Metalworking would not be possible in the present day without the various techniques of heat treatments. It could be argued that the absence of heat treatment would significantly alter the modern way of life. Heat treating, a vital procedure in the production of metal and alloy components, provides numerous long-term advantages. Ranging from enhanced strength and ductility to improved resistance to corrosion and beyond, heat treating ensures safety, longevity, and cost-effectiveness for firms that utilize metal components in diverse sectors such as aerospace, renewable energy, and forged wheel manufacturing.

This blog post takes an in-depth look at the process of metal heat treatment. It’s important to understand how it plays a role in the manufacturing process when you are looking to source metal parts. This article is your ultimate guide on heat treatment, aimed at serving as a helpful resource by outlining various methods and their advantages. Additionally, important tips for the heat treatment process will be provided.

Although most people don’t know about it. What is heat treating? Heat treatment of steel involves the heating then cooling process of the material. The metal or alloy is heated to a specific temperature. Then, cooling occurs to harden the heated material. The objective of this method is to modify the microstructure of the metal, as well as to enhance its intended mechanical, chemical, and physical properties.

Heat treatment can be used at different stages in the manufacturing process to change certain properties of that metal or alloy. For example, you might use heat treatment to make it stronger, harder, more durable, or more ductile, depending on what the material needs to perform properly.

Several significant industries that rely on heat treatment include aviation, automotive, tools (e.g., saws and axes), technology (computers), aerospace, defense, and the petroleum industry.

Heat treatment involves four stages: heat deflection temperature meaning that heating the material, allowing it to "soak" at a specific temperature, and then cooling it. Each step is critical in the heat treatment process to effectively modify the structural composition of the material.

1. Heating Stage

In the first phase of heat treatment, the material is heated to a specific temperature. The objective at this stage is to ensure uniform heating of the metal, which necessitates a gradual heating process. Uneven heating can lead to differential expansion, potentially resulting in distortion or cracks in specific sections of the metal.

2. Soaking Stage

The second stage is referred to as the soaking stage, which takes place once the material reaches the specific temperature during the first heating process and is then maintained at that temperature for a set duration. The aim of maintaining a constant temperature is to facilitate the desired internal structure formation. The duration for which the material is kept at a specific temperature is known as the "soaking period," which is determined by the material's chemical composition, mass, and shape, particularly in cases of uneven cross-sections.

3. Cooling Stage

Subsequently, the material is cooled, typically rapidly, based on the desired outcomes. The purpose of the cooling phase is to return the metal to room temperature. How the cooling process is conducted affects the result, such as the hardness of the metal.

At this juncture, the metallurgist must be knowledgeable about the metal's composition and determine whether a cooling medium, whether it be gas, liquid, solid, or a combination, is necessary to swiftly cool the component to achieve the desired impact.

4. Aging Stage

Without the aging process, a solution will not be effective as it lacks mechanical strength and hardness. Aging is essential for hardening. A complete heat treatment process encompasses heat treatment, soaking, cooling, and aging.

As mentioned earlier, every heat treatment process involves heating and cooling. In this section, we’ll discuss the four major heat treatment types. You will also understand some common purposes in machining hot rolled steel, like 4140. 4140 heat treatment metal is a versatile alloy, known for its exceptional strength, toughness, and PLA heat resistance.

Annealing

Annealing is a heat treatment method where a metal such as aluminum, copper, steel, silver, or brass is heated to a specific temperature, held at that temperature for some time to allow transformation to occur, and then air cooled. For example, 4140 heat treated steel is heated beyond the upper critical temperature and then cooled at a slow rate by air, not by liquid or oil.

The purpose of the annealing heat treating method is to soften the metal (decreasing the hardness), making it more conducive to cold working and forming processes. Annealing helps alleviate any stresses within the metal that may have accumulated from earlier cold working procedures. As a result, annealing improves the metal's machinability, ductility, and toughness.

Normalizing

Normalizing is a type of annealing process, where the metal is heated to a temperature of 90°C, which is higher than in annealing. The metal is kept at this critical temperature until the desired transformation takes place. Following the heating process, air cooling is necessary.

This method results in the formation of smaller austenitic grains, while air cooling helps in creating more refined ferritic grains. It aids in the elimination of internal stress in metals, which could potentially cause metal failure. Therefore, it is crucial to normalize the heat treating 4140 metals. Then, hardening can ensure the success of manufacturing processes.

Quenching

Quenching is a component of the cooling phase where metal is rapidly cooled in air, oil, water, brine, or a different medium. It typically results in the hardening of the material due to the rapid cooling process, although this may not always be the case. Sometimes, water quenching is employed to anneal copper. Furthermore, metallurgists must comprehend which metals can undergo quenching, as improper quenching techniques may lead to the warping or cracking of certain metals.

Water or brine are typically chosen for rapid cooling, while oil is commonly recommended for slower cooling processes. Quenching is often linked with hardening because most metals that undergo hardening are rapidly cooled through quenching. However, it is not always the case that quenching or other rapid cooling methods lead to hardening. For instance, water quenching is utilized to anneal copper, while other metals may be hardened through slow cooling processes.

Hardening

Hardening is the procedure of strengthening steel to enhance its hardness and reduce brittleness. While Annealing represents the "Yin", Hardening serves as the "Yang" in terms of heat treatment, providing the opposite effects of Annealing. An essential aspect of the metalworking process, hardening can often be observed when observing a blacksmith crafting a sword or a knife.

During hardening, the metal is heated to a temperature 40°C higher than its critical temperature and then rapidly cooled by immersion in oil or water. At times, a brine solution is used instead of water to prevent the formation of bubbles on the metal surface. The outcomes of hardening can be witnessed in various objects such as knives, swords, gears, taps, dies, and chisels.

Tempering

Hardening can cause the metal to become brittle in places depending on the thickness of the metal being hardened. The typical next step when using the Hardening method to heat treat thin metals such as blades is to temper it. Tempering will reduce the brittleness of the metal by removing internal stresses on the metal that developed during the Hardening process.

The usual process for tempering metal is to take the freshly hardened piece and reheat the metal back up. This heating point is usually at a range between ambient temperature and critical point temperature. This temperature could reach as high as 700°C and once this temperature is reached, the metal will stay ensconced for a period of time. Tempering is typically done in an oil bath or molten lead bath and the holding time at top heat is based on the type of metal used and the desire of hardness in the metal.

Improved Mechanical Properties

One of the primary benefits of heat treatment is enhancing a metal’s mechanical properties. Depending on the specific process used, heat treatment can increase hardness, strength, toughness, and ductility. Heat treating 4140 is the example that was subjected to heat treatments to improve their stability. Therefore, they have better surface hardness, ductility, and strength.

4140 heat treat chart | ||

Element | Purpose | Content |

Chromium | Hardness penetration | 0.8 - 1.1% |

Carbon | Hardness | 0.38 - 0.43% |

Manganese | Wear resistance | 0.5 - 1% |

Molybdenum | High temperature stability | 0.15 - 0.25% |

Silicon | Deoxidization | 0.15 - 0.3% |

Sulfur | Corrosion resistance | 0.04% |

Phosphorus | Machinability | 0.04% |

Increased Wear Resistance

Heat treatment plays a crucial role in improving a metal's ability to withstand wear and tear, thereby enhancing its durability in scenarios where it may encounter friction or abrasive wear, such as in engine components and cutting tools.

Improved Machinability

Certain heat treatment procedures can facilitate the cutting, shaping, or machining of metals. One example is annealing, which has the effect of rendering a metal more pliable, thus simplifying the working process.

Stress Relief

Through heat treatment, internal stresses within a metal, potentially induced during welding or casting, can be alleviated. This can serve to prevent issues such as distortion or fracturing.

Enhanced Electromagnetic Properties

Certain heat treatment techniques can improve the electrical and magnetic characteristics of metals, rendering them more suitable for utilization in electrical components and equipment.

Enhanced Heat and Corrosion Resistance

Another significant advantage of heat treatment is its capability to enhance a metal's resistance to both high temperatures and corrosion. This improved resistance makes the metal suitable for operating in challenging environments where exposure to extreme heat or corrosive elements is a concern, ensuring long-lasting durability and performance.

Enhanced Dimensional Stability

Heat treatment can ensure that metal retains its form and dimensions under diverse conditions, a crucial aspect in precision CNC machining operations.

Type of Metal

Various metals exhibit unique responses to heat treatment, primarily as a result of variances in their composition and crystalline arrangement. For instance, the reaction of steel to heat treatment differs from that of aluminum or copper.

Alloy Composition Influence

The presence and levels of diverse alloying components in a metal play a crucial role in dictating its reaction to heat treatment. For example, the carbon content in steel is a determining factor in whether it can be hardened through heat treatment.

Heating Temperature

The temperature to which a metal is subjected during heat treatment plays a pivotal role in determining the metal's ultimate properties. Higher temperatures can bring about more pronounced alterations in the metal's internal structure, which may enhance hardness but could potentially increase brittleness.

Cooling Speed

The speed at which a metal is cooled following heating also plays a significant role in shaping its final properties. Swift cooling, known as quenching, can elevate hardness, whereas slower cooling can yield a softer, more malleable metal.

Duration of Heat Treatment

The duration for which the metal is maintained at the heat treatment temperature can have a significant impact on the resulting outcome. In certain procedures, prolonging the metal's exposure to the treatment temperature may result in enhanced hardness or other sought-after properties.

Pre-Treatment Mechanical Manipulation

The prior mechanical treatment of a metal can have a bearing on how it reacts to heat treatment. For instance, a metal that has undergone extensive cold-working may exhibit different responses to heat treatment compared to a metal that has not undergone such manipulation.

The heat treatment of metals is an effective method for enhancing their mechanical characteristics. In addition to physical improvements, it can also enhance the electrical and magnetic properties of metals, thereby enhancing their compatibility with other materials.

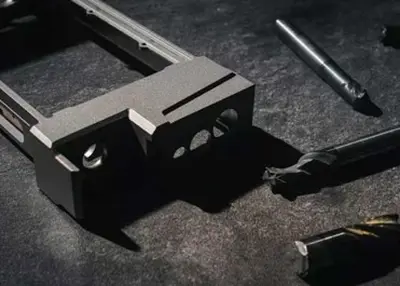

Having understood the significance of diverse heat treatment methods in enhancing your products, it is essential to entrust your project to experts to achieve the desired outcomes. Richconn provides a seamless solution for obtaining precisely customized parts with heat treatment. We take pride in our state-of-the-art facilities that perform a wide range of thermal processing procedures. At Richconn, our heat treatment processes are conducted by top-notch technicians and engineers in the field, ensuring quality and precision. With rich knowledge and expertise, we are committed to delivering exceptional services that cater to your individual needs. You can expect reliable support and products tailored to meet your specific requirements, all at competitive prices.

Dual-tone Baking Paint Technology: Achieving Unique Visual EffectsJuly 31, 2023Have you seen two-tone colored cars, phones, appliances, buildings? Want to understand how to achieve two-tone baked paint? This article introduces this unique parts painting technique in detail, expl...view

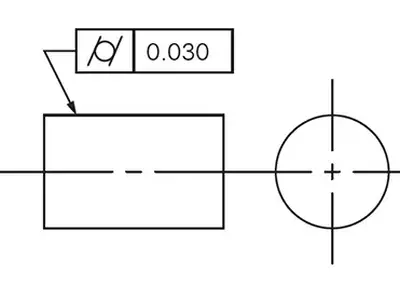

Dual-tone Baking Paint Technology: Achieving Unique Visual EffectsJuly 31, 2023Have you seen two-tone colored cars, phones, appliances, buildings? Want to understand how to achieve two-tone baked paint? This article introduces this unique parts painting technique in detail, expl...view What Are Tolerances? How Are Tolerances Determined When Designing Machinery?October 26, 2023Tolerance is precise machining and design, the actual parameter values of the parts of the allowable amount of change, such as a certain part of the upper and lower limits were 100, 60, then its tolerance is 40; if the upper and lower limits were +100, -100, then its tolerance is 200.view

What Are Tolerances? How Are Tolerances Determined When Designing Machinery?October 26, 2023Tolerance is precise machining and design, the actual parameter values of the parts of the allowable amount of change, such as a certain part of the upper and lower limits were 100, 60, then its tolerance is 40; if the upper and lower limits were +100, -100, then its tolerance is 200.view Unlocking Precision: Mastering Cylindricity for Engineering ExcellenceNovember 21, 2023In the intricate world of engineering, precision reigns supreme. Enter the realm of cylindricity - a fundamental attribute dictating the perfection of cylindrical forms. Here, I guide you through an explorative journey, unveiling the essence of cylindricity, its nuanced applications in GD&T (Geometric Dimensioning and Tolerancing), and the crucial methods to measure and comprehend this vital parameter.view

Unlocking Precision: Mastering Cylindricity for Engineering ExcellenceNovember 21, 2023In the intricate world of engineering, precision reigns supreme. Enter the realm of cylindricity - a fundamental attribute dictating the perfection of cylindrical forms. Here, I guide you through an explorative journey, unveiling the essence of cylindricity, its nuanced applications in GD&T (Geometric Dimensioning and Tolerancing), and the crucial methods to measure and comprehend this vital parameter.view 6 Avoidable Mistakes When Designing CNC PartsOctober 13, 2023A common mistake is designing parts with surfaces where material removal would actually be unnecessary. Unnecessary machining contributes to longer machining times, and that greatly impacts the final production cost.view

6 Avoidable Mistakes When Designing CNC PartsOctober 13, 2023A common mistake is designing parts with surfaces where material removal would actually be unnecessary. Unnecessary machining contributes to longer machining times, and that greatly impacts the final production cost.view Comprehensive Insights into Metal Polishing Techniques and BenefitsJanuary 26, 2024Metal polishing is a reliable post-treatment process to enhance the surface quality of machined metal parts. Read on to discover more about metal polish.view

Comprehensive Insights into Metal Polishing Techniques and BenefitsJanuary 26, 2024Metal polishing is a reliable post-treatment process to enhance the surface quality of machined metal parts. Read on to discover more about metal polish.view Alodine: A Versatile and Effective Coating for AluminumDecember 5, 2023Alodine is a trade name for a chromate conversion coating that protects aluminum and other metals from corrosion. A chromate conversion coating is a thin layer of chromium compounds that forms on the surface of a metal when it reacts with a chromate solution.view

Alodine: A Versatile and Effective Coating for AluminumDecember 5, 2023Alodine is a trade name for a chromate conversion coating that protects aluminum and other metals from corrosion. A chromate conversion coating is a thin layer of chromium compounds that forms on the surface of a metal when it reacts with a chromate solution.view