Before the Industrial Revolution, human beings didn't have much need for energy. For example, we were happy to use the sun's energy to heat our homes, horses for transportation, wind power to sail around the world, and water to power simple machines that ground grain.17 In the 1980s, everything changed with the rapid growth of steam-powered electric power plants, most of whose components were manufactured using high-speed machine tools.

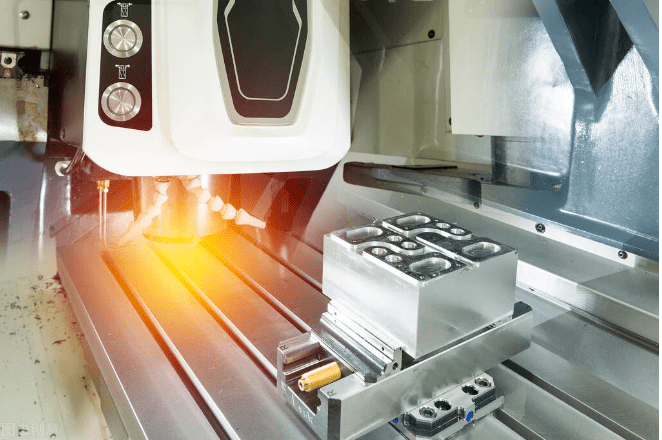

However, since the beginning of rapid industrialization, energy systems and technologies have become more complex as energy demand continues to grow. As a result, it became more challenging for manufacturers to meet the manufacturing requirements of the energy industry until the advent of CNC machining technology in 1952.

In this article, we will cover CNC machining in the energy industry. We'll cover three things you must know about CNC machines and their role in today's energy sector. So let's get started!

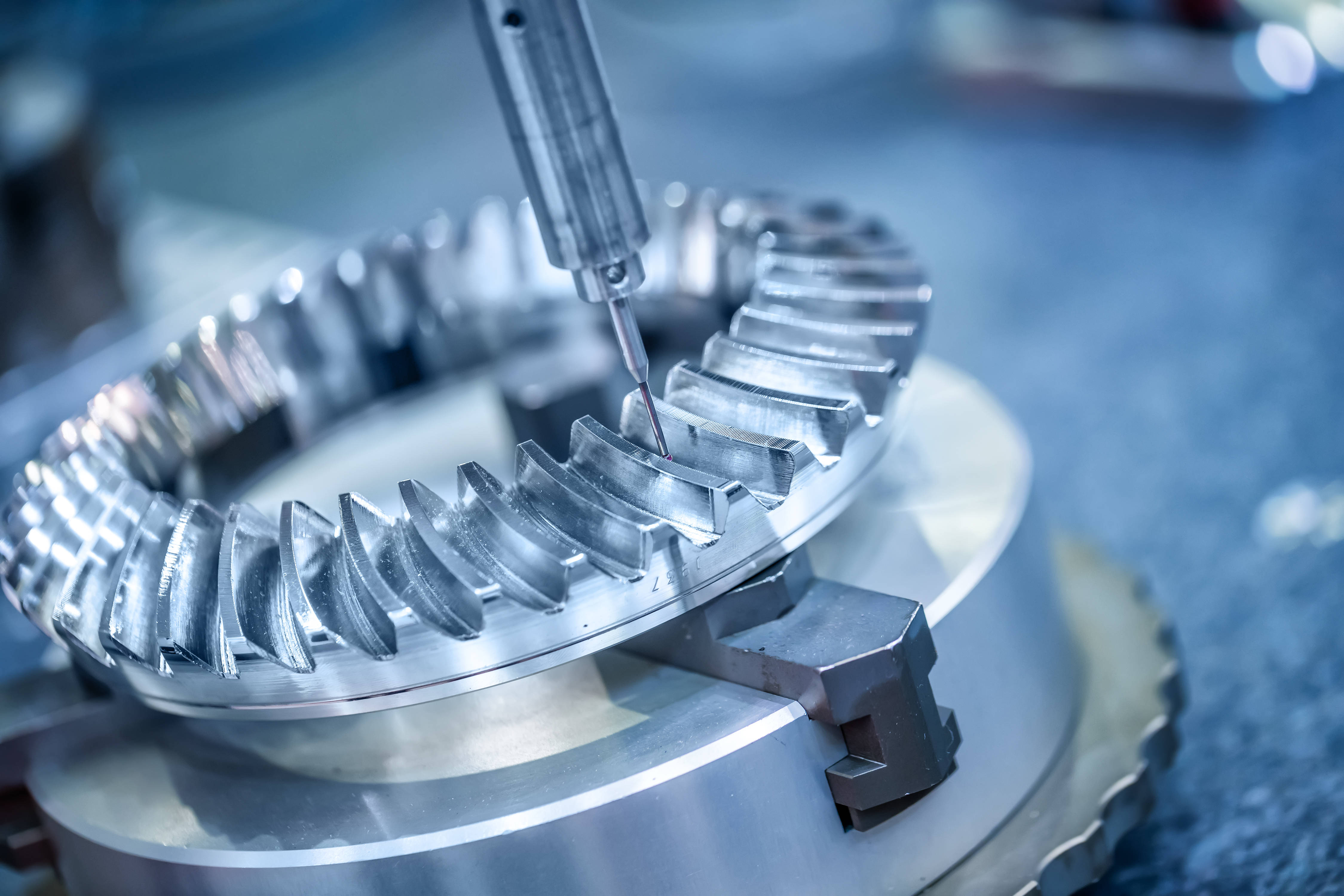

Hydroelectric turbines and generators are huge, consisting of hundreds of thousands of components. These components vary in design and size, with some components smaller than an index finger and others larger than an automobile. Regardless of the variations in size, a key requirement is that these components are precisely machined to ensure seamless assembly.

CNC machines are one of the key machining technologies used by product designers in the energy industry to meet these requirements. Some manufacturers, for example, rely on 7-axis CNC milling machines to manufacture most of the components that make up their 36-foot-long, 25-ton hydroelectric systems.

The reasons for this heavy reliance on CNC machines are understandable. First, CNC machines can machine tolerances as small as 4 μm, which is nearly the tolerance limit for many hydropower components such as simple shafts, impellers, and bushings. Secondly, multi-axis CNC machines are particularly well suited to manufacturing extremely large and complex geometries.

However, the application of CNC machine tools is not limited to the renewable energy industry.

Like hydroelectric systems, conventional turbines and generators (which rely on fossil fuels to produce electricity) have thousands of components. However, unlike renewable energy systems, conventional generator components are subjected to extremely high thermal conditions of up to 2,300°F, leading engineers to rely on high-strength and heat-resistant materials for these components.

Finding a material with high strength and heat resistance is not a problem for product designers. Instead, the challenge is finding the right manufacturing method for these metals. For example, high-strength materials such as titanium and its alloys have poor (or average) machinability and are prone to chatter during metal cutting.

Because CNC machines are compatible with a wide range of materials, Machining manufacturer relies on them to manufacture difficult-to-machine metals in conventional generators and turbines. For example, skilled machinists typically CNC-machine titanium at a recommended cutting speed of 59 m/min for roughing and more than 180 m/min for finishing.

Solar and wind power systems are slowly taking center stage on the global stage, replacing conventional energy systems that rely on fossil fuels and contribute to climate change. As a result, research is being conducted to improve the efficiency and performance of these systems. For example, a number of research scientists are studying new wind turbine blade designs and the energy efficiency and performance of solar panels.

As you may have guessed, CNC machine tools are one of the technologies used for rapid prototyping of the blades and solar panels used in most of these studies. One of the main reasons for this preference is the ease of modifying designs in CNC machining.

With Richconn's CNC machining services, all you have to do is modify the dimensions on your 3D CAD software, and our CNC machinists will have no problem quickly fabricating your new blade (or solar panel design). This is not the case with traditional manufacturing methods such as injection molding, where you have to start from scratch by recreating the mold.

CNC Powder Coating in Healthcare Equipment ApplicationsFebruary 29, 2024In the world of healthcare equipment, precision and durability are of the utmost importance. From monitoring devices to surgical tools, every piece of equipment must be able to withstand the demanding...view

CNC Powder Coating in Healthcare Equipment ApplicationsFebruary 29, 2024In the world of healthcare equipment, precision and durability are of the utmost importance. From monitoring devices to surgical tools, every piece of equipment must be able to withstand the demanding...view 6 Aspects of Optimizing Part Design For CNC MachiningOctober 16, 2023The rapid and cost-effective production of prototypes and series parts by CNC machining is often a balancing act. Both the capabilities of the manufacturing process and the part itself as an optimized, functional component must be considered. So when designing parts for machining with Richconn milling and CNC turning parts, there are a few key points to consider to shorten manufacturing time and reduce costs.view

6 Aspects of Optimizing Part Design For CNC MachiningOctober 16, 2023The rapid and cost-effective production of prototypes and series parts by CNC machining is often a balancing act. Both the capabilities of the manufacturing process and the part itself as an optimized, functional component must be considered. So when designing parts for machining with Richconn milling and CNC turning parts, there are a few key points to consider to shorten manufacturing time and reduce costs.view The Importance of Material Science in Component Interaction.October 18, 2023Even a perfectly designed injection molded part can potentially disappoint if it is made from the wrong material. It is often difficult to select the right materials from hundreds of thermoplastics and elastomers to meet the requirements of the application. A variety of factors, such as mechanical strength, UV resistance, lubricity, wear resistance, and chemical and UV resistance should be carefully considered when selecting materials for injection molding.view

The Importance of Material Science in Component Interaction.October 18, 2023Even a perfectly designed injection molded part can potentially disappoint if it is made from the wrong material. It is often difficult to select the right materials from hundreds of thermoplastics and elastomers to meet the requirements of the application. A variety of factors, such as mechanical strength, UV resistance, lubricity, wear resistance, and chemical and UV resistance should be carefully considered when selecting materials for injection molding.view What is Precision Grinding & Types, Materials, ProcessesNovember 27, 2023The so-called precision grinding process is to utilize fine-grained abrasive grains and micro-powder to process ferrous metals, hard and brittle materials, etc., in order to obtain high machining accuracy and low surface roughness values.view

What is Precision Grinding & Types, Materials, ProcessesNovember 27, 2023The so-called precision grinding process is to utilize fine-grained abrasive grains and micro-powder to process ferrous metals, hard and brittle materials, etc., in order to obtain high machining accuracy and low surface roughness values.view The Ultimate Guide to Different Types of Screws 2024January 10, 2024Screws are one of the most common fasteners in the world. Let’s discover various types of screws, materials, and applications. Get tailored excellence in fastening solutions!view

The Ultimate Guide to Different Types of Screws 2024January 10, 2024Screws are one of the most common fasteners in the world. Let’s discover various types of screws, materials, and applications. Get tailored excellence in fastening solutions!view CNC Piston Machining: Crafting High-Quality Engine ComponentsNovember 7, 2023Are you in pursuit of engine components that combine precision, reliability, and performance? Your quest for top-notch CNC piston machining ends here. In this comprehensive guide, I will take you on a journey through the intricacies of CNC piston machining, shedding light on the processes, technologies, and services that define this critical aspect of engine manufacturing.view

CNC Piston Machining: Crafting High-Quality Engine ComponentsNovember 7, 2023Are you in pursuit of engine components that combine precision, reliability, and performance? Your quest for top-notch CNC piston machining ends here. In this comprehensive guide, I will take you on a journey through the intricacies of CNC piston machining, shedding light on the processes, technologies, and services that define this critical aspect of engine manufacturing.view

EN

EN

ru

ru