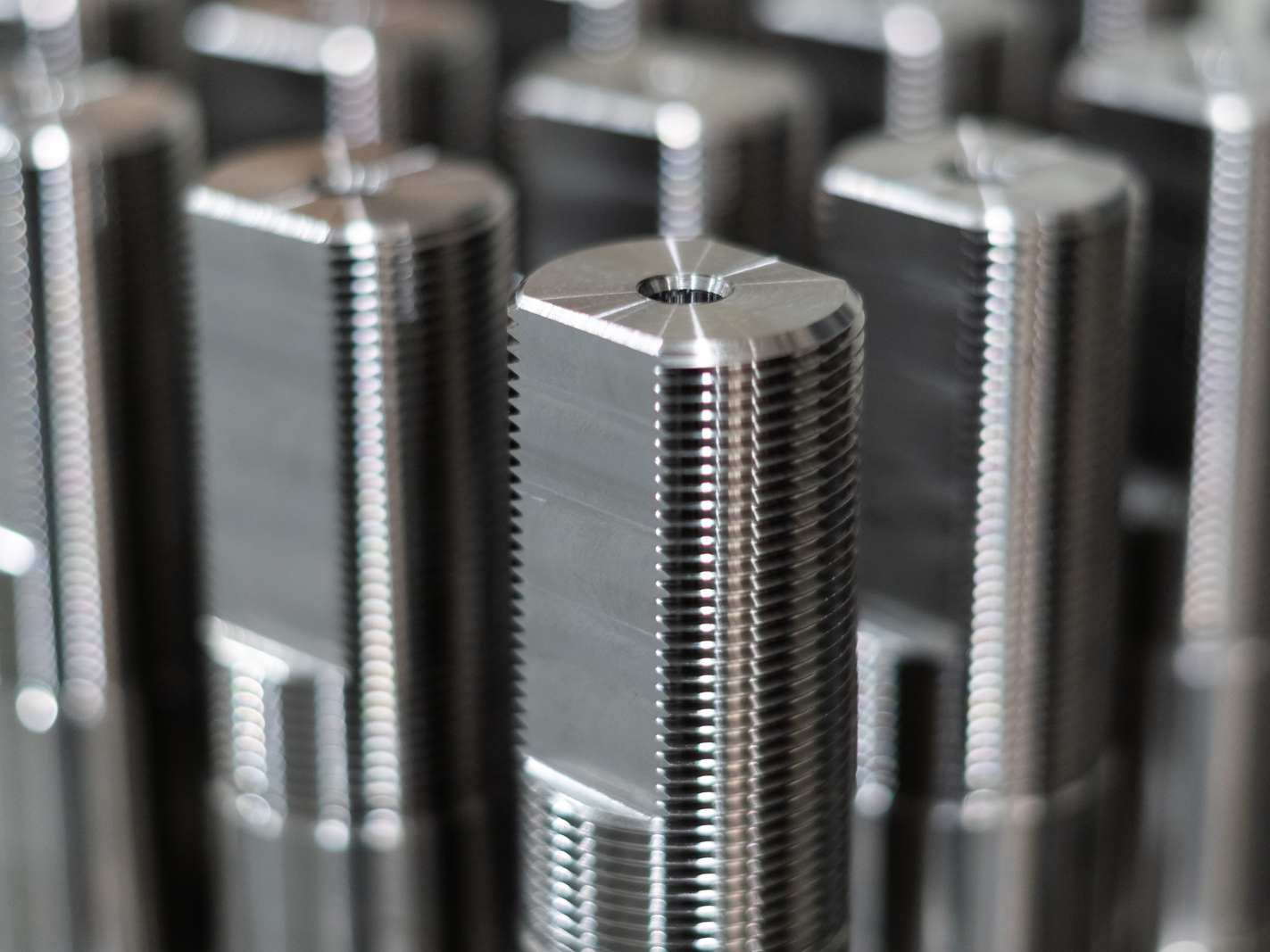

In CNC machining, the usual process is to use a drill bit to drill a hole in the workpiece and then use a tap of the appropriate size to cut the desired threads in the hole. This ensures that the threads match the design requirements and can ensure that the threads fit correctly with other components.

These tools are used in custom CNC machining to create the required threads on a part in order to connect it to other parts or components.

A drill is a tool used for drilling holes, usually made of steel, with a cutting edge and a shank. A tap is a tool used to form internal threads, also made of steel. When making threads, it is necessary to first drill a suitable hole with a drill bit, and then use a tap of the corresponding specifications to make deep cuts to form a threaded structure.

The following is a table of drill and tap specifications to make it easier to determine the matching relationship between drills and taps. When selecting the correct tap specification, please choose the appropriate drill specification according to the size of the threads to be made to ensure a proper matching relationship between the threads and the drill.

1. Tap specification table

| Type | Drill Diameter | Tap Specification |

|---|---|---|

| Metric Coarse Thread (M) | 3.0mm | M3 |

| Metric Coarse Thread (M) | 3.5mm | M4 |

| Metric Coarse Thread (M) | 4.2mm | M5 |

| Metric Coarse Thread (M) | 5.0mm | M6 |

| Metric Coarse Thread (M) | 6.8mm | M8 |

| Metric Coarse Thread (M) | 8.5mm | M10 |

| Metric Coarse Thread (M) | 11.0mm | M12 |

| Metric Coarse Thread (M) | 14.0mm | M16 |

| Metric Coarse Thread (M) | 18.0mm | M20 |

| Imperial Coarse Thread (UNC) | 4.8mm | 1/4-20UNC |

| Imperial Coarse Thread (UNC) | 6.5mm | 5/16-18UNC |

| Imperial Coarse Thread (UNC) | 8.5mm | 3/8-16UNC |

| Imperial Coarse Thread (UNC) | 10.5mm | 7/16-14UNC |

| Imperial Coarse Thread (UNC) | 12.5mm | 1/2-13UNC |

| Imperial Coarse Thread (UNC) | 16.5mm | 5/8-11UNC |

| Imperial Coarse Thread (UNC) | 19.5mm | 3/4-10UNC |

| Imperial Coarse Thread (UNC) | 22.5mm | 7/8-9UNC |

| Imperial Coarse Thread (UNC) | 25.5mm | 1-8UNC |

| Imperial Fine Thread (UNF) | 4.2mm | 4-40UNF |

| Imperial Fine Thread (UNF) | 5.6mm | 6-32UNF |

| Imperial Fine Thread (UNF) | 6.8mm | 8-32UNF |

| Imperial Fine Thread (UNF) | 8.5mm | 10-24UNF |

| Imperial Fine Thread (UNF) | 10.5mm | 12-24UNF |

| Imperial Fine Thread (UNF) | 12.5mm | 1/4-28UNF |

| Imperial Fine Thread (UNF) | 16.5mm | 5/16-24UNF |

| Imperial Fine Thread (UNF) | 19.5mm | 3/8-24UNF |

| Imperial Fine Thread (UNF) | 22.5mm | 7/16-20UNF |

| Imperial Fine Thread (UNF) | 25.5mm | 1/2-20UNF |

2. Drill and Tap Matching Chart

| Thread Size | Drill Diameter |

|---|---|

| M3 | 2.5mm |

| M4 | 3.3mm |

| M5 | 4.2mm |

| M6 | 5.0mm |

| M8 | 6.8mm |

| M10 | 8.5mm |

| M12 | 11.0mm |

| M16 | 14.0mm |

| M20 | 18.0mm |

| Thread Size | Drill Diameter |

|---|---|

| 1/4-20UNC | 0.2031in |

| 5/16-18UNC | 0.2570in |

| 3/8-16UNC | 0.3238in |

| 7/16-14UNC | 0.3770in |

| 1/2-13UNC | 0.4063in |

| 5/8-11UNC | 0.5156in |

| 3/4-10UNC | 0.6094in |

| 7/8-9UNC | 0.7031in |

| 1-8UNC | 0.8125in |

| Thread Size | Drill Diameter |

|---|---|

| 4-40UNF | 3/32in |

| 6-32UNF | 7/64in |

| 8-32UNF | 9/64in |

| 10-24UNF | 5/32in |

| 12-24UNF | 11/64in |

| 1/4-28UNF | 1/4in |

| 5/16-24UNF | 5/16in |

| 3/8-24UNF | 3/8in |

| 7/16-20UNF | 7/16in |

| 1/2-20UNF | 1/2in |

This article provides a table of drill and tap specifications, so that you can easily choose the correct tap specifications to avoid difficulties in the work. When using drills and taps, please follow the precautions to ensure the quality and accuracy of the threads.

Anodized Aluminum: How to Anodize Aluminum Parts?January 23, 2024Are you familiar with anodizing aluminum? If not, you can read this article and get to know about the process and other related things.view

Anodized Aluminum: How to Anodize Aluminum Parts?January 23, 2024Are you familiar with anodizing aluminum? If not, you can read this article and get to know about the process and other related things.view The Role of CNC Machining in the Automotive IndustryApril 25, 2023CNC machining is commonly used for complex designs, small products, and parts. Through CNC machine tools, a variety of parts can be machined more accurately.With the rapid development of the automotiv...view

The Role of CNC Machining in the Automotive IndustryApril 25, 2023CNC machining is commonly used for complex designs, small products, and parts. Through CNC machine tools, a variety of parts can be machined more accurately.With the rapid development of the automotiv...view What is a CNC Machine?October 20, 2023The full name of CNC is Computer Numerical Control, and a tooling machine with a computer as the control center is called a CNC machine. The traditional tooling machines need to be manually operated to achieve a variety of metal processing techniques, CNC machine is by the engineers of the computer input product drawings, complete the product required tooling sequence, processing environment parameters and other data, by the computer according to the above instructions for automated production.view

What is a CNC Machine?October 20, 2023The full name of CNC is Computer Numerical Control, and a tooling machine with a computer as the control center is called a CNC machine. The traditional tooling machines need to be manually operated to achieve a variety of metal processing techniques, CNC machine is by the engineers of the computer input product drawings, complete the product required tooling sequence, processing environment parameters and other data, by the computer according to the above instructions for automated production.view Plastics For Medical Devices and ApplicationsOctober 17, 2023Are you designing medical parts? Just as there are countless medical procedures, there is now a seemingly endless abundance of polymer types. Which ones are best suited for medical applications? Good question.view

Plastics For Medical Devices and ApplicationsOctober 17, 2023Are you designing medical parts? Just as there are countless medical procedures, there is now a seemingly endless abundance of polymer types. Which ones are best suited for medical applications? Good question.view![Chamfer 101: Understanding Chamfers and Chamfered Edge [Quick Guide]](/uploads/image/20231123/14/chamfer-101-understanding-chamfers-and-chamfered-edge-quick-guide_400x400.webp) Chamfer 101: Understanding Chamfers and Chamfered Edge [Quick Guide]November 23, 2023Gain comprehensive knowledge about chamfers, including types, advantages and limitations, various methods of measurement and a comparative feature analysis.view

Chamfer 101: Understanding Chamfers and Chamfered Edge [Quick Guide]November 23, 2023Gain comprehensive knowledge about chamfers, including types, advantages and limitations, various methods of measurement and a comparative feature analysis.view Tips On How to Find Low Cost CNC Milling ServicesOctober 24, 2023CNC milling services are not cheap. The more accurate the design you need, the more money you can expect to spend. Reliable machine shops employ professional operators who use state-of-the-art equipment to fulfill orders. As a result, you can't afford to ignore your budget in order to shorten lead times or gain a competitive edge.view

Tips On How to Find Low Cost CNC Milling ServicesOctober 24, 2023CNC milling services are not cheap. The more accurate the design you need, the more money you can expect to spend. Reliable machine shops employ professional operators who use state-of-the-art equipment to fulfill orders. As a result, you can't afford to ignore your budget in order to shorten lead times or gain a competitive edge.view

EN

EN

ru

ru