Tensile strength is a key characteristic that engineers and materials specialists must consider when designing and selecting materials for their applications. It is the maximum stress that a material can withstand before it breaks or deforms under tension.

Here, we will give you an overview of tensile strength and related concepts. We will cover stress and strain, the factors that affect it, how it is measured, and its importance in engineering and applications.

This will enable you to make informed decisions, optimize designs and ensure safety and efficiency. It is particularly helpful for industries such as aerospace, automotive, civil engineering and energy.

Tensile strength can be an important point of interest for many engineers and materials specialists. In the simplest terms, tensile strength is the amount of stress an object can resist before it breaks or deforms when subjected to a force that pulls it apart. To understand it, you must first familiarize yourself with the related concepts of stress and strain. Stress is the external force that causes a material to bend or deform, while strain is the result of the force applied to the material.

Tensile stress is a stress that stretches or elongates a material. On the other hand, compression squeezes the material while shear applies opposite forces along different planes.

When measuring tensile strength, it is important to consider yield strength, ultimate strength, and breaking strength. All three measurements track how much force an object can withstand without being permanently damaged. Yield strength indicates how much force is needed to cause a permanent change in shape, while ultimate strength indicates the total resistance beyond its elastic limit.

Finally, the breaking strength provides the limit of damage, and once this threshold is exceeded, catastrophic failure can occur. Tensile strength can be measured in different materials and units, including pounds per square inch (psi) or megapascals (MPa). These units allow researchers and engineers to gain insight into potential project and product design applications based on their knowledge of the context of each project.

Tensile strength is affected by a variety of factors. These include material composition (as the product may be essentially metallic or polymeric, ceramic or composite), temperature, strain rate and any manufacturing process involved.

The tensile strength of a polymer can be altered to suit the application using reversible or irreversible methods (e.g. cross-linkers and plasticizers). These are important for molding and injection molding of polymer materials.

For metals, changing the heat treatment process may result in significant changes in properties such as hardness, ductility and tensile strength. Understanding these factors helps to produce quality materials that can be used not only for engineering purposes, but also for common objects with unique properties that depend on composition and temperature.

Similarly, other forms of damage, such as fatigue and cracking due to usage loads, are related to tensile strength, which needs to be taken into account if longer-lasting products must be designed from these materials. High priority should also be given to manufacturing defects, such as cold welds between two surfaces that come into contact during assembly operations, resulting in poor interlocking tensile strength at the finished joint.

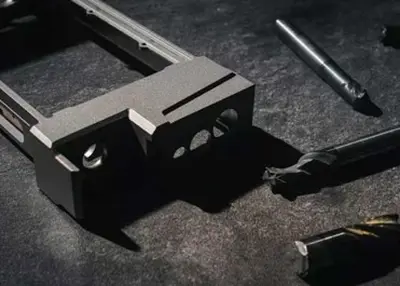

Understanding just how these factors affect tensile strength provides a broad understanding of product optimization through many applications across industries to maximize its value when used in everyday environments or in CNC machining services.

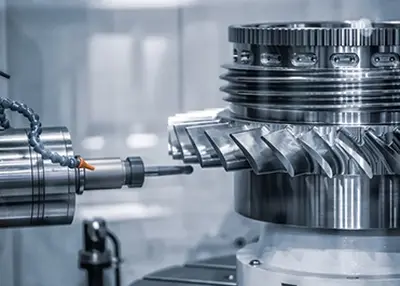

Tensile testing is a critical process for determining the strength and elasticity of materials. In order to measure tensile strength, the preparation of test specimens is essential to ensure accurate and reliable results.

This process involves molding the material into a standard-sized sample and attaching it to a testing machine so that the force is applied evenly to both ends. The stress-strain curve generated by this test measures the force required to fracture or deform the sample.

Ultrasonic testing uses high-frequency sound waves to detect defects, deformations, thickness variations, or other anomalies in the part or object under test.

Magnetic particle testing can detect hidden cracks by magnetizing a surface, which generates an electromagnetic field when an electric current is passed through it.

Eddy current testing can be used to evaluate electrically conductive materials, such as conductor rods or cables, by measuring the change in resistance when this method is performed on them.

These features are useful when you need to accurately measure tensile strength without compromising the integrity of the material under test.

Tensile strength plays an important role in engineering for both material selection and design considerations. Its importance in material selection is critical for industries such as aerospace, automotive, civil engineering and energy.

Understanding its precise value helps you make more informed decisions about the best materials to use in any given application. In addition, it can inform various design considerations such as safety factors, material optimization and stress analysis. You can ensure that your design meets all safety requirements while ensuring that the results are cost-effective and optimized for efficient performance.

Engineers must consider a variety of factors when selecting materials, and tensile strength is one of them. After all, it determines how much force a material can withstand under tension without breaking or permanently deforming.Richconn is a precision machine shop established in 2008, we have a lot of experience in the selection of materials for CNC machining, if you need CNC turning services or CNC milling services, you can contact us, we have a good understanding of metal materials. We have deep understanding of metal materials.

Everything You Need to Know About CNC Machine ShopSeptember 13, 2023Are you looking to find a CNC machine shop in China? This article covers the information you need to know and helps you choose the best partner.view

Everything You Need to Know About CNC Machine ShopSeptember 13, 2023Are you looking to find a CNC machine shop in China? This article covers the information you need to know and helps you choose the best partner.view How to Find an Excellent Precision Machining Manufacturer in China?October 19, 2023China is one of the more developed countries in the global manufacturing industry, so it is not difficult to find an excellent precision machining manufacturer in China, but how to find a reliable quality, good service, reasonable price precision machining manufacturer in China, it is necessary for consumers to make a careful assessment when choosing.view

How to Find an Excellent Precision Machining Manufacturer in China?October 19, 2023China is one of the more developed countries in the global manufacturing industry, so it is not difficult to find an excellent precision machining manufacturer in China, but how to find a reliable quality, good service, reasonable price precision machining manufacturer in China, it is necessary for consumers to make a careful assessment when choosing.view Comprehensive Insights into Metal Polishing Techniques and BenefitsJanuary 26, 2024Metal polishing is a reliable post-treatment process to enhance the surface quality of machined metal parts. Read on to discover more about metal polish.view

Comprehensive Insights into Metal Polishing Techniques and BenefitsJanuary 26, 2024Metal polishing is a reliable post-treatment process to enhance the surface quality of machined metal parts. Read on to discover more about metal polish.view The Ultimate Guide to Different Types of Screws 2024January 10, 2024Screws are one of the most common fasteners in the world. Let’s discover various types of screws, materials, and applications. Get tailored excellence in fastening solutions!view

The Ultimate Guide to Different Types of Screws 2024January 10, 2024Screws are one of the most common fasteners in the world. Let’s discover various types of screws, materials, and applications. Get tailored excellence in fastening solutions!view Richconn Expands its Rapid CNC Service with High Performance Aluminum 5083October 11, 2023As the world's leading rapid prototyping companies, we have added Aluminum 5083-H111 (3.3547 or AlMg4.5Mn0.7) to our line of more than 40 in-stock metals and plastics materials for quick turnaround CNC service.view

Richconn Expands its Rapid CNC Service with High Performance Aluminum 5083October 11, 2023As the world's leading rapid prototyping companies, we have added Aluminum 5083-H111 (3.3547 or AlMg4.5Mn0.7) to our line of more than 40 in-stock metals and plastics materials for quick turnaround CNC service.view Metal Milling Techniques and ApplicationsNovember 3, 2023Are you fascinated by the art of shaping metal into precision components or intricate designs? In this comprehensive guide, I'll walk you through the world of metal milling, from the fundamental concepts to advanced applications.view

Metal Milling Techniques and ApplicationsNovember 3, 2023Are you fascinated by the art of shaping metal into precision components or intricate designs? In this comprehensive guide, I'll walk you through the world of metal milling, from the fundamental concepts to advanced applications.view

EN

EN

ru

ru