In this comprehensive article, we will delve deep into the mysteries of stainless steel valves, with a particular focus on the working principles and applications of check valves across different industries. If you want to learn about various aspects of stainless steel valves, you definitely don't want to miss out on this insightful content-rich article.

When it comes to industrial equipment and piping systems, stainless steel valves are undoubtedly one of the crucial components. Whether it's chemical, oil, energy, pharmaceutical, or food processing industries, efficient and reliable valves are needed to control fluid flows. In this article, we will take an in-depth look at various questions surrounding stainless steel valves, with a focus on unraveling the mysteries of check valves and their importance in industrial settings.

Stainless steel valves are devices used to control fluid flow, characterized by corrosion resistance and high temperature resistance. They are usually made from AISI 304 or AISI 316L materials, enabling them to work effectively in harsh environments. These valves play a critical role in switching and regulating fluid flows to ensure proper system operation.

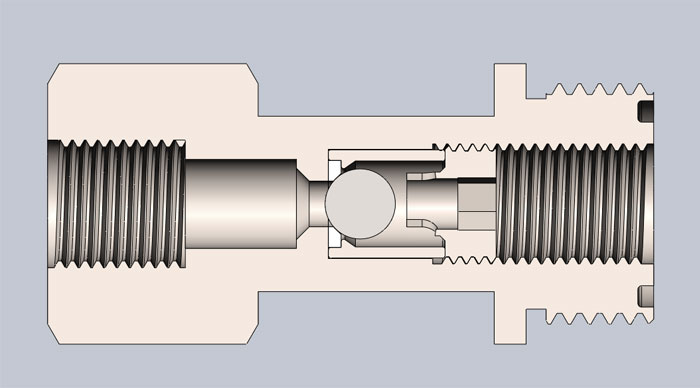

Check valves, also known as non-return valves, are valves that allow fluid flow in one direction but prevent flow in the opposite direction. They work like a door latch, only permitting flow through a passageway in one direction. This is crucial to prevent backflow or reverse flow, especially in applications requiring consistent flow direction.

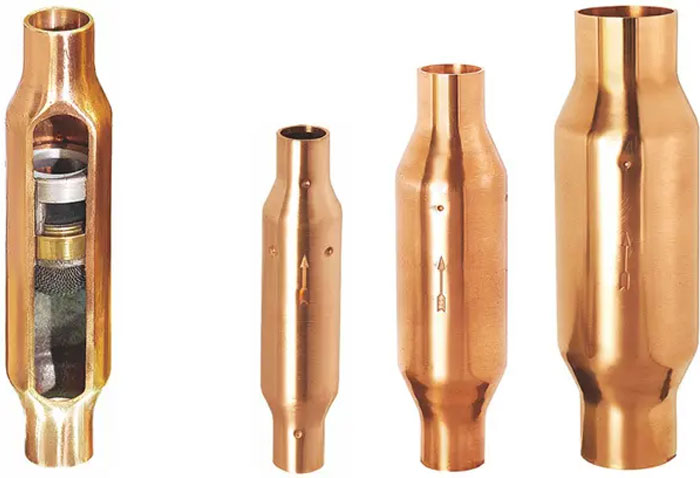

In the world of stainless steel valves, there are various types of check valves, each with unique designs and applications. Here are some common check valve types:

These valves use a moving piston to control fluid flow. The piston lifts when fluid pressure is applied on one side, opening the valve. It drops and closes the valve when pressure reduces or disappears.

Diaphragm check valves use a flexible diaphragm to regulate flow. The diaphragm flexes to allow flow when pressure is applied on one side. But it seals the passage to prevent flow in reverse direction.

Ball check valves have a ball that moves to open the valve when fluid pressure acts. Once the pressure disappears, the ball returns to its original position, closing the valve and preventing backflow.

These valves use a rotating disc to control flow. Their uniqueness lies in the sealing material that effectively prevents leakage.

Stainless steel valves play a crucial role in many fields. Here are some application examples:

In chemical, oil, energy and other industrial applications, stainless steel valves control fluid flows to ensure stable system operation. Their corrosion resistance allows use in harsh chemical environments.

Hygiene is critical in food/beverage processing. Stainless steel valves are favored for their easy cleanability and corrosion resistance to control food and beverage flows.

In pharmaceutical processes, fluid flows must be strictly controlled to ensure drug quality and purity. Stainless steel valves meet these requirements and play an important role.

☑ Prevent backflow. Check valves stop reverse flows in piping networks.

☑ Maintain system pressure. Check valves maintain pressure difference between upstream and downstream for proper flow.

☑ Control flow direction. Check valves are vital for regulating flow direction.

☑ Mitigate water hammer effects. Closing valves can cause water hammer, reduced by check valves.

☑ Water distribution: Prevent backflow of sewage into clean water pipes.

☑ Drainage: Avoid back surge of sewage.

☑ Plumbing: Maintain water pressure.

☑ HVAC: Control medium flow direction.

☑ Hydraulic systems: Keep hydraulic components operational.

☑ Simple structure, no power needed, self-actuated one-way flow.

☑ Fast response, short open and close times.

☑ Compact size, easy installation.

☑ Different sizes suit varying flow rate needs.

☑ Corrosion, high temperature and pressure resistant.

☑ Install in correct position and orientation.

☑ Regularly inspect valve, ensure clack mobility.

☑ Avoid jamming, keep valve passages unobstructed.

☑ Choose valve material compatible with medium.

☑ Design overflow pipes in complex systems to prevent overpressure.

Check valves allow flow in one direction but block reverse flow due to designs like piston in lift checks or diaphragm in diaphragm checks.

Stainless steel valves are suitable for various harsh environments like chemical plants, marine applications due to corrosion and high temperature resistance.

The disc in soft seated butterfly valves uses special sealing materials that intimately conform to the valve seat when rotated, achieving excellent sealing performance.

Yes, regular stainless steel valve maintenance ensures proper working. Lubrication, cleaning and inspection help prolong service life.

Check valves are commonly used in waste water treatment, water supply systems, steam systems etc. to prevent backflow and reverse fluid flows.

Stainless steel valves offer corrosion resistance, high temperature resistance and durability, making them ideal choices for many industrial and commercial applications.

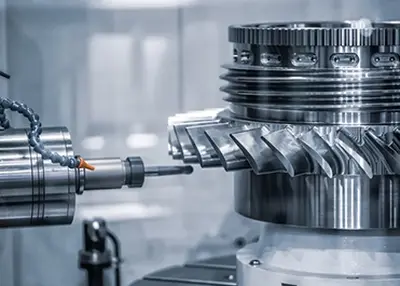

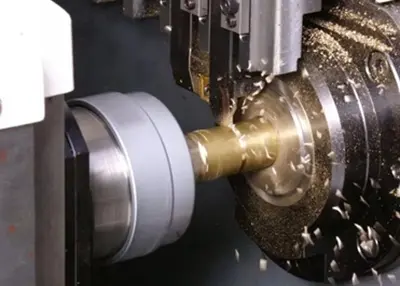

Pro in OEM precision CNC machining, Richconn provides various valve component machining services to many valve companies, capable of OEM manufacturing various valves including but not limited to stainless steel, POM, cast iron valves etc. We have flow, pressure and sealing performance testing capabilities, offering one-stop services. Please contact our sales team to learn more.

Crafting Precision: The Artistry Behind CNC Milling PartsSeptember 22, 2023A CNC milling machine consists of many different parts that each play an important role and work together to accomplish a variety of milling tasks.view

Crafting Precision: The Artistry Behind CNC Milling PartsSeptember 22, 2023A CNC milling machine consists of many different parts that each play an important role and work together to accomplish a variety of milling tasks.view Implant Abutment Materials and SelectionOctober 24, 2023Commonly used implant abutment materials can be divided into five categories: titanium (precision machining, polished, laser etched), surgical grade stainless steel, cast gold alloys, zirconium oxide, and polyether ether ketone (PEEK).view

Implant Abutment Materials and SelectionOctober 24, 2023Commonly used implant abutment materials can be divided into five categories: titanium (precision machining, polished, laser etched), surgical grade stainless steel, cast gold alloys, zirconium oxide, and polyether ether ketone (PEEK).view Unlocking the Infinite Potential of CNC Milling MaterialsFebruary 29, 2024In the intricate tapestry of CNC milling materials, the careful selection of materials emerges as the linchpin, dictating the success and precision of every project.view

Unlocking the Infinite Potential of CNC Milling MaterialsFebruary 29, 2024In the intricate tapestry of CNC milling materials, the careful selection of materials emerges as the linchpin, dictating the success and precision of every project.view Aerospace CNC Machining: A Comprehensive GuideNovember 6, 2023Aerospace CNC machining plays a pivotal role in the aviation and aerospace industry. It's the technology that enables the precision manufacturing of critical components. In this guide, I'll walk you through the importance, applications, key steps, material and process selection, quality standards, and the process of finding a reliable aerospace CNC machining service, with a special recommendation for Richconn's services.view

Aerospace CNC Machining: A Comprehensive GuideNovember 6, 2023Aerospace CNC machining plays a pivotal role in the aviation and aerospace industry. It's the technology that enables the precision manufacturing of critical components. In this guide, I'll walk you through the importance, applications, key steps, material and process selection, quality standards, and the process of finding a reliable aerospace CNC machining service, with a special recommendation for Richconn's services.view What Is CNC Machining?April 4, 2023Definition of CNC MachiningCNC machining refers to the machining process conducted by a control system that controls the tools to perform various movements that meet the technical and processing requi...view

What Is CNC Machining?April 4, 2023Definition of CNC MachiningCNC machining refers to the machining process conducted by a control system that controls the tools to perform various movements that meet the technical and processing requi...view Machining on a Dime: Creating High-Quality Products with Cheap CNC MaterialsDecember 4, 2023In today's fast-paced world, businesses are constantly seeking ways to reduce costs without compromising on quality. This is particularly true for manufacturers who heavily rely on CNC machining t...view

Machining on a Dime: Creating High-Quality Products with Cheap CNC MaterialsDecember 4, 2023In today's fast-paced world, businesses are constantly seeking ways to reduce costs without compromising on quality. This is particularly true for manufacturers who heavily rely on CNC machining t...view

EN

EN

ru

ru