it has some very important features that provide these two additional axes and greater cutting flexibility. In a 5-axis machining center its spindle and tool move along three axes. However, there are other rotations around the X-axis (called the A-axis), Y-axis (called the B-axis) and Z-axis (called the C-axis). Five-axis machining centers can use any two of these axes of rotation, depending on their configuration.

An important advantage of 5-axis machining center is that it can use shorter cutting tools, because the head can be lowered toward the work and the tool toward the surface. As a result, higher cutting speeds can be achieved without placing excessive loads on the tool, thereby extending tool life and reducing breakage. The use of shorter tools also reduces tool vibration that can result when machining deep cores or cavities with a 3-axis machine. This results in a higher quality surface finish, thus reducing or even eliminating the need for time-consuming manual finishing.

Another major benefit of machining with a five-axis machining center is the ability to machine extremely complex parts from solids that would otherwise have to be cast. For prototypes and very small runs, this method is faster and cheaper. It can provide lead times of one to two weeks instead of the two months or more required for castings.

Five-axis machining center machining also saves a lot of drilling time. While this may seem insignificant compared to the difficulty of machining complex cores or cavities, drilling a series of holes with different compound angles is very time consuming. With a three-axis machine, a different setup must be used for each hole. With a 5-axis machining center, the head can be automatically oriented along the correct axis for each hole, allowing drilling to be done much faster.

CNC Machining 101: What Are CNC Machining Services?August 11, 2023CNC machines have become increasingly popular in various industries due to their precision and efficiency. They are manufacturing different parts and fittings in a wide range of industries, such as au...view

CNC Machining 101: What Are CNC Machining Services?August 11, 2023CNC machines have become increasingly popular in various industries due to their precision and efficiency. They are manufacturing different parts and fittings in a wide range of industries, such as au...view Machining outsourcing: advantages and disadvantages of full analysisNovember 16, 2023Machining Outsourcing is a common business model in the manufacturing industry that takes a company's machining needs and gives them to another outside supplier that specializes in machining.view

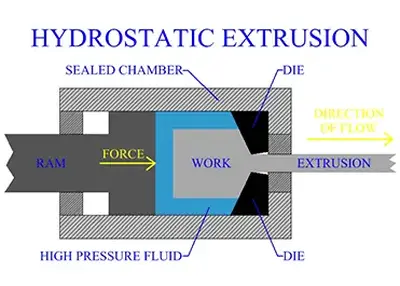

Machining outsourcing: advantages and disadvantages of full analysisNovember 16, 2023Machining Outsourcing is a common business model in the manufacturing industry that takes a company's machining needs and gives them to another outside supplier that specializes in machining.view Extrusion: A Manufacturing Process for Creating Various Shapes and ProductsNovember 30, 2023what is extrusion?Extrusion is a process of forcing a material through a die or a nozzle to create a continuous shape or product. The material can be solid, liquid, or semi-solid, and it can be metal,...view

Extrusion: A Manufacturing Process for Creating Various Shapes and ProductsNovember 30, 2023what is extrusion?Extrusion is a process of forcing a material through a die or a nozzle to create a continuous shape or product. The material can be solid, liquid, or semi-solid, and it can be metal,...view The Glass Transition Temperature of PolymersOctober 17, 2023When designing parts for plastic injection molding, there is an important but often overlooked material consideration. It involves the glass transition temperature, or Tg. We'll get into the underlying science later, but for now, keep in mind that there is a temperature at which amorphous materials transition from a glassy/rigid state to a leathery/rubbery state.view

The Glass Transition Temperature of PolymersOctober 17, 2023When designing parts for plastic injection molding, there is an important but often overlooked material consideration. It involves the glass transition temperature, or Tg. We'll get into the underlying science later, but for now, keep in mind that there is a temperature at which amorphous materials transition from a glassy/rigid state to a leathery/rubbery state.view Sheet Metal Thickness Conversion Chart: Galvanized Steel, Stainless Steel, AluminumDecember 5, 2023In sheet metal work, the term "gauge" is frequently employed to specify thickness. Gauges are the units used to indicate the thickness of a metal sheet.view

Sheet Metal Thickness Conversion Chart: Galvanized Steel, Stainless Steel, AluminumDecember 5, 2023In sheet metal work, the term "gauge" is frequently employed to specify thickness. Gauges are the units used to indicate the thickness of a metal sheet.view Material Comparison: Difference between High Speed Steel and Tungsten SteelOctober 31, 2023Materials play a vital role in modern industry, and in the field of precision manufacturing, both high-speed steel and tungsten steel are highly regarded materials. They have an important position in the field of tool, mold and mechanical parts manufacturing, etc. However, there are obvious differences between them in terms of characteristics, features, application areas, etc. In this article, we will introduce and compare them. This article will be introduced and compared.view

Material Comparison: Difference between High Speed Steel and Tungsten SteelOctober 31, 2023Materials play a vital role in modern industry, and in the field of precision manufacturing, both high-speed steel and tungsten steel are highly regarded materials. They have an important position in the field of tool, mold and mechanical parts manufacturing, etc. However, there are obvious differences between them in terms of characteristics, features, application areas, etc. In this article, we will introduce and compare them. This article will be introduced and compared.view

EN

EN

ru

ru