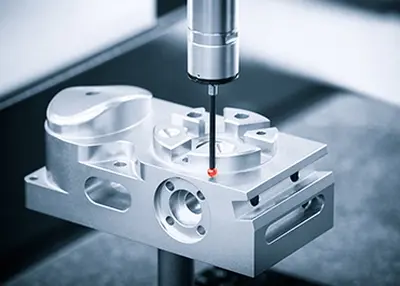

CNC machining is a widely used manufacturing process that involves the use of computer-controlled machines to create precise and complex parts from various materials. CNC machines can operate on different numbers of axes depending on the complexity and flexibility of the desired shape. As industries relentlessly seek to redefine the limits of intricate design and pinpoint accuracy, the incorporation of China's 4-axis CNC machining has ignited a transformative wave. A 4 axis CNC machine takes the art of machining to new heights by integrating an additional rotational axis alongside the standard X, Y, and Z axes.

At its core, the concept of 4 axis CNC machining harnesses the prowess of computer-controlled machinery to navigate along four distinct axes. While the X, Y, and Z axes deliver linear movements, the CNC 4th axis, as known as the A axis, introduces a rotational component. In simpler terms, imagine a machine that can maneuver not only left, right, up, and down, but also rotate in a controlled manner. This crucial A axis rotation usually revolves around the X axis, enabling intricate designs with angled holes, complex slots, and graceful curves to be brought to life.

Either 3 axis or 4 axis CNC machining comes with its set of advantages and limitations, making it essential to understand the distinctions before making a choice that aligns with your project's needs.

3 axis CNC machining, with its focus on linear X, Y, and Z movements, has long been the foundation of manufacturing. It's reliable, cost-effective, and widely adopted across industries. For simpler designs and projects that don't necessitate intricate rotational movement, 3 axis machining can be an ideal choice. Its straightforward programming and setup make it accessible, particularly for those new to CNC machining.

Compared to 3 axis machining, the 4 axis variant takes complexity and precision to the next level. The rotational A axis not only enables the creation of intricate angles and curves but also streamlines the production process for components that require multi-sided machining. However, this added capability comes at the cost of increased complexity in programming and setup, as well as a higher initial investment.

While both variants offer precision, the 4 axis system shines in tasks that demand intricate detailing and multi-sided machining. For instance, a 3 axis machine might struggle to create a perfectly angled hole or carve a complex curve, while a 4 axis machine can execute such tasks with finesse. The ability to manipulate the workpiece in multiple dimensions lends 4 axis machining an upper hand when dealing with intricate designs.

In terms of versatility, 4 axis CNC machining triumphs. It caters to a broader range of industries, from aerospace to jewelry, where intricate designs are the norm. The flexibility to switch between indexed and continuous rotation further enhances its adaptability to different project requirements. The rotational movement unlocks the potential for crafting components that would be a challenge for traditional 3 axis machines.

The adaptability of 4 axis CNC machining is evident in its diverse range of applications across industries:

Aerospace

Precision components with intricate contours and angles are essential in aerospace engineering, making 4 axis machining an indispensable tool for creating aerodynamic parts.

Automotive

The automotive industry leverages the power of 4 axis CNC router machining to manufacture specialized parts that contribute to vehicle performance.

Medical and Dental

From precise medical instruments to intricate dental prosthetics, the medical and dental fields benefit from the precision and complexity offered by 4 axis CNC mill machining.

Jewelry

4 axis CNC machining allows jewelry designers to transform intricate designs into tangible pieces, enhancing their creative possibilities.

As we delve deeper into the realm of 4 axis CNC machining, an intricate tapestry of advantages and considerations emerges.

Reduced Setups and Tool Changes

One of the standout advantages of 4 axis CNC machining lies in its ability to seamlessly integrate the A axis rotation. This ingenious feature minimizes the need for frequent repositioning of the workpiece. With a reduced need for manual intervention, it effectively mitigates downtime.

Precision and Consistency

The A axis rotation in 4 axis CNC machining plays a pivotal role in delivering unparalleled precision. Unlike traditional machining methods, where manually repositioning the workpiece could introduce minor variations, the A axis ensures a continuous and consistent machining process.

Reduced Lead Times

The capability to manufacture complex components within a single setup enhances efficiency. With a reduced need for intermediate handling and repositioning, the production process is streamlined, resulting in significantly reduced lead times.

Expanded Design Horizons with Diverse Geometries

Incorporating the A axis rotation empowers engineers and designers to transcend the limitations of traditional machining. The dynamic movement enabled by the 4th axis CNC offers a canvas for exploring intricate shapes, angles, and geometries.

Higher Initial Investment

The integration of the CNC 4th axis and the associated technology does demand a higher initial investment compared to traditional machining methods. Organizations need to weigh the long-term benefits against the immediate cost implications to ensure a favorable return on investment.

Skill and Expertise Prerequisites for Operation and Maintenance

While 4 axis CNC machining unlocks a world of design innovation, it does require a higher level of expertise for operation and maintenance.

Programming and Setup Complexity

Embracing 4 axis CNC machining introduces a level of programming and setup complexity that might not be encountered in traditional 3 axis machining. The A axis rotation adds an extra layer of sophistication to the process, demanding careful consideration and meticulous planning during the programming phase. This complexity may extend to the setup procedures, potentially requiring additional time and resources to ensure smooth operations.

Richconn, a reputable 4 axis cnc machining manufacturer in the CNC machining arena, presents a compelling alternative to the traditional approach of owning and operating 4th axis CNC machines. With their dedication to research, development, and production of CNC machining parts, they have established themselves as a beacon of innovation and expertise. Their specialization spans across industries such as automotive, electronics, medical, and manufacturing, showcasing their adaptability to diverse manufacturing needs.

Richconn lies in its comprehensive CNC machining services, which encompass an array of machining capabilities, including 3 axis, 4 axis, and 5 axis CNC machines. This means that even if the initial investment in a 4 axis CNC machine seems daunting, you can tap into the expertise and technology leadership that Richconn offers, without committing to the entire setup.

The seamless integration of digital management and a flexible supply chain allows Richconn to offer services that align with your project timelines and specifications. By tapping into their expertise, you can streamline your manufacturing process, achieving efficiency and precision without the complexities of in-house 4 axis CNC machining.

Don't hesitate to get your custom 4 axis CNC machining services NOW↓↓↓

The 4 axis CNC technology with its integration of an additional rotational axis, propels the boundaries of precision, complexity, and efficiency. Looking for the best 4 axis CNC machining services? Why not try us at Richconn? We empower businesses to tap into the benefits of 4th axis CNC machining without the full financial commitment. We help you stand at the intersection of precision and innovation for an unparalleled manufacturing experience!

What is Black Oxide? A Guide on Black Oxide Coating 2023September 5, 2023While there are indeed numerous surface finish types available for manufacturers to choose from, the black oxide coating is a popular choice for many. The black oxide coating offers a combination of v...view

What is Black Oxide? A Guide on Black Oxide Coating 2023September 5, 2023While there are indeed numerous surface finish types available for manufacturers to choose from, the black oxide coating is a popular choice for many. The black oxide coating offers a combination of v...view Common Impact Resistant Plastics.October 17, 2023Tough. Unbreakable. Resistant to punctures and cracks from impact. That's how some people describe impact-resistant plastic. However, as you will see, this term is ambiguous. Just because a piece of chewing gum doesn't break in half when you hit it with a hammer doesn't mean it's impact resistant. Put the same gum in the freezer for a while and then hit it. Only splinters.view

Common Impact Resistant Plastics.October 17, 2023Tough. Unbreakable. Resistant to punctures and cracks from impact. That's how some people describe impact-resistant plastic. However, as you will see, this term is ambiguous. Just because a piece of chewing gum doesn't break in half when you hit it with a hammer doesn't mean it's impact resistant. Put the same gum in the freezer for a while and then hit it. Only splinters.view How to Get a Clear Picture of Quenching, Normalizing, Tempering and Other Material Heat Treatment Issues?October 24, 2023Heat treatment of steel consists of normalizing, annealing, tempering and quenching. Among them, annealing and normalizing are mainly used for preparatory heat treatment, and are only used as final heat treatment when the performance of the workpiece is not required. The purpose of quenching is to obtain martensitic organization and improve the performance of steel.view

How to Get a Clear Picture of Quenching, Normalizing, Tempering and Other Material Heat Treatment Issues?October 24, 2023Heat treatment of steel consists of normalizing, annealing, tempering and quenching. Among them, annealing and normalizing are mainly used for preparatory heat treatment, and are only used as final heat treatment when the performance of the workpiece is not required. The purpose of quenching is to obtain martensitic organization and improve the performance of steel.view One Article Tells You What CNC Machining isSeptember 27, 2023The term CNC stands for "Computer Numerical Control" and CNC machining is defined as a subtractive manufacturing process that typically employs computer-controlled and machine tools to remove layers of material from a stock part (known as a blank or workpiece) and produce a custom-designed part.view

One Article Tells You What CNC Machining isSeptember 27, 2023The term CNC stands for "Computer Numerical Control" and CNC machining is defined as a subtractive manufacturing process that typically employs computer-controlled and machine tools to remove layers of material from a stock part (known as a blank or workpiece) and produce a custom-designed part.view![Chamfer 101: Understanding Chamfers and Chamfered Edge [Quick Guide]](/uploads/image/20231123/14/chamfer-101-understanding-chamfers-and-chamfered-edge-quick-guide_400x400.webp) Chamfer 101: Understanding Chamfers and Chamfered Edge [Quick Guide]November 23, 2023Gain comprehensive knowledge about chamfers, including types, advantages and limitations, various methods of measurement and a comparative feature analysis.view

Chamfer 101: Understanding Chamfers and Chamfered Edge [Quick Guide]November 23, 2023Gain comprehensive knowledge about chamfers, including types, advantages and limitations, various methods of measurement and a comparative feature analysis.view Laser Etching: Guide and Comprehensive ContentOctober 8, 2023Laser Etching is a high-precision processing technique widely used to create fine patterns, markings, and engravings on a variety of materials. It utilizes the high energy of a laser beam to gradually remove the surface of a material to create depth, patterns or text.view

Laser Etching: Guide and Comprehensive ContentOctober 8, 2023Laser Etching is a high-precision processing technique widely used to create fine patterns, markings, and engravings on a variety of materials. It utilizes the high energy of a laser beam to gradually remove the surface of a material to create depth, patterns or text.view

EN

EN

ru

ru