Artificial Intelligence is having a profound impact on CNC machining services, transforming operations and delivering many benefits. Here are some of the key areas where AI is playing a major role:

One of the most important impacts of AI on CNC manufacturing is the ability to enable continuous production. AI-powered robots can work 24 hours a day without breaks or downtime.

This is especially beneficial for mass production and large manufacturing units, where maintaining a steady pace of production is critical. By removing the constraints of human fatigue and need for rest, AI can achieve previously unattainable levels of productivity. This not only increases overall production, but also ensures faster delivery times.

Safety is the most important issue in any manufacturing environment. Artificial intelligence contributes to a safer work environment by taking over tasks that are dangerous to humans. With the help of machine learning and deep learning systems, machines can handle risky operations without any human involvement. This not only reduces the risk of accidents and injuries, but also allows human workers to focus on tasks that require critical thinking and creativity.

Artificial intelligence and machine learning are particularly well suited for repetitive and recurring tasks. These tasks can be monotonous and prone to human error, but can be automated through AI to improve efficiency and consistency. This type of direct automation is beneficial to manufacturers as it helps to keep production consistent and reduces the likelihood of errors that can lead to waste or rework.

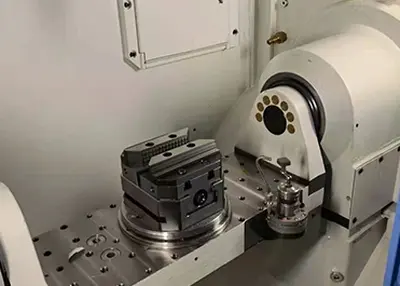

The integration of artificial intelligence with CNC machining has led to an increased demand for this manufacturing method. As AI and machine learning continue to improve the quality, accuracy, and overall performance of CNC machining, more industries are recognizing its potential.

Industries such as automotive, medical, aerospace, military, and marine are increasingly relying on CNC machining to improve efficiency and effectiveness. As a result, we are seeing significant growth in the demand for CNC machining, a trend that is expected to continue as AI technology advances.

Artificial intelligence-driven tools and machines are designed to utilize machine learning and deep learning techniques to enhance their functionality and performance. Unlike traditional machines that follow pre-programmed instructions, AI-powered machines are able to learn from data, adapt to new inputs, and improve their performance over time.

For example, AI-driven machines can respond to voice commands and make decisions for repetitive tasks. They can analyze and process repetitive patterns and respond accordingly, enabling manufacturers to produce high-quality parts that are virtually error-free. This not only improves the accuracy and design-orientation of the parts produced, but also reduces waste and unit costs for manufacturers.

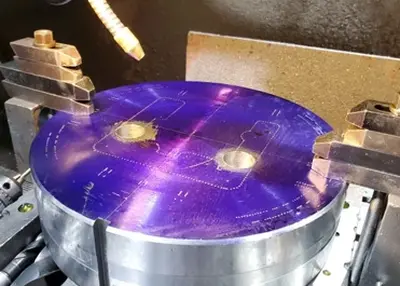

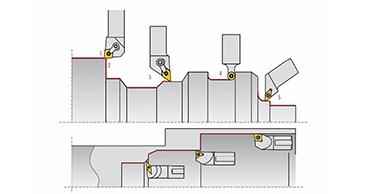

In addition, AI-powered machines are able to handle more complex tasks. For example, tool paths (the way a tool passes through a workpiece) can be optimized through AI data analysis. This allows the machine to adjust the tool path to one that produces the highest level of productivity and the least amount of wear, thus improving the overall efficiency of the machining process.

One of the main advantages that AI machines have over traditional machines is their ability to process large data sets. In the context of CNC machining, this means that AI machines can collect, process, receive, and respond to large amounts of data that can be used to optimize the machining process.

For example, AI can be used to automate the processing of operational data to provide the information needed to make critical decisions and take action. This simplifies the analytics process so that more informed and efficient decisions can be made. Additionally, AI can be used to predict energy consumption during machining processes, providing an effective way to manage energy consumption and achieve long-term sustainability in manufacturing.

The trend of integrating AI into CNC machining is booming, with more and more machine shops incorporating AI into their processes. However, the adoption of AI in CNC machine shops varies depending on a number of factors, including the size of the organization and the nature of its operations.

Despite its many benefits, the adoption of AI in CNC machining is not without its challenges. For one, it requires a significant investment in time and money. Determining whether the long-term use of AI technology will benefit a particular CNC machining operation can be a complex process that requires careful analysis and planning.

Not all CNC machine shops will be able to take full advantage of AI. For example, a small CNC machine shop may fulfill a niche market but not feel the need to develop their skills. Or, their limited processes may lack the ability to capitalize on the benefits of automation. If their equipment and software systems are not ready for automation, the complexity of a fully automated system may become a burden.

Differences between small and large CNC machine shops adopting AI

CNC machine shop adoption of AI also varies by organization size. Medium to large organizations are typically better positioned to adopt AI in the future. When you combine today's labor shortages (and skills gaps) with the technology revolution, it's clear that AI is elevating the importance of experts who program, operate, and truly understand automated CNC machines.

Adopting AI improves efficiencies, enabling industry engineers in these organizations to perform more value-added tasks, expand quality control efforts and create smarter operations. This not only improves the overall productivity and efficiency of these organizations, but also allows them to better meet the growing demands of CNC machining.

As AI technology advances, it is likely that AI will become advanced enough to connect to design software and automatically modify designs to improve results. Derivative design is an iterative design process that automatically optimizes designs for use with software such as Autodesk Dreamcatcher and links directly to additive manufacturing (3D printing) or subtractive manufacturing (CNC machining) processes.

The future of CNC machining will almost certainly be a more connected one, with the entire manufacturing process connected through cloud computing, AI optimization, diagnostics and fault correction. However, for the foreseeable future, human CNC machinists will still be needed to operate computers, load designs, oversee the process, and correct any faults.

The overall impact of artificial intelligence and machine learning on CNC machining operations is profound. While there are still challenges to overcome, the potential benefits of these technologies are immense. As we continue to explore and utilize the power of AI and machine learning, it appears that the future of CNC machining will be one of increased efficiency, productivity, and innovation. Finding the right partner to utilize this technology is necessary to ensure that your company doesn't fall behind the curve.

7 Applications of CNC Machining Medical Parts ManufacturingOctober 25, 2023The medical industry is constantly innovating and finding ways to improve the quality of life and outcomes for patients. One such technology, computer numerical control (CNC) machining, has become a revolutionary tool in medical hardware manufacturing. In this rapidly evolving field, CNC machines not only provide a high level of precision and accuracy, but are also able to cope with a wide range of materials and complex geometries.view

7 Applications of CNC Machining Medical Parts ManufacturingOctober 25, 2023The medical industry is constantly innovating and finding ways to improve the quality of life and outcomes for patients. One such technology, computer numerical control (CNC) machining, has become a revolutionary tool in medical hardware manufacturing. In this rapidly evolving field, CNC machines not only provide a high level of precision and accuracy, but are also able to cope with a wide range of materials and complex geometries.view Machining Tolerances 101: A Complete Guide to CNC Machining TolerancesApril 24, 2024No CNC machine is 100% accurate. That’s the reason why you need to leave spaces for errors in every design of your project. This is where the CNC machining tolerances come in.view

Machining Tolerances 101: A Complete Guide to CNC Machining TolerancesApril 24, 2024No CNC machine is 100% accurate. That’s the reason why you need to leave spaces for errors in every design of your project. This is where the CNC machining tolerances come in.view How Many Fasteners Are Needed in the Construction Machinery Sector?October 27, 2023Fasteners as commonly used parts, you should not be unfamiliar, today Richconn from the classification of fasteners, the identification and inspection of threads, bolts, screws and studs of the material requirements, heat treatment requirements and mechanical performance requirements, the types of steel bolts and the construction of the four aspects of the introduction.view

How Many Fasteners Are Needed in the Construction Machinery Sector?October 27, 2023Fasteners as commonly used parts, you should not be unfamiliar, today Richconn from the classification of fasteners, the identification and inspection of threads, bolts, screws and studs of the material requirements, heat treatment requirements and mechanical performance requirements, the types of steel bolts and the construction of the four aspects of the introduction.view Basic of Gear Manufacturing: A Guide to Learn about Gear Production ProcessesAugust 29, 2023There is no single process for manufacturing gear because several processes are required based on the type and application. The gears need to be in absolutely perfect condition to adapt to strenuous c...view

Basic of Gear Manufacturing: A Guide to Learn about Gear Production ProcessesAugust 29, 2023There is no single process for manufacturing gear because several processes are required based on the type and application. The gears need to be in absolutely perfect condition to adapt to strenuous c...view What Is Extruded Aluminum And How Does It Work?February 1, 2024Aluminum extrusion has been increasingly popular in making many types of products. What is aluminum extrusion? How does it work? Read this article about the extrusion process.view

What Is Extruded Aluminum And How Does It Work?February 1, 2024Aluminum extrusion has been increasingly popular in making many types of products. What is aluminum extrusion? How does it work? Read this article about the extrusion process.view American Scientific Research Has Found A Fast And Effective Processing Method Of Low-Temperature Titanium AlloyMay 30, 2022Titanium is widely used in the aerospace industry because of its high strength and low density. However, compared with steel, aluminum, and other metals, its hot processing cost is high and it is at a...view

American Scientific Research Has Found A Fast And Effective Processing Method Of Low-Temperature Titanium AlloyMay 30, 2022Titanium is widely used in the aerospace industry because of its high strength and low density. However, compared with steel, aluminum, and other metals, its hot processing cost is high and it is at a...view

EN

EN

ru

ru