In the intricate tapestry of mechanical engineering, machined gears stand as the unsung heroes, translating rotational motion with unparalleled precision. These gears are meticulously crafted to meet the demanding requirements of various industries, ensuring seamless operation in complex machinery.

Machined gears, by definition, are precision-engineered components with teeth that mesh together to transmit motion and power. The manufacturing process involves cutting, shaping, and finishing to exact specifications, often with the aid of advanced CNC machining techniques. Richconn's commitment to excellence in this realm ensures gears that not only meet but exceed the stringent standards of modern mechanical systems.

Let's dive deeper into the defining characteristics of machined gears, exploring aspects such as tooth profiles, pitch circles, and the crucial role these features play in achieving optimal performance. Below is a table illustrating the typical characteristics of machined gears:

| Characteristic | Description |

|---|---|

| Tooth Profile | Involute, Cycloidal, or Customized Profiles |

| Pitch Circle Diameter | Determined by the Number of Teeth and Module |

| Precision Tolerance | Measured in Microns for High Accuracy |

| Surface Finish | Smooth Finish to Reduce Friction and Wear |

Understanding these characteristics is paramount for both manufacturers and end-users, ensuring the proper selection and application of machined gears in diverse settings.

The heart of machined gear excellence lies in the manufacturing process, where raw materials are transformed into precision-engineered components. CNC machining takes center stage, enabling the creation of gears with unparalleled accuracy and repeatability.

Explore the specific CNC machining techniques employed by Richconn to ensure the highest quality machined gears. This includes multi-axis milling, gear hobbing, and grinding, each contributing to the overall precision and durability of the final product.

The choice of materials is a critical factor in the performance of machined gears. Richconn's expertise lies in selecting materials with the right balance of strength, hardness, and durability. Common materials include alloy steels, stainless steels, and specialized alloys for demanding applications.

Maintaining the highest standards of quality is non-negotiable in machined gear manufacturing. Richconn employs advanced inspection tools such as coordinate measuring machines (CMM) and optical comparators to ensure every gear meets the specified tolerances.

Below is a table illustrating the materials commonly used in machined gear manufacturing:

| Material | Properties | Common Applications |

|---|---|---|

| Alloy Steel | High Strength, Good Wear Resistance | Automotive, Industrial Machinery |

Machined gears serve as the backbone of diverse industries, facilitating smooth machinery operation in various applications. Understanding their widespread use provides insights into the versatility and significance of these precision components.

In the automotive sector, machined gears are integral to the functioning of transmissions and differentials. They ensure efficient power transfer, contributing to the overall performance and reliability of vehicles. Richconn's expertise in producing gears with tight tolerances and optimal durability makes them a trusted partner for automotive manufacturers.

The aerospace industry relies on machined gears for critical applications such as aircraft engines and landing gear systems. The precision and reliability of machined gears are paramount in ensuring the safety and efficiency of aerospace operations. Richconn's commitment to meeting aerospace-grade standards positions them as a preferred supplier in this high-stakes sector.

In the realm of medical equipment, machined gears play a vital role in devices like diagnostic machinery and robotic surgical systems. The precision and smooth operation of these gears are crucial for maintaining the accuracy of medical procedures. Richconn's dedication to producing gears with exceptional precision aligns with the stringent requirements of the medical field.

Machined gears find extensive use in various industrial machinery, from manufacturing equipment to heavy-duty machinery. They facilitate the synchronized movement of components, ensuring optimal efficiency in industrial processes. Richconn's customized solutions cater to the diverse needs of industrial clients, providing gears that withstand the rigors of demanding applications.

Even in the world of consumer electronics, machined gears are employed in devices like printers and cameras. The compact size and high precision of these gears contribute to the miniaturization and efficiency of electronic gadgets. Richconn's ability to tailor gears for specific electronic applications positions them as a valuable partner in the fast-paced world of consumer technology.

The performance of machined gears is defined by a set of characteristics that distinguish them from other gear types. Understanding these features is crucial for both manufacturers and end-users seeking optimal performance in their machinery.

Machined gears, crafted from high-quality materials and subjected to rigorous manufacturing processes, exhibit exceptional durability. They withstand heavy loads, continuous operation, and harsh environmental conditions, ensuring a long service life.

Precision is the hallmark of machined gears. The use of CNC machining techniques allows for the creation of gears with tight tolerances, minimizing backlash and ensuring smooth and accurate motion transmission. Richconn's commitment to precision is evident in every gear produced, contributing to the reliability of diverse mechanical systems.

The meshing of machined gears is designed to minimize noise during operation. The smooth tooth profiles and precise engagement reduce vibration and noise levels, making them suitable for applications where quiet operation is essential, such as in consumer electronics and high-end machinery.

Machined gears excel in efficiently transmitting power from one component to another. Whether in a car's transmission or an industrial gearbox, these gears ensure minimal power loss, contributing to the overall energy efficiency of mechanical systems.

The materials used in machined gears, coupled with precision manufacturing, make them adaptable to diverse environments. They can withstand temperature variations, corrosive conditions, and heavy loads, making them suitable for applications ranging from automotive to aerospace.

One of the strengths of machined gears lies in their versatility and the ability to be customized for specific applications. Richconn collaborates closely with clients to understand their unique requirements, providing tailored solutions that address the specific challenges of each application.

Staying abreast of market trends and technological advancements is imperative in the ever-evolving landscape of machined gear manufacturing. Understanding the current dynamics allows manufacturers and end-users to make informed decisions and stay ahead of the competition.

The global demand for precision components, including machined gears, continues to rise across industries. This trend is driven by the need for enhanced efficiency, reliability, and performance in machinery. Richconn's proactive approach to meeting this demand positions them as a reliable partner for clients seeking precision-engineered gears.

The field of CNC machining, integral to the production of machined gears, is witnessing rapid advancements. Innovations in tooling, automation, and programming are enhancing the efficiency and capabilities of CNC machines. Richconn's commitment to adopting cutting-edge technologies ensures that their manufacturing processes remain at the forefront of industry standards.

As sustainability becomes a focal point in manufacturing, the machined gear industry is witnessing a shift towards sustainable practices. This includes the use of eco-friendly materials, energy-efficient manufacturing processes, and recycling initiatives. Richconn's dedication to environmental responsibility aligns with this trend, providing clients with sustainable solutions without compromising on quality.

The integration of Internet of Things (IoT) technologies and Industry 4.0 principles is transforming the manufacturing landscape. In the context of machined gears, this involves real-time monitoring, predictive maintenance, and data-driven insights. Richconn's readiness to embrace smart manufacturing practices ensures that their clients benefit from the advantages offered by the latest technological trends.

A thorough comparative analysis between machined gears and alternative gear types provides valuable insights for decision-makers. Understanding the strengths and weaknesses of each option is essential for choosing the most suitable gear for a particular application.

Crafted with precision through CNC machining.

Suitable for applications requiring high precision and durability.

Customizable for specific requirements.

Higher initial costs offset by long-term reliability.

Mass-produced using molds and injection molding.

Cost-effective for large-scale production.

Limited precision compared to machined gears.

May be suitable for applications with lower precision requirements.

Precision-engineered through CNC machining.

Ideal for applications requiring high precision and reliability.

Well-suited for low to medium volume production.

Offers customization options for specific needs.

Produced through stamping and forming processes.

Cost-effective for high-volume production.

Limited precision compared to machined gears.

Suitable for applications where precision is not a critical factor.

Crafted with precision using CNC machining techniques.

Offers high precision and durability.

Suitable for a wide range of applications.

Ideal for low to medium volume production.

Fabricated through powder metallurgy.

Cost-effective for high-volume production.

Limited precision compared to machined gears.

Suitable for applications with lower precision requirements.

This comparative analysis empowers decision-makers with the knowledge needed to select the most suitable gear type for their specific applications. While each type has its advantages, machined gears excel in scenarios where precision, durability, and customization are paramount.

In the competitive landscape of machined gear manufacturing, Richconn stands out as a beacon of excellence. Their success story is a testament to their unwavering commitment to quality, innovation, and customer satisfaction.

Richconn's success in machined gear manufacturing is underpinned by their technological expertise. They invest in state-of-the-art CNC machining equipment and stay abreast of the latest advancements in the field. This commitment ensures that every gear produced reflects the pinnacle of technological excellence.

Quality is at the forefront of Richconn's operations. Rigorous quality control measures, including advanced inspection tools and protocols, are implemented at every stage of the manufacturing process. This dedication to quality assurance guarantees that every machined gear bearing the Richconn name meets and exceeds industry standards.

The ultimate measure of success lies in customer satisfaction, and Richconn takes pride in fostering long-lasting relationships with their clients. By understanding the unique needs of each customer and providing tailored solutions, Richconn has become a trusted partner in the success of diverse industries.

One of Richconn's distinguishing factors is their commitment to innovation in customization. They collaborate closely with clients, offering tailored solutions that address specific challenges and requirements. This level of customization ensures that every machined gear produced by Richconn is precisely suited to its intended application.

Richconn's success is not only rooted in their current achievements but also in their adaptability to market trends. By staying ahead of industry shifts, technological advancements, and sustainability practices, Richconn remains a forward-thinking force in the dynamic landscape of machined gear manufacturing.

The culmination of technological expertise, quality assurance, customer satisfaction, and innovation has positioned Richconn as a leader in the machined gear manufacturing industry. Their success story serves as an inspiration for aspiring manufacturers and a testament to the enduring value of precision, excellence, and integrity.

The journey into the precision world of machined gears with Richconn unveils not just gears but a commitment to excellence, innovation, and customer satisfaction. Whether you are navigating the intricacies of gear characteristics, exploring applications across industries, understanding performance features, or contemplating the future trends in gear manufacturing, Richconn stands ready as your trusted partner in precision engineering. Your path to mechanical excellence continues with Richconn, where every gear tells a story of precision, reliability, and success.

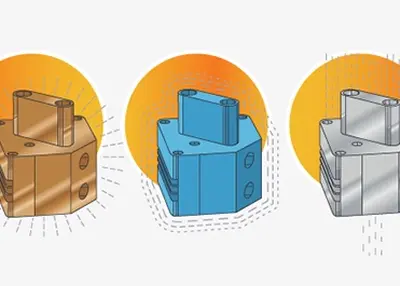

Narrowing Down Material Options For CNC Machining.October 17, 2023Choice is good. In most cases, the greater the selection, the greater the chance of finding just the right thing. But a large selection also means that finding the perfect material becomes more complicated.view

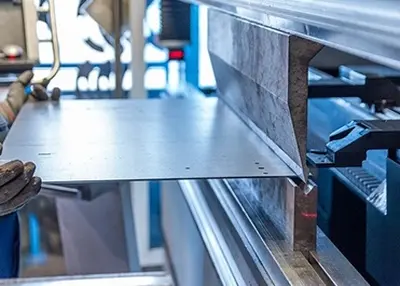

Narrowing Down Material Options For CNC Machining.October 17, 2023Choice is good. In most cases, the greater the selection, the greater the chance of finding just the right thing. But a large selection also means that finding the perfect material becomes more complicated.view 5 Bending and Forming Methods for Sheet MetalDecember 4, 2023Sheet metal refers to a process used to manufacture a variety of metal products, which involves processing sheet metal into the desired shape and size by cutting, stamping, bending, and welding.view

5 Bending and Forming Methods for Sheet MetalDecember 4, 2023Sheet metal refers to a process used to manufacture a variety of metal products, which involves processing sheet metal into the desired shape and size by cutting, stamping, bending, and welding.view What Are the General Types of Measurement Methods for Machining Accuracy of Machine Parts?October 27, 2023Machining accuracy is the actual size, shape, position of the surface of the machined part three kinds of geometric parameters and drawings required by the ideal degree of compliance with the geometric parameters.view

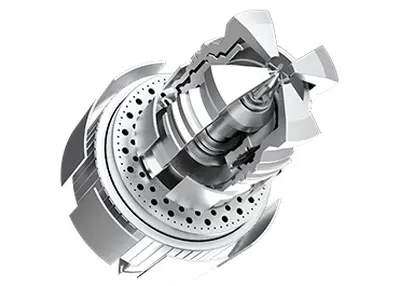

What Are the General Types of Measurement Methods for Machining Accuracy of Machine Parts?October 27, 2023Machining accuracy is the actual size, shape, position of the surface of the machined part three kinds of geometric parameters and drawings required by the ideal degree of compliance with the geometric parameters.view Unleashing Precision: Richconn's CNC Machined Steel ExcellenceNovember 10, 2023Welcome to the realm of precision and durability, where machined steel takes center stage. In this comprehensive exploration, we'll navigate through the intricacies of machined steel, unveil its diverse applications, compare various types, delve into performance metrics, examine Richconn's CNC machining advantages, and provide essential knowledge on mechanical machining.view

Unleashing Precision: Richconn's CNC Machined Steel ExcellenceNovember 10, 2023Welcome to the realm of precision and durability, where machined steel takes center stage. In this comprehensive exploration, we'll navigate through the intricacies of machined steel, unveil its diverse applications, compare various types, delve into performance metrics, examine Richconn's CNC machining advantages, and provide essential knowledge on mechanical machining.view Exploring Chameleon PVD Coating in DesignJanuary 5, 2024The world of design is constantly evolving, with new techniques and materials pushing boundaries and inspiring creativity. One such innovation that has revolutionized the design industry is Chameleon ...view

Exploring Chameleon PVD Coating in DesignJanuary 5, 2024The world of design is constantly evolving, with new techniques and materials pushing boundaries and inspiring creativity. One such innovation that has revolutionized the design industry is Chameleon ...view CNC Control Systems: Unraveling the Core of Computer Numerical ControlNovember 3, 2023Are you ready to delve into the heart of modern manufacturing technology? Welcome to the world of CNC Control Systems, where precision and automation meet to revolutionize industries.view

CNC Control Systems: Unraveling the Core of Computer Numerical ControlNovember 3, 2023Are you ready to delve into the heart of modern manufacturing technology? Welcome to the world of CNC Control Systems, where precision and automation meet to revolutionize industries.view