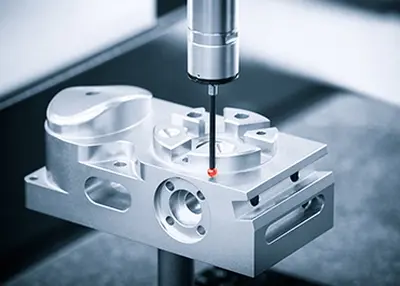

CNC machining is a process that uses computer-controlled machines to create high-quality parts with complex shapes and precise dimensions. It offers many advantages over traditional manufacturing methods. However, not every company has the resources or expertise to invest in CNC machining equipment and personnel. That's why partnering with a CNC company can be a smart and beneficial decision for many businesses.

A CNC company is a type of specialized professional service provider that plays a pivotal role in modern precision manufacturing. These companies are equipped with cutting-edge technology and a team of skilled professionals who are adept at harnessing the power of CNC machining to create high-quality parts with precision and consistency.

At its core, a CNC machine company specializes in using Computer Numerical Control technology, where computers execute pre-programmed sequences of machine control commands to automate and precisely control the machining process. This automation allows for the creation of intricate parts with meticulous dimensions, making CNC machining an indispensable choice for a wide range of industries, including aerospace, medical, automotive, and many more. CNC company offers a comprehensive suite of CNC machining services tailored to meet the diverse needs of its clients.

The seasoned professionals from the CNC company wield the power of CNC machining, a technology that consistently delivers parts characterized by intricate designs and meticulous dimensions. CNC company's machines are programmed with exacting specifications, allowing for the creation of components with near-microscopic precision. This level of accuracy is crucial in industries where even the slightest deviation from specifications can have dire consequences.

Consider the aerospace sector, where aircraft components must meet rigorous standards to ensure safety and reliability. In the medical field, CNC machining plays an important role in producing surgical instruments, prosthetics, and medical devices. Automotive manufacturers also rely heavily on CNC machining for the production of engine components, transmission parts, and chassis components.

What sets CNC machining apart is its ability to maintain this level of precision over high-volume production runs. Plus, the high-precision machines of professional CNC machining companies ensure the consistency of product quality. Whether it's a single prototype or a large-scale production order, CNC machines tirelessly execute their programmed instructions, ensuring that every part is an exact replica of the next.

One of the benefits of partnering with a CNC machine company is that you can choose from a diverse array of materials for your CNC machining needs. CNC machining is not limited by materials, as it can handle various types of plastics, metals, ceramics, carbon fiber, titanium alloy, or even tungsten steel. These materials have different properties and characteristics that make them suitable for different applications and requirements.

For example, plastics are lightweight, flexible, and resistant to corrosion, which are ideal for medical devices, consumer products, or prototypes. Metals are strong, durable, and conductive, which are ideal for automotive or industrial parts. Carbon fiber is stiff, tough, and lightweight, which is ideal for sports equipment or aerospace components. Titanium alloy is corrosion-resistant, biocompatible, and high-temperature resistant, which are ideal for marine applications.

A CNC company like Richconn has the experience and expertise to work with these diverse materials and meet your specific needs with finesse. They can select the appropriate CNC machining type, machine tool, cutting tool, software control, and quality inspection for each material to ensure the optimal quality and performance of your parts. They can also advise you on the best material choice for your project based on your budget and specifications. This reduces the trial-and-error costs and testing time for material selection in projects.

Partnering with a CNC machining company can reduce both time and costs by streamlining production processes and minimizing wastage. CNC companies such as Richconn excel in using CNC technology to automate tasks and optimize production times. They can produce parts faster and more accurately than conventional machining methods, which can take longer and require more manual labor. They can also reduce material waste and energy consumption by using efficient cutting tools and software control.

It can also provide advantages in terms of transportation time and cost savings if CNC companies near me. Not only can you save money on investing in CNC equipment and personnel, but you can also enhance your profitability and competitiveness by lowering production costs and increasing output.

Another benefit of partnering with a CNC company is that you can get flexible solutions for your CNC machining needs.

CNC machining companies understand that every project is unique and has different requirements and objectives. That's why a company like Richconn offers flexible solutions that align with your project's needs. They can customize their CNC machining services according to your specifications, such as material, quantity, tolerance, finish, and delivery date. Therefore, by partnering with CNC machining companies, they can provide you with different options and suggestions to help you achieve your desired results.

When you outsource your CNC machining needs to a professional service provider, you mitigate numerous safety hazards associated with traditional methods. Traditional machining often involves manual handling, increasing the risk of accidents and injuries caused by human error. With a CNC machine company like Richconn, these risks are significantly reduced as automated machines handle intricate tasks. Regular machine maintenance is another key aspect of Richconn's safety measures. By meticulously monitoring and servicing their CNC machines, they prevent malfunctions or breakdowns that could compromise safety and project timelines.

Another benefit of partnering with a CNC company is that you can get instant online quotes for your CNC machining needs. This convenient feature ensures that you can plan your budget effectively and proceed with your CNC machining projects without delays.

That's why Richconn simplifies the quoting process by offering instant online quotes. By getting online services from Richconn, you can save time, money, and hassle. You can also avoid any surprises or hidden fees that might affect your budget planning.

For businesses seeking top-notch CNC machining services, partnering with a reputable CNC company can unlock the full potential of precision engineering. The versatility in materials, coupled with time and cost efficiency, ensures that your projects are not only accurate but also economical. Flexible solutions tailored to your unique needs, along with safety at the forefront, make CNC machining companies like Richconn an invaluable partner. Furthermore, with instant online quotes, you can plan your budget effectively, eliminating any surprises. Ultimately, a CNC company bridges the gap between precision manufacturing excellence and your specific project requirements, providing a seamless path to success.

One Article Tells You What CNC Machining isSeptember 27, 2023The term CNC stands for "Computer Numerical Control" and CNC machining is defined as a subtractive manufacturing process that typically employs computer-controlled and machine tools to remove layers of material from a stock part (known as a blank or workpiece) and produce a custom-designed part.view

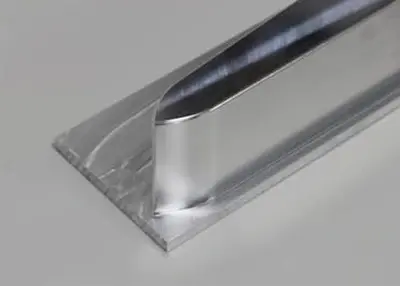

One Article Tells You What CNC Machining isSeptember 27, 2023The term CNC stands for "Computer Numerical Control" and CNC machining is defined as a subtractive manufacturing process that typically employs computer-controlled and machine tools to remove layers of material from a stock part (known as a blank or workpiece) and produce a custom-designed part.view Welding Sheet Metal: How to Weld Sheet Metal? (Techniques & Tips)August 24, 2023Sheet metal welding is the process of using heat and electricity to join thin pieces of metal together. This process is essential for many applications, such as making custom products, repairing damag...view

Welding Sheet Metal: How to Weld Sheet Metal? (Techniques & Tips)August 24, 2023Sheet metal welding is the process of using heat and electricity to join thin pieces of metal together. This process is essential for many applications, such as making custom products, repairing damag...view Richconn 2024 Chinese New Year Holiday NoticeJanuary 2, 2024January 02, 2024Chinese New Year is approaching! We would like to remind you that Richconn will be on holiday to celebrate our Chinese New Year. For your convenience in arranging your project, please ...view

Richconn 2024 Chinese New Year Holiday NoticeJanuary 2, 2024January 02, 2024Chinese New Year is approaching! We would like to remind you that Richconn will be on holiday to celebrate our Chinese New Year. For your convenience in arranging your project, please ...view Snap Fit 101: All You Need to Know About Snap FittingSeptember 19, 2023For a better understanding of snap fitting, we will go through the various types, benefits, and applications of snap fitting and the best tips on designing snap fits.view

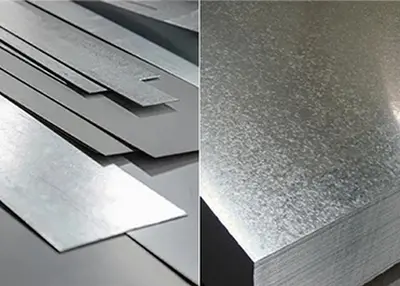

Snap Fit 101: All You Need to Know About Snap FittingSeptember 19, 2023For a better understanding of snap fitting, we will go through the various types, benefits, and applications of snap fitting and the best tips on designing snap fits.view Unveiling the Power of Galvanized Materials: Your Ultimate GuideSeptember 28, 2023Have you ever wondered about the remarkable process that transforms ordinary steel into a corrosion-resistant wonder material? Look no further, as we embark on an enlightening journey to understand the world of galvanization.view

Unveiling the Power of Galvanized Materials: Your Ultimate GuideSeptember 28, 2023Have you ever wondered about the remarkable process that transforms ordinary steel into a corrosion-resistant wonder material? Look no further, as we embark on an enlightening journey to understand the world of galvanization.view Methods and Characteristics of Electrophoretic Metal CoatingJune 17, 2024Methods of Electrophoretic Metal CoatingDue to the different nature of electrophoretic metal coating itself, it is divided into two kinds: anodic electrophoretic metal coating and cathodic electrophor...view

Methods and Characteristics of Electrophoretic Metal CoatingJune 17, 2024Methods of Electrophoretic Metal CoatingDue to the different nature of electrophoretic metal coating itself, it is divided into two kinds: anodic electrophoretic metal coating and cathodic electrophor...view

EN

EN

ru

ru