Titanium alloys are a variety of alloy metals made of titanium and other metals, which are relatively scarce and expensive; titanium alloys are characterized by high strength, light weight, corrosion resistance and high temperature resistance, and can be used in a variety of fine chemicals, which are mainly used in the automotive industry, aerospace, nuclear industry, chemical and petrochemical industries, dentistry and medical restoration and other fields.

The surface treatment method of titanium alloy is not only to increase the aesthetics of the surface, but more importantly to improve the surface and adaptability of titanium alloy through these surface treatment and modification processes. Titanium alloy materials mainly have the following kinds of surface treatment processes:

Plating on the surface of titanium alloy, mainly nickel, gold, copper, etc., the purpose is to improve the titanium alloy adhesion ability, electrical conductivity and brazing; but plating also exists in some of the problems, that is, the poor bonding between the plating layer and the substrate, so we need to carry out pre-treatment before the surface treatment:

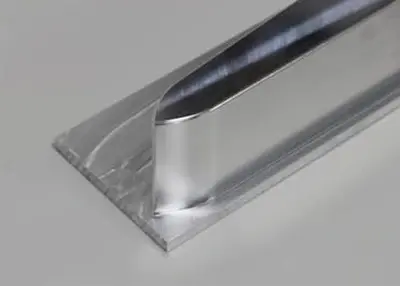

① sandblasting: it can remove the passivation layer on the surface of titanium alloy, remove all the dirt such as rust skin on the surface of the workpiece, and roughen the surface, so as to improve the bonding between the workpiece and the plating layer.

② Pickling: it can remove the oxide skin and other dirt on the metal surface, so as to improve the performance of the metal surface and prevent corrosion, oxidation and abrasion, etc.; however, if the pickling is not up to standard, the subsequent processing will be greatly affected, so the process of pickling must be handled in strict accordance with the requirements of the process.

If you need metal plating services, you can contact Richconn, we have 16 years of experience in this area.

Surface relying on the arc discharge generated by the role of instantaneous high temperature and high pressure, the growth of oxide ceramic film of the new technology. Micro-arc oxidation process has a strong processing capacity, can change the process parameters to obtain different characteristics of the oxide film layer to meet the needs of different purposes, can be very good to improve the hardness, improve the bonding force, improve the surface of the titanium alloy wear resistance, corrosion resistance, thermal shock resistance and insulation properties, and is a green and non-polluting surface treatment process, has a very broad market prospects and research value.

Coloring to improve the surface properties of titanium alloy materials at the same time, but also according to customer demand for products to form a different color, to achieve the appearance of parts of the decorative. Titanium alloy surface coloring process includes: atmospheric oxidation, anodic oxidation, chemical treatment, micro-arc oxidation, at present, anodizing service is the most commonly used coloring method for titanium alloy.

Blackening is a common means of chemical surface treatment, the principle is to produce a layer of oxidized film on the surface of the metal, so that the metal parts and the air completely isolated, so as to achieve the purpose of rust prevention, blackening treatment can also increase the surface gloss of the metal parts to make it more beautiful, and can also reduce some of the deformation caused by the inner or outer force on the workpiece, in terms of black oxide coating services. Richconn has rich experience in black oxide coating services.

In order to remove surface burrs, so that the role of the surface bright. Mainly divided into rough polishing, medium polishing, fine polishing, precision polishing. Currently on the market some of the modern jewelry by the young people's favorite, it is after the high polish, silk, matte and other surface treatment processes, and will not fade like paint, compared to other metal jewelry is more hard.

Thermal spraying is the use of a heat source will be sprayed material heated to a molten or semi-molten state, with a high-speed airflow will be atomized and sprayed onto the surface of the substrate, so that the basic formation of a layer of solid coating; thermal spraying process is highly efficient, easy and flexible operation, can be coated with a wider range of coating materials, is the surface protection and surface enhancement of the new technology.

The Difference Between Precision Sheet Metal Fabrication and Ordinary Sheet Metal FabricationSeptember 27, 2023In recent years, as the market demand for precision of sheet metal parts has increased, precision sheet metal fabrication has also begun to enter the center stage of the sheet metal industry.view

The Difference Between Precision Sheet Metal Fabrication and Ordinary Sheet Metal FabricationSeptember 27, 2023In recent years, as the market demand for precision of sheet metal parts has increased, precision sheet metal fabrication has also begun to enter the center stage of the sheet metal industry.view What is a CNC machine? The Precision Way to Modern ManufacturingSeptember 21, 2023CNC machine stands for Computer Numerical Control, which is a manufacturing process that controls the movement of a tool or machine through a computer program.view

What is a CNC machine? The Precision Way to Modern ManufacturingSeptember 21, 2023CNC machine stands for Computer Numerical Control, which is a manufacturing process that controls the movement of a tool or machine through a computer program.view Welding Sheet Metal: How to Weld Sheet Metal? (Techniques & Tips)August 24, 2023Sheet metal welding is the process of using heat and electricity to join thin pieces of metal together. This process is essential for many applications, such as making custom products, repairing damag...view

Welding Sheet Metal: How to Weld Sheet Metal? (Techniques & Tips)August 24, 2023Sheet metal welding is the process of using heat and electricity to join thin pieces of metal together. This process is essential for many applications, such as making custom products, repairing damag...view Common Cheap CNC Material - An Overview of PlasticsJune 17, 2024Cheap CNC Material——ABSABS is one of the most common cheap CNC material, with good mechanical properties, excellent impact strength, high heat resistance, and good machinability.ABS has a low densit...view

Common Cheap CNC Material - An Overview of PlasticsJune 17, 2024Cheap CNC Material——ABSABS is one of the most common cheap CNC material, with good mechanical properties, excellent impact strength, high heat resistance, and good machinability.ABS has a low densit...view Chip Types Of Automatic Gear Production Line And Application Scope Of Chip Treatment SystemApril 12, 2022This paper studies the characteristics of different kinds of chips produced in the process of gear machining and gives the corresponding treatment scheme, which provides technical support for the auto...view

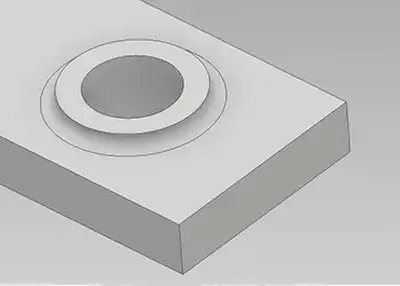

Chip Types Of Automatic Gear Production Line And Application Scope Of Chip Treatment SystemApril 12, 2022This paper studies the characteristics of different kinds of chips produced in the process of gear machining and gives the corresponding treatment scheme, which provides technical support for the auto...view What is a Machined Boss: A Comprehensive GuideNovember 8, 2023In the world of precision engineering, the term machined boss may not be a household name, but it is undoubtedly a crucial element that underpins countless industries. Whether you're a novice looking to expand your knowledge or a seasoned professional seeking in-depth insights, this article will serve as your comprehensive guide to understanding what a machined boss is, how it works, and why it matters.view

What is a Machined Boss: A Comprehensive GuideNovember 8, 2023In the world of precision engineering, the term machined boss may not be a household name, but it is undoubtedly a crucial element that underpins countless industries. Whether you're a novice looking to expand your knowledge or a seasoned professional seeking in-depth insights, this article will serve as your comprehensive guide to understanding what a machined boss is, how it works, and why it matters.view

EN

EN

ru

ru