Gears are mechanical parts with teeth that can mesh with each other, and they are widely used in mechanical transmission and the whole mechanical field. There are many types of gears, mainly reclusive gear axis classification, generally divided into parallel shaft, intersecting shaft and staggered shaft three types.

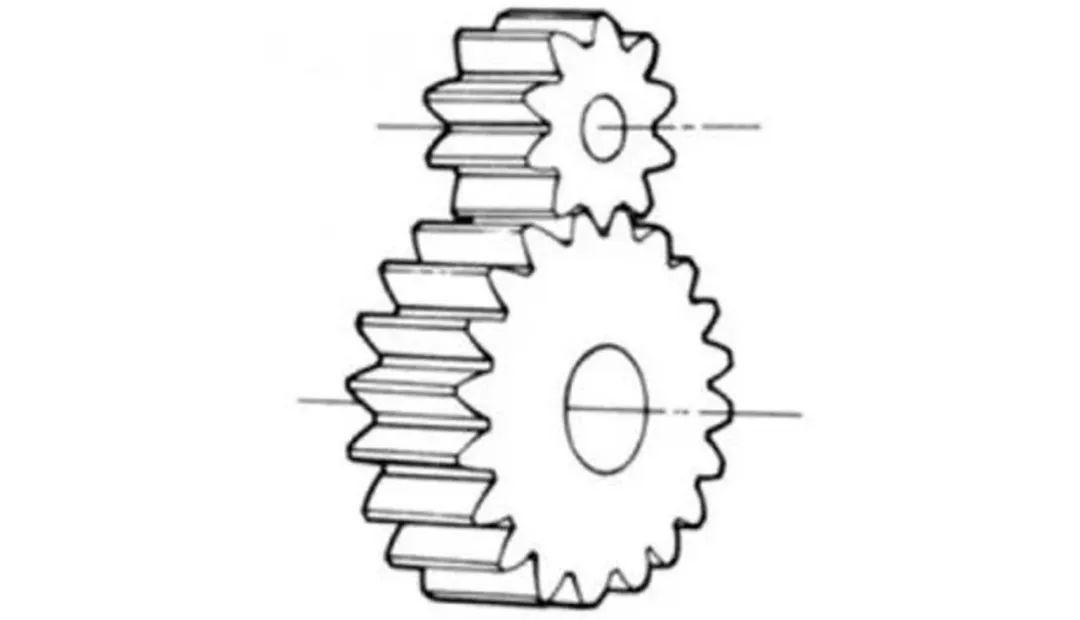

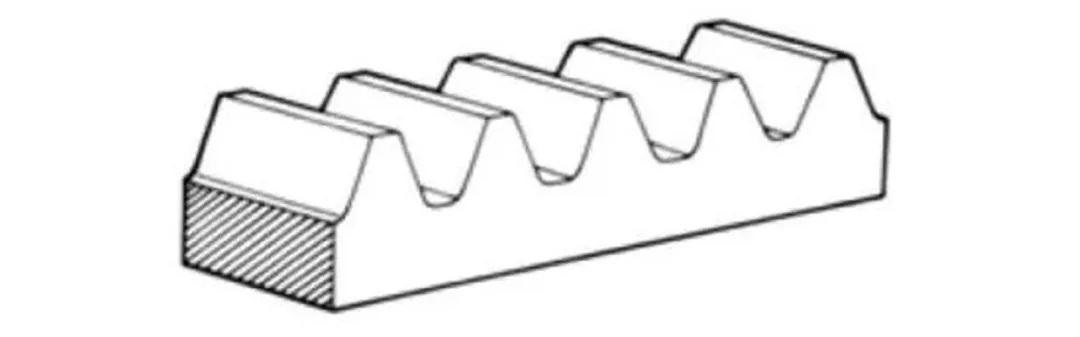

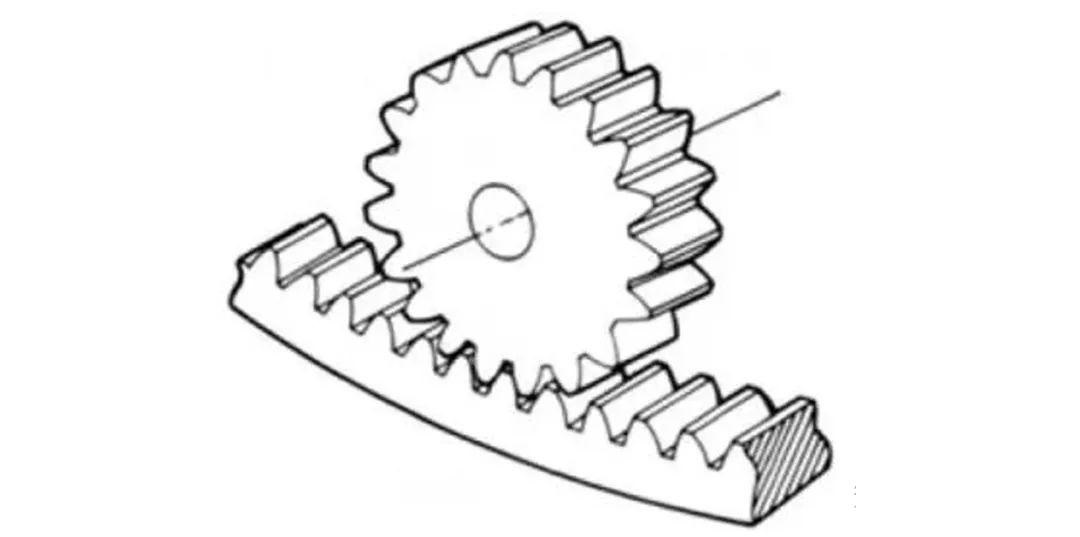

Parallel axis gears: including spur gears, helical gears, internal gears, racks and helical racks.

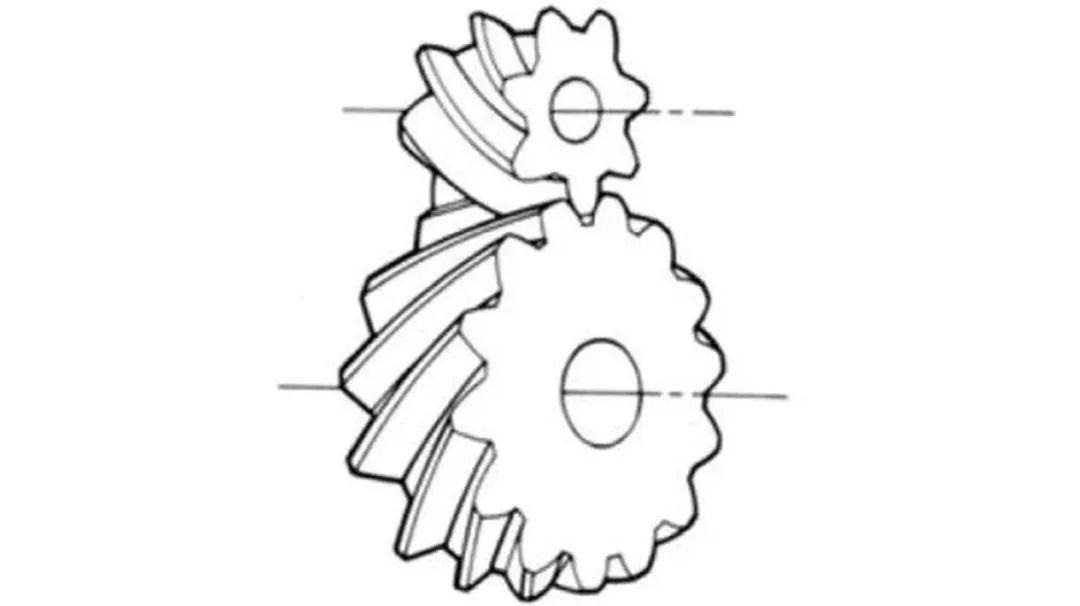

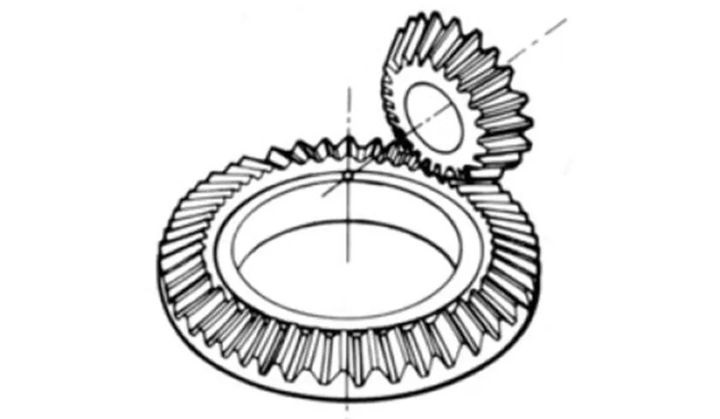

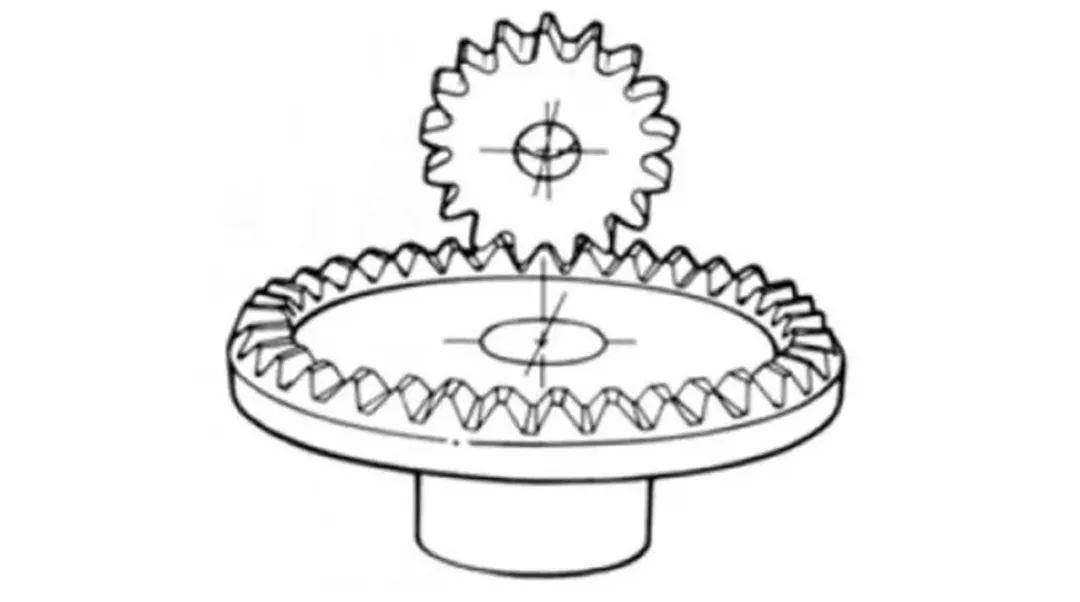

Intersecting axis gears: straight-toothed bevel gears, curved-toothed bevel gears, zero-toothed bevel gears and so on.

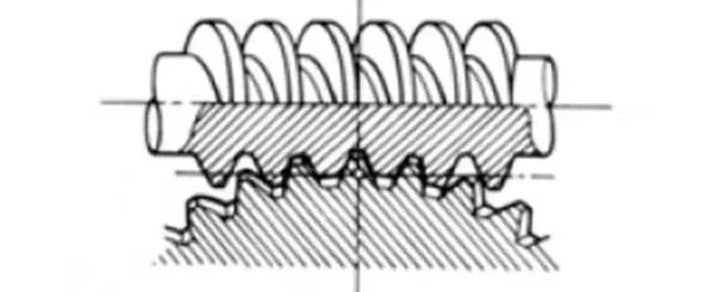

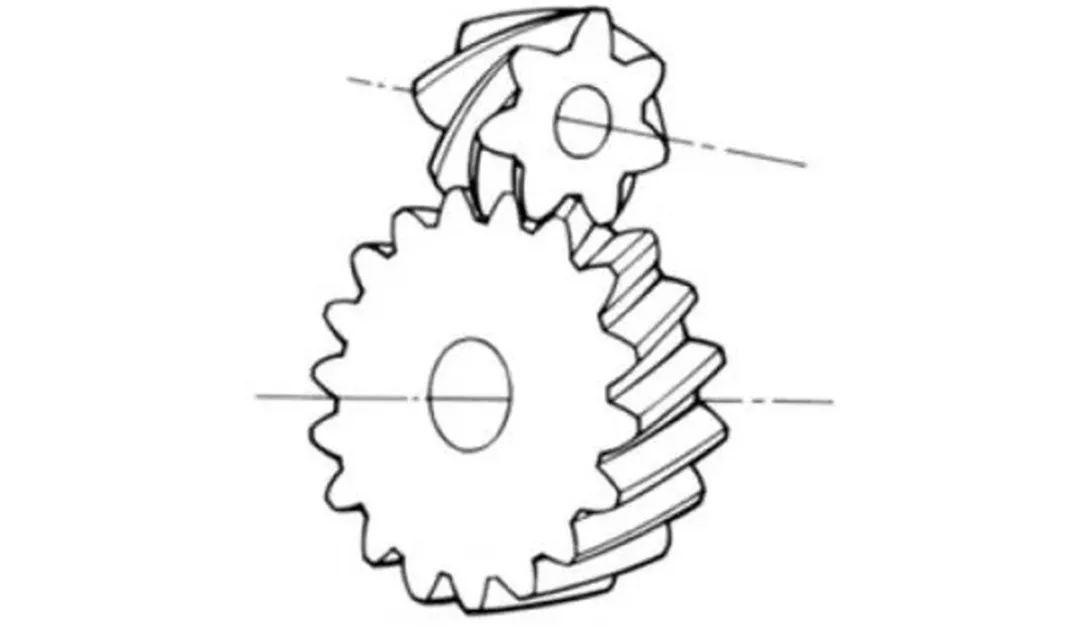

Staggered-axis gears: staggered-axis helical gears, worm gears, hypoid gears and so on.

The meshing of parallel shaft and intersecting shaft gear pair is basically rolling, and the relative sliding is very tiny, so the efficiency is high. Staggered shaft helical gears and worm gears and other staggered shaft gear pairs, because it is through the relative sliding to produce rotation in order to achieve power transmission, so the impact of friction is very large, compared with other gears transmission efficiency is reduced.

The efficiency of gears is the transmission efficiency of gears under normal assembly conditions. If there is an incorrect installation, especially if the bevel gear is assembled at an incorrect distance resulting in an error in the intersection point of the same cone, its efficiency will drop significantly. The efficiencies listed in the table above are transmission efficiencies and do not include losses in bearings, agitation lubrication, etc.

This is a cylindrical gear whose tooth lines are parallel to the centerline of the shaft. They are most widely used in power transmission because they are easy to process.

This is a linear rack gear that meshes with a spur gear. This is a special case when the pitch circle diameter of the spur gear becomes infinite.

This is a gear with teeth machined on the inside of the ring to mesh with the spur gear. It is mainly used in applications such as planetary gears and gear couplings.

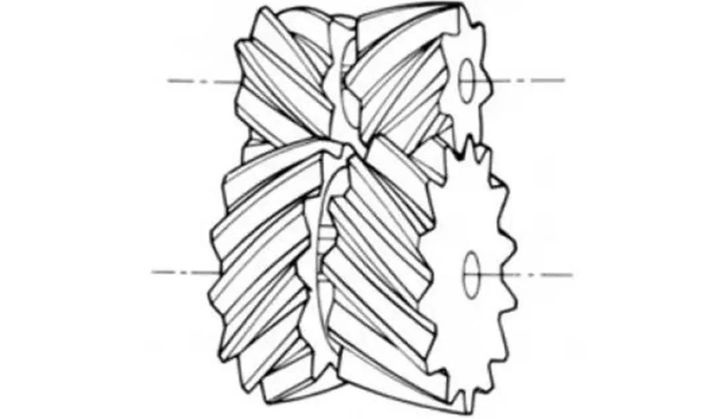

Cylindrical gears with helical tooth lines. They are widely used because they are stronger than spur gears and run smoothly. Generates axial thrust during transmission.

This is a gear in the form of a strip in which a helical rack meshes with a helical gear. This is equivalent to the case when the pitch diameter of the helical gear becomes infinite.

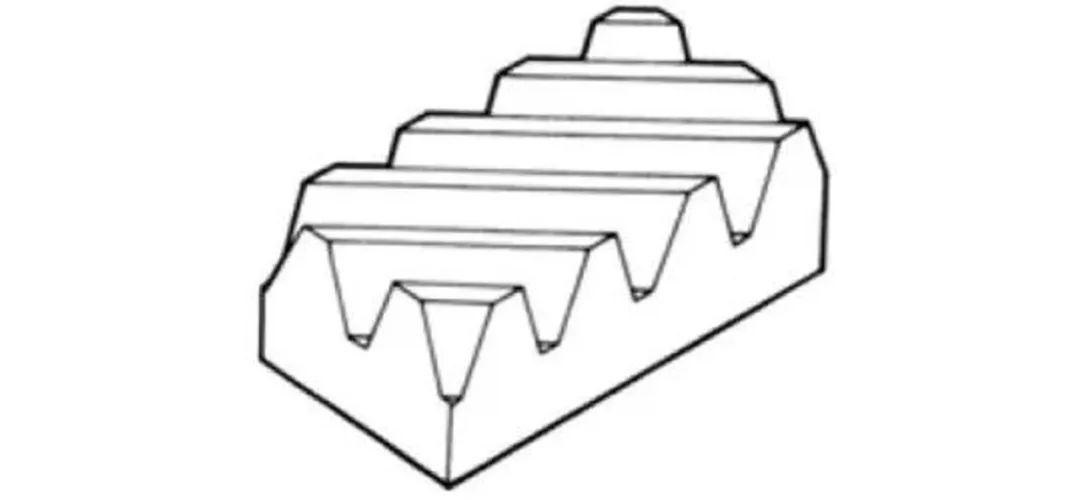

This is a gear made by combining two helical gears with left and right rotating teeth lines. It has the advantage of not generating thrust in the axial direction.

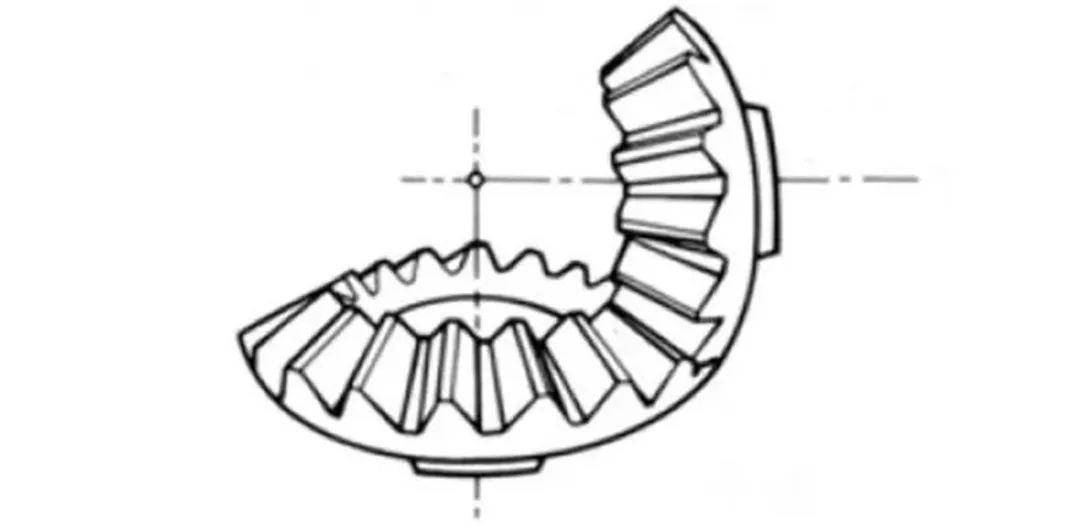

A straight-toothed bevel gear in which the tooth line of the bevel gear is the same as the base line of the pitch cone. Among the bevel gears, it is a type that is easier to manufacture. Therefore, they are widely used as transmission bevel gears.

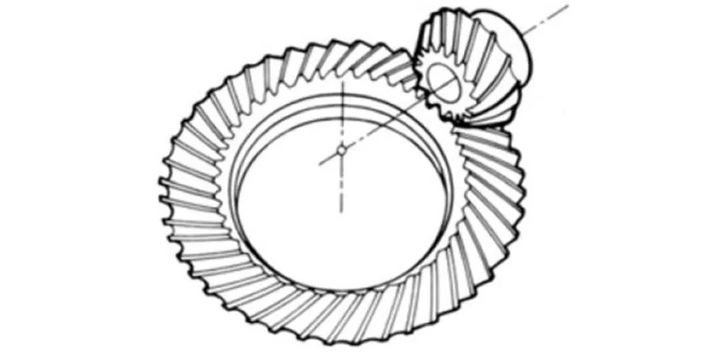

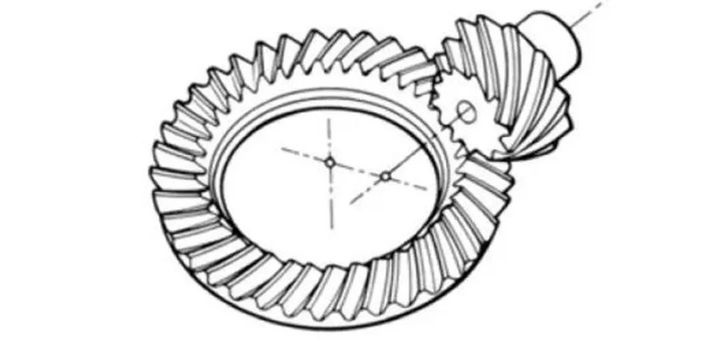

Bevel gears with curved tooth lines and spiral angles. Although it is more difficult to manufacture than straight bevel gears, it is widely used as a high-strength, low-noise gear.

This is a curved-tooth bevel gear with a zero-degree helix angle. Because they have the characteristics of both straight and curved bevel gears, the force on the tooth surface is the same as that of straight bevel gears.

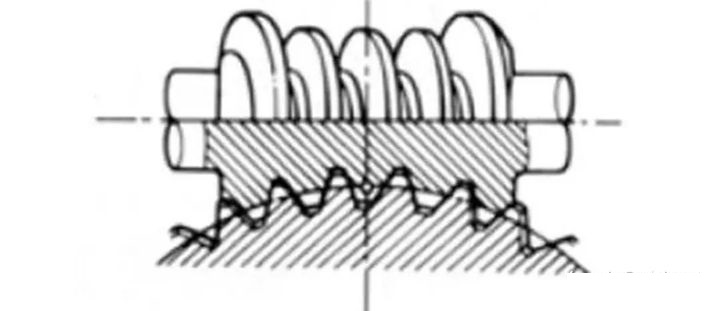

Cylindrical worm gear is the general name of cylindrical worm gear and the worm gear meshing with it. The biggest feature is that it can be operated calmly and can obtain a large transmission ratio by a single pair, but it has the disadvantage of low efficiency.

This is the name of a cylindrical worm gear that is used to drive between staggered shafts. It can be used in the case of helical gears or helical gears and spur gears. The operation is smooth, but it is suitable for use only under light loads.

A disk-shaped gear that meshes with a spur gear or a helical gear. Transmission between straight and staggered shafts.

A general term for a drum worm and the worm gear that meshes with it. Although it is difficult to manufacture, it is possible to drive larger loads than cylindrical worm gears.

A conical gear that is driven between staggered shafts. The large and small gears are processed eccentrically, similar to the arc gears, and the meshing principle is very complex.

The choice of gear material depends mainly on the operating conditions such as load, speed, ambient temperature and lubrication.

Carbon steel is one of the most commonly used materials for gears, it has high strength, good wear resistance and low cost. Mild steel is usually used for low-speed, low-pressure gears, while medium to high carbon steel is used for high-speed, high-load gears. Gears are usually heat-treated (e.g. hardened and tempered) to improve their hardness and wear resistance.

Alloy steels have higher strength and wear resistance than carbon steels and are therefore commonly used to make large, high-load gears. The addition of alloying elements (e.g. chromium, nickel, molybdenum) improves the hardness and toughness of the steel, but also increases the cost of the material.

Cast iron materials such as gray cast iron and ductile iron are also commonly used in gear manufacturing, especially in applications where vibration damping and noise reduction are required. Cast iron has good machinability and relatively low cost, but has low strength and wear resistance.

In corrosive environments, stainless steel may be the gear material of choice. Stainless steel offers good corrosion resistance, but is more costly and generally less hard and strong than carbon and alloy steels.

In some applications, gears may also be manufactured using non-metallic materials such as plastics, nylon, and resins. Non-metallic gears are lightweight, quiet, and do not require lubrication, but their strength, wear resistance, and heat resistance are generally lower.

When selecting gear materials, tradeoffs need to be made based on the gear's operating conditions and performance requirements. For high-speed, high-load gears, it is usually necessary to select materials with high strength and wear resistance; for low-speed, low-load gears, more emphasis may be placed on material cost and processability.

When you need reliable CNC machining services for precision gears, as well as CNC turning services and CNC milling services that support a wide range of materials, Richconn is the place to go. As a precision machine shop based in China, we offer our customers high-quality gear manufacturing solutions with years of experience and expertise.

Gears come in a variety of types, including parallel shaft gears, intersecting shaft gears, and staggered shaft gears. These gear types cover a wide range of mechanical transmission needs. Different types of gears have different characteristics and suitability, with parallel shaft gears being suitable for efficient rolling drives, while staggered shaft gears may be more suitable for light duty applications.

The choice of gear material is critical and has a direct impact on the performance and life of the gear. Commonly used materials for gear manufacturing include carbon steel, alloy steel, cast iron, stainless steel and non-metallic materials. Each material has unique benefits and limitations, and it is important to make a selection based on operating conditions and performance requirements.

Our goal is to provide you with high quality, customized gears to meet your specific needs. Regardless of the type of gear or material you need, Richconn can provide you with the best solution to ensure that your mechanical systems operate at peak efficiency and performance. Choose Richconn for a reliable gear manufacturing partner and work with us to move your project forward!

6 Considerations When Designing Parts For CNCOctober 11, 2023The fact is that when manufacturing parts through on-demand CNC machining, various aspects must be weighed against each other. After all, you wouldn't expect to buy a Bentley for the price of a Mini, but they both basically perform the same function and get us from point A to point B.view

6 Considerations When Designing Parts For CNCOctober 11, 2023The fact is that when manufacturing parts through on-demand CNC machining, various aspects must be weighed against each other. After all, you wouldn't expect to buy a Bentley for the price of a Mini, but they both basically perform the same function and get us from point A to point B.view Anodized Aluminum: How to Anodize Aluminum Parts?January 23, 2024Are you familiar with anodizing aluminum? If not, you can read this article and get to know about the process and other related things.view

Anodized Aluminum: How to Anodize Aluminum Parts?January 23, 2024Are you familiar with anodizing aluminum? If not, you can read this article and get to know about the process and other related things.view 6 Avoidable Mistakes When Designing CNC PartsOctober 13, 2023A common mistake is designing parts with surfaces where material removal would actually be unnecessary. Unnecessary machining contributes to longer machining times, and that greatly impacts the final production cost.view

6 Avoidable Mistakes When Designing CNC PartsOctober 13, 2023A common mistake is designing parts with surfaces where material removal would actually be unnecessary. Unnecessary machining contributes to longer machining times, and that greatly impacts the final production cost.view Some Knowledge You Need to Learn About Design for ManufacturingFebruary 22, 2024Design for Manufacturing (DFM) is a set of best practices that aim to minimize manufacturing errors by focusing on mitigating defects and assessing the quality and dependability of supply chains.view

Some Knowledge You Need to Learn About Design for ManufacturingFebruary 22, 2024Design for Manufacturing (DFM) is a set of best practices that aim to minimize manufacturing errors by focusing on mitigating defects and assessing the quality and dependability of supply chains.view How many types of cast iron are there? How are the grades represented? The various uses of cast iron?October 31, 2023Cast iron is an iron and carbon alloy with carbon content greater than 2.11% (generally 2.5-4%). It is iron, carbon, silicon as the main constituent elements and more than carbon steel contains mangan...view

How many types of cast iron are there? How are the grades represented? The various uses of cast iron?October 31, 2023Cast iron is an iron and carbon alloy with carbon content greater than 2.11% (generally 2.5-4%). It is iron, carbon, silicon as the main constituent elements and more than carbon steel contains mangan...view 304 vs 316 Stainless Steel: Which Is the Right Grade for Your Project?August 24, 2023The comparison between 304 and 316 stainless steel is always the key problem when choosing the right stainless steel grade for your project. Both of these grades belong to the austenitic stainless ste...view

304 vs 316 Stainless Steel: Which Is the Right Grade for Your Project?August 24, 2023The comparison between 304 and 316 stainless steel is always the key problem when choosing the right stainless steel grade for your project. Both of these grades belong to the austenitic stainless ste...view

EN

EN

ru

ru