In order to improve the appearance, texture, function and other properties of metal surface treatment products, it is usually necessary to treat the metal surface. The so-called surface treatment is to form a special surface layer on the surface of the material by physical or chemical methods.

Using the principle of electrochemistry, an aluminum oxide film is formed on the surface of aluminum and aluminum alloys. The main functions of this oxide film are protection, decoration, insulation, and wear resistance. In the process of anodizing, different processes are used for single color, gradient color and double color. The focus of improving the oxidation yield mainly considers the amount of oxidant, suitable temperature and current density.

The role of electrophoresis surface treatment is not only to maintain the luster of the metal surface, but also to enhance the surface properties and have high corrosion resistance. The method is to achieve various colors on the surface of the product for materials such as stainless steel and aluminum alloy. The electrophoresis process is relatively simple, mainly through the three steps of pretreatment-electrophoresis-drying. For a detailed understanding of various metal surface finishes, refer to the metal surface finish chart. Explore the types of metal surface finishes for more detailed information.

The process of using the electrolyte solution to generate the ceramic surface film layer with high voltage electricity, the micro-arc oxidation process is affected by the high power consumption, so the cost is the highest, and the only two colors that can be realized are black and gray.

PVD surface treatment can realize metal surface coating with high hardness and high wear-resisting cermet decorative coating.

The products through electroplating can make the coating glossy and high-quality metal appearance. The electroplating process means that the metal surface is attached to the metal film by electrolysis to play a role in corrosion, which can improve wear resistance, electrical conductivity, reflectivity, aesthetics, etc. .

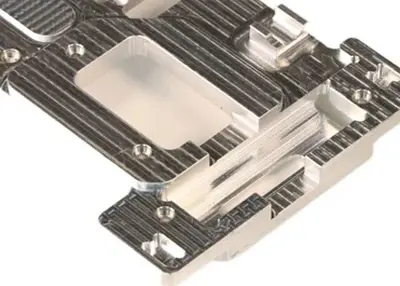

Bulk powder coating is often used for the appearance of architectural furniture products and heat sinks. The powder coating process has five steps: parts - electrostatic dust removal - spraying - low temperature leveling - baking. Under the action of static electricity, it is adsorbed on the surface of the workpiece to form a powder coating, which is baked at high temperature to form different effects.

The process of wire drawing is to make the metal surface produce a non-mirror metallic luster, which can also eliminate subtle defects. It is mainly a means of forming lines on the surface of the workpiece by grinding the product to achieve a decorative effect.

In order to improve the dimensional accuracy and geometric progress of the workpiece, polishing can make the surface of the product smooth and mirror-like. The process is to modify the surface with flexible polishing tools and abrasive particles and other polishing media.

Exposure by plate making, after development, remove the protective film in the area at the desired time, contact the metal with a chemical solution during etching, and use two positive patterns to dissolve and corrode by chemical flooding from both sides, forming a concave-convex or hollow molding effect. There are two ways to realize the process: exposure method and screen printing method.

Plastics For Medical Devices and ApplicationsOctober 17, 2023Are you designing medical parts? Just as there are countless medical procedures, there is now a seemingly endless abundance of polymer types. Which ones are best suited for medical applications? Good question.view

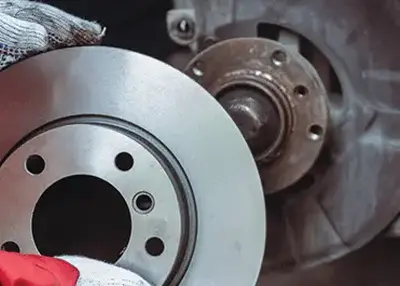

Plastics For Medical Devices and ApplicationsOctober 17, 2023Are you designing medical parts? Just as there are countless medical procedures, there is now a seemingly endless abundance of polymer types. Which ones are best suited for medical applications? Good question.view What Are Machined Rotors?November 8, 2023Welcome to the world of precision engineering, where the subtle details can make a world of difference. In the realm of CNC machining and automotive components, 'Machined Rotors' emerge as a pivotal player, quietly ensuring your safety and vehicle performance.view

What Are Machined Rotors?November 8, 2023Welcome to the world of precision engineering, where the subtle details can make a world of difference. In the realm of CNC machining and automotive components, 'Machined Rotors' emerge as a pivotal player, quietly ensuring your safety and vehicle performance.view What Kind of Parts Are 5-Axis Suitable for Machining?October 30, 2023Over the past few years, CNC machining technology has evolved from simple machines to more complex ones. 5-axis CNC machining is one of the most advanced machining processes available today. It utilizes subtractive machining techniques that offer endless possibilities for part creation. The technology uses cutting tools that work on 5 axes to cut the workpiece into the desired shape and size.view

What Kind of Parts Are 5-Axis Suitable for Machining?October 30, 2023Over the past few years, CNC machining technology has evolved from simple machines to more complex ones. 5-axis CNC machining is one of the most advanced machining processes available today. It utilizes subtractive machining techniques that offer endless possibilities for part creation. The technology uses cutting tools that work on 5 axes to cut the workpiece into the desired shape and size.view What Is CNC Machining? The Basic Information You Need to KnowMarch 27, 2024What is CNC machining? Here is the basic information that you must know, such as its advantages, disadvantages, applications, and so on.view

What Is CNC Machining? The Basic Information You Need to KnowMarch 27, 2024What is CNC machining? Here is the basic information that you must know, such as its advantages, disadvantages, applications, and so on.view Types of Springs | Guidelines, Spring Types, and ApplicationsOctober 18, 2023Springs play a crucial role in various products, providing motion and shock absorption. This article will show you different types of springs and how to choose the right one.view

Types of Springs | Guidelines, Spring Types, and ApplicationsOctober 18, 2023Springs play a crucial role in various products, providing motion and shock absorption. This article will show you different types of springs and how to choose the right one.view What is Precision Machining: Process, Applications & BenefitsAugust 24, 2023Nowadays, the prowess of precision machining lies in the unfaltering delivery of unparalleled quality, precision, and intricacy, which reverberates across a spectrum of industries. With advanced techn...view

What is Precision Machining: Process, Applications & BenefitsAugust 24, 2023Nowadays, the prowess of precision machining lies in the unfaltering delivery of unparalleled quality, precision, and intricacy, which reverberates across a spectrum of industries. With advanced techn...view

EN

EN

ru

ru