PVD (Physical Vapor Deposition) surface treatment process is usually used to create hard, durable and beautiful surfaces. It involves applying a thin layer of metal or ceramic coating onto an object that has been heated to high temperatures, such as a tool or jewelry. The coating then evaporates and deposits onto the surface of the object, forming a protective layer that makes the product more resistant to wear, corrosion and other types of damage. PVD finish can be used to enhance the appearance and performance of various products, from jewelry and kitchenware to tools, medical devices, and more.

PVD stands for Physical Vapor Deposition, which is a method of depositing thin films of metal or ceramic onto a substrate. This process is used to form a protective layer on the surface of an object, which is then evaporated and deposited onto the surface. The result is a coating that is hard, durable and beautiful.

The advantages of PVD surface treatment include its ability to be used on a variety of materials, including metals, ceramics, and polymers. This makes it an ideal choice for a wide range of applications, including jewelry, medical devices, kitchenware, and other products. Additionally, PVD is a relatively simple and cost-effective process that can produce high-quality results.

PVD surface treatment provides many benefits, including increased durability and improved aesthetics. The coatings are extremely hard, making them ideal for products that experience wear and tear. Additionally, the coatings can be applied in a variety of colors, providing multiple aesthetic choices.

PVD coatings also have high corrosion resistance, making them an ideal choice for products exposed to water or other corrosive elements. Additionally, PVD coatings are very thin, making them less obtrusive and allowing them to be applied to complex designs. Finally, the process is relatively inexpensive and can produce high-quality results.

PVD is used in a variety of applications, including jewellery, medical devices, kitchenware, tools, automotive parts, and more. The process is commonly used to create decorative finishes on jewellery and other products, providing a bright, durable, wear-resistant, and corrosion-resistant coating. Additionally, PVD is often used to create highly durable coatings on tools, medical devices, and automotive parts, improving performance and preventing wear and corrosion.

PVD surface treatment offers a range of advantages, including increased durability and improved aesthetics. The process is relatively simple and cost-effective, making it an ideal choice for various applications, including jewellery, medical devices, kitchenware, tools, and automotive parts. With its hard and corrosion-resistant coatings, PVD helps to extend the life of products and improve their performance.

In addition to PVD, Richconn also specializes in other surface finishing techniques such as electrophoresis finish, which is another popular method for enhancing metal surfaces with improved aesthetics and durability.

As a professional surface finishing supplier, Richconn provides quality PVD coating solutions for customers all over the world. Feel free to contact us at any time!

The Intersection of Chameleon PVD Coating and GadgetsJanuary 5, 2024Innovations in technology have paved the way for stunning advancements in the gadget industry. One such breakthrough that mesmerizes tech enthusiasts is the thrilling use of Chameleon PVD coating. Wit...view

The Intersection of Chameleon PVD Coating and GadgetsJanuary 5, 2024Innovations in technology have paved the way for stunning advancements in the gadget industry. One such breakthrough that mesmerizes tech enthusiasts is the thrilling use of Chameleon PVD coating. Wit...view 6 Reasons Why Choosing a Coastal Processing Supplier Can Make Your Business Better!September 11, 2023If you are an efficient and qualified purchasing staff or boss, you need to read my article, which will break your inherent thinking about supply chain and business management. First, let's think about the following points togetherview

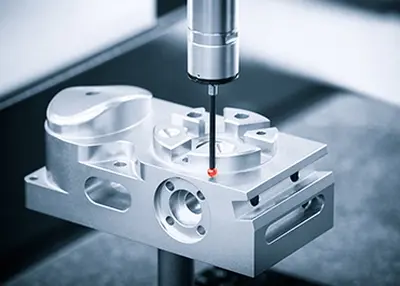

6 Reasons Why Choosing a Coastal Processing Supplier Can Make Your Business Better!September 11, 2023If you are an efficient and qualified purchasing staff or boss, you need to read my article, which will break your inherent thinking about supply chain and business management. First, let's think about the following points togetherview One Article Tells You What CNC Machining isSeptember 27, 2023The term CNC stands for "Computer Numerical Control" and CNC machining is defined as a subtractive manufacturing process that typically employs computer-controlled and machine tools to remove layers of material from a stock part (known as a blank or workpiece) and produce a custom-designed part.view

One Article Tells You What CNC Machining isSeptember 27, 2023The term CNC stands for "Computer Numerical Control" and CNC machining is defined as a subtractive manufacturing process that typically employs computer-controlled and machine tools to remove layers of material from a stock part (known as a blank or workpiece) and produce a custom-designed part.view Electrophoretic Surface Treatment Process Characteristics and Main CharacteristicsSeptember 16, 20221. Characteristics of electrophoresis surface treatment processElectrophoretic paint film has the advantages of full, uniform, flat and smooth coating. The hardness, adhesion, corrosion resistance, im...view

Electrophoretic Surface Treatment Process Characteristics and Main CharacteristicsSeptember 16, 20221. Characteristics of electrophoresis surface treatment processElectrophoretic paint film has the advantages of full, uniform, flat and smooth coating. The hardness, adhesion, corrosion resistance, im...view CNC Machining Services and Engineered Machined Products: Meeting Manufacturing NeedsNovember 7, 2023Are you looking to understand the world of CNC machining and engineered machined products better? You're in the right place! I'm here to guide you through the intricate world of CNC machining, engineered machined products, and how Richconn can be your trusted partner in this journey.view

CNC Machining Services and Engineered Machined Products: Meeting Manufacturing NeedsNovember 7, 2023Are you looking to understand the world of CNC machining and engineered machined products better? You're in the right place! I'm here to guide you through the intricate world of CNC machining, engineered machined products, and how Richconn can be your trusted partner in this journey.view CNC Powder Coating in Healthcare Equipment ApplicationsFebruary 29, 2024In the world of healthcare equipment, precision and durability are of the utmost importance. From monitoring devices to surgical tools, every piece of equipment must be able to withstand the demanding...view

CNC Powder Coating in Healthcare Equipment ApplicationsFebruary 29, 2024In the world of healthcare equipment, precision and durability are of the utmost importance. From monitoring devices to surgical tools, every piece of equipment must be able to withstand the demanding...view

EN

EN

ru

ru