Reaming is an important process in CNC machining services, and its main purpose is to join parts or components so that they can rotate or oscillate relative to each other and move at a specific angle or direction. Reaming has a wide range of applications in the manufacturing industry and is capable of fulfilling a wide range of functions and needs, from simple connections to complex mechanisms. In this article, we will discuss in detail the purpose of reaming and its application in different fields.

The basic purpose of reaming is to achieve relative motion between two or more components, which is usually rotational or oscillatory, depending on the design and use of the reamed hole. The following are the main purposes of reaming:

Joining members: reaming allows two or more members to be joined together to form an integral unit. These members can be made of metal, plastic, wood or other materials, and by connecting them through a reamed hole, they can move relatively freely while maintaining a certain degree of stability.

Realization of rotational movement: reaming allows the members to rotate about an axis. This rotary motion can be continuous or restricted within certain limits, depending on the design of the reamed hole. Rotary motion is used in a wide variety of mechanical devices, such as the opening and closing of doors and the movement of pistons in engines.

Realization of oscillating motion: In addition to rotary motion, reamed holes can also realize oscillating motion, also known as swinging. This movement allows the member to swing at an angle in a plane, which is very common in applications such as doors, suspensions and robotic arms.

Adjustment of angle and orientation: Reamed holes can also be used to adjust the angle and orientation between members. By designing different types of reamed holes, different degrees of adjustment can be achieved to meet specific needs. This is very useful in various engineering and manufacturing fields.

Transmitting forces and torques: Reamed holes not only enable movement, but also transmit forces and torques. This means that reamed holes are not only used for connecting components, but also for transmitting power and torque, e.g. in mechanical drive systems.

Realization of specific working mechanisms: Reamings can also be used to realize specific working mechanisms, for example to allow a robot arm to move in multiple degrees of freedom, or to allow a vehicle's suspension system to adapt to different road conditions. Through cleverly designed reamed holes, a variety of complex mechanical movements can be realized.

There are many types of reamed holes, each with a different design and application. The following are some common types of reamed holes:

Fixed Reaming: Fixed reaming is the simplest type and is usually used to connect two members and allow them to rotate around an axis. This type of reaming does not allow for any other movement of the members relative to the axis.

Oscillating ream: An oscillating ream allows the members to swing in one plane, but does not allow rotation about an axis. This type of reaming is commonly used in applications such as doors and suspension devices.

Swivel Ream: A swivel ream allows the member to rotate about an axis, but does not allow for oscillation. This type of reaming is commonly used in engine piston movement and mechanical rotation devices.

Ball Reaming: Ball reaming is a complex type of reaming that allows the member to move freely in three dimensions, including rotation and oscillation. This type of reaming is commonly used in robotics and multi-degree-of-freedom mechanisms.

Link reamings: Link reamings are used to connect two components and allow them to rotate relative to each other within a specific angle range. This type of hinge is commonly used in vehicle suspension systems and door hinges.

Hinge Hinge: The hinge hinge is a special type of swing hinge, often used in applications such as doors, boxes and book covers, which allows the member to rotate about an axis and swing in a plane.

Oscillating-Rotating Ream: This type of reaming allows the member to oscillate in one plane and rotate about an axis. This is useful in some robotic arms and camera mounts.

Reaming has a wide range of applications in various engineering fields and manufacturing industries. The following are examples of some of the major application areas:

Automotive industry: reamed holes are used in automobile suspension systems, steering mechanisms, door hinges and seat adjustment mechanisms to achieve a variety of movements and adjustments.

Mechanical Manufacturing: In mechanical manufacturing, reaming is used to create a variety of mechanisms and drivelines, such as linkage, crank and slider mechanisms.

Aerospace industry: Reamings in aircraft, spacecraft and satellites are used to control rudders, rudder wings and telescopic mechanisms in aerospace vehicles.

Building and construction engineering: Reamings in doors, windows, staircases and various building structures are used to realize opening and closing movements and to adjust angles.

Electronics: Reaming is used for screen holders in laptops, cell phones and tablets, as well as adjustment mechanisms for keyboards and monitors.

Robotics: Reaming plays a key role in robotics, allowing robots to perform multiple degrees of freedom and complex maneuvers.

Medical devices: Reamings in medical devices are used to adjust surgical beds, diagnostic equipment and rehabilitation devices to suit different patient needs.

Furniture Manufacturing: Reaming is commonly used in the manufacture of furniture such as chairs, tables, folding beds and furniture doors to allow for a variety of movement and folding functions.

Agricultural machinery: Reaming is used in agricultural machinery to control the movement of harvesters, cultivators and agricultural equipment.

Construction Machinery: Reamed holes in construction machinery are used in equipment such as excavators, loaders and cranes to realize various engineering operations.

Amusement equipment: Reamings in amusement equipment such as playground equipment, Ferris wheels and roller coasters are used to realize various dynamic and rotational movements.

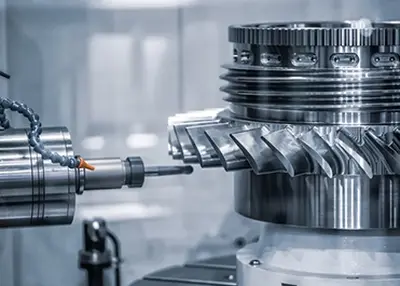

Reamer and reaming are two related concepts in the field of machining and metalworking. Both are essential for achieving precise and smooth holes in Both are essential for achieving precise and smooth holes in workpieces, but they refer to different aspects of the process.

Reaming is a machining process used to refine and enlarge a previously drilled, bored, or cast hole to achieve a more accurate size, improved surface finish, and tighter tolerance. The primary purpose of reaming is to ensure that the hole meets specific dimensional and geometric requirements.

Key points about reaming.

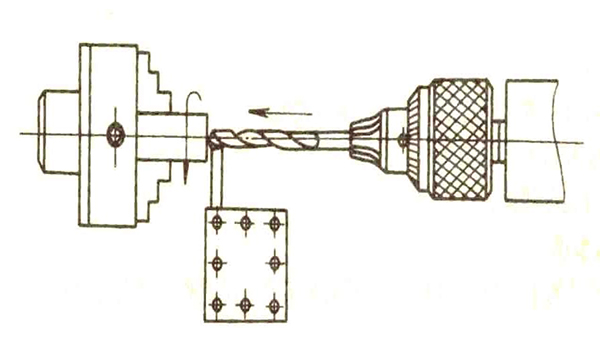

A. Process. A. Process. Reaming is performed using a tool called a reamer, which has multiple cutting edges and is typically designed with precise dimensions and angles. The reamer is inserted into the pre-existing hole, and the tool is rotated, often with the help of a machine or hand-operated equipment.

B. B. Objective. The primary objective of reaming is to make the hole smoother, more precise, and to bring it into compliance with tight tolerances. Reaming can also be used to create specific surface finishes, such as a fine or super-finish.

C. Material Removal. During reaming, a small amount of material is removed from the hole's inner surface. The amount of material removed depends on the reamer's design and the desired hole specifications.

D. D. Accuracy. Reaming is used when high levels of accuracy and precision are required. It can be used to achieve tight tolerances and ensure that parts fit together correctly.

E. E. Types of Reamers. There are various types of reamers, including hand reamers, machine reamers, chucking reamers, and adjustable reamers, each designed for specific applications and precision requirements.

Applications of Reaming.

Applications of Reaming: Metalworking. Reaming is extensively used in the metalworking industry, especially in the manufacturing of engine components, aerospace parts, and precision instruments.

Automotive: Reaming is employed in the automotive industry. Reaming is employed in the automotive sector for creating precise holes in engine blocks, cylinder heads, and transmission components.

Tool and Die Making: Reaming is crucial in the production of engine blocks, cylinder heads, and transmission components. Reaming is crucial in the production of molds, dies, and other tooling components where precision is paramount.

Firearms Manufacturing. The firearm industry relies on reaming to achieve the correct bore dimensions in gun barrels for accuracy and safety.

Aerospace: In aerospace applications, reaming to achieve the correct bore dimensions in gun barrels for accuracy and safety. In aerospace applications, reaming is used to create accurately sized and finished holes in aircraft structural components.

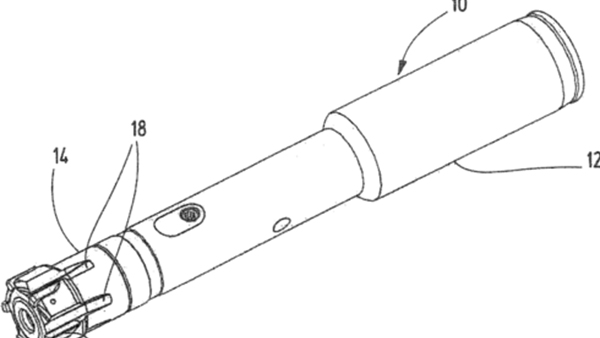

A reamer is a cutting tool with multiple flutes and cutting edges designed to remove a small amount of material from the inner surface of a hole to improve its accuracy, size, and surface finish. The reamer's primary function is to perform the reaming process effectively.

Key points about reamers.

A. Design. A. Design. Reamers are precision tools with specific dimensions and geometries. They come in various sizes and styles, including straight-flute reamers, spiral-flute reamers, and tapered reamers, each suited for different applications.

B. Construction. Reamers are typically made from high-speed steel (HSS), carbide, or other hard materials to withstand the rigors of the machining process.

C. C. Types. There are different types of reamers based on their applications, such as hand reamers, machine reamers, and adjustable reamers.

D. Cutting Action. Cutting Action. Reamers have sharp cutting edges that remove material gradually and uniformly from the hole's inner surface.

E. E. Precision: Reamers are manufactured to tight tolerances. Reamers are manufactured to tight tolerances, ensuring that they create accurate and consistent holes.

F. Application. F. Application. Reamers are used exclusively for the reaming process. They are chosen based on factors such as hole size, material, and desired finish.

G. Maintenance. Proper maintenance and sharpening of reamers are essential to ensure their continued effectiveness and longevity.

Definition. A reamer is a cutting tool used in the reaming process, while reaming is the machining process itself.

Function. The primary function of a reamer is to remove material from the inner surface of a hole to improve its accuracy, size, and finish. Reaming, on the other hand, refers to the entire process of using a reamer to achieve these objectives.

Tool vs. Process. A reamer is a tool, whereas reaming is a machining process that involves the use of a reamer.

Material Removal: Reamers remove material from the hole. Reamers remove material from the hole's inner surface, while reaming describes the action of using a reamer to perform this material removal.

Precision. Both reamer and reaming are associated with precision, as their primary purpose is to achieve accurate hole dimensions and surface finishes.

Types: Reaming includes various types of reamers designed for specific applications, while reamers themselves come in different styles and configurations based on their intended use. Types: Reaming includes various types of reamers designed for specific applications while reamers themselves come in different styles and configurations based on their intended use.

Applications: Reaming is a machining operation used in a wide range of industries, while reamers are the specialized tools employed for this purpose.

A pipe reamer is a specialized cutting tool used in pipe machining, which plays an important role in pipe Cnc Plastic Machining manufacturing, installation and maintenance. The main uses of pipe reamers cover a wide range of sectors including manufacturing, construction, the oil and gas industry, and water and heating systems.

A pipe reamer is a cutting tool, usually with multiple cutting edges, that is used to cut, trim and machine the ends or edges of pipes. These edges are capable of chipping away the outer material of the pipe to give the pipe end the desired shape and smoothness. Pipe reamers are usually made of sturdy materials to ensure their durability in pipeline processing.

Pipe reamers work similarly to other reamers in that they gradually remove material from the end of the pipe by cutting or planing to achieve the desired size and shape. The cutting edge of a pipe reamer is designed with a specific angle and geometry to ensure accuracy and smoothness of the cutting process. When using a pipe reamer, it usually needs to be inserted into the end of the pipe and cut by rotating or applying force.

Pipe reamers have a wide range of uses in various fields and their main role is to trim, process and manufacture pipes to meet different needs and standards. The following are the main uses of pipe reamers:

Pipe reamers play a key role in the manufacturing process of pipes. When manufacturing pipelines, it is often necessary to trim the end of the pipeline to the desired shape and size to ensure that it meets engineering requirements and standards. Pipe reamers are used to chip away irregularities or excess material from the end of a pipe to give it the correct shape and smooth internal and external surfaces. This helps to ensure that the process of joining and installing the pipe runs smoothly.

During pipeline installation and maintenance, it is often necessary to trim the ends of pipelines to ensure that they are flat, smooth and meet connection requirements. Pipe reamers are used to trim pipe ends to remove any damage, corrosion or irregularities that may exist. This is important for pipe connections, sealing and fluid transfer.

An important use of pipe reamers is to prepare the ends of pipes for joining. In piping systems, it is often necessary to connect piping to valves, flanges, fittings or other piping segments. Pipe reamers are used to dress pipe ends to ensure that the connection area has a flat surface for a reliable seal and connection.

During the operation of a piping system, piping may be subject to damage, corrosion, or other forms of wear and tear. During pipeline maintenance and repair, pipe reamers can be used to trim damaged portions of the pipeline to restore its function and extend its service life. This saves on repair costs and reduces downtime of the piping system.

During pipe welding, it is often necessary to prepare the end of the pipe into the proper shape for welding. Pipe reamers are used to chip away any unevenness or oxidized layers at the end of the pipe to ensure the quality and strength of the welded joint. This is critical to the reliability of the pipe connection.

In some cases, the diameter of the pipe may need to be adjusted to suit different engineering needs or fluid transfer requirements. Pipe reamers can be used to cut the diameter of the end of the pipe to achieve the required size and flow rate.

Pipe reamers can also be used to fabricate specialty piping components such as flanges, pipe couplings and pipe flange gaskets. These components often require precise machining to ensure a perfect fit to the pipe.

A reamer bit is a special type of drill that has a specific design and function and is mainly used for hole machining in metalworking and machine building. Reamer drills have some significant differences from regular drills in terms of working principles and areas of application. The following are the main uses of reamer drills:

1. Making threaded holes: Reamer drills are commonly used to make internally threaded holes. They can create precise threaded holes in metal workpieces for threaded connections or bolting. This is important for mechanical devices, automobile engines and other applications that require threaded connections.

2. Improvement of threaded holes: In some cases, existing threaded holes may need to be trimmed or improved to accommodate specific thread specifications or to repair damaged holes. Reamer bits can be used to clean, adjust and improve existing threaded holes.

3. Fabrication of Insert Screw Holes: Reamer bits may be used to fabricate insert screw holes, which are commonly used to join parts and provide for removable assemblies. Inserted screw holes allow screws to be easily inserted and removed for maintenance and repair.

4. Manufacture of keyways: In mechanical engineering, keyways are used to connect shafts and bushings to enable the transmission of torque or rotational power. Reamer bits can be used to create precise keyways to ensure an accurate fit of the key.

5. Manufacture of pin grooves: Pin grooves are commonly used to install pins or dowels in mechanical devices to connect parts or prevent relative movement of parts. Reamer bits are used to make pin grooves to fit pins of different diameters and lengths.

6. Trimming Orifices: In mechanical engineering, the flatness and accuracy of orifices is important to the assembly and operation of the part. Reamer bits can be used to finish holes to ensure that they are as flat and accurate as required.

7. Manufacturing mounting holes: In mechanical devices, mounting holes are often required to accommodate bearings, threaded sleeves and other parts. Reamer bits are used to make these mounting holes, ensuring the accuracy of the fit to the part.

8. Manufacturing Valve Seats: Valve seats are commonly used in piping systems and valves, and they need to have a flat inner surface to ensure good sealing performance. Reamer drills are used to manufacture valve seats, ensuring the flatness and accuracy of their internal surfaces.

9. Manufacture of machine tool seats: In mechanical engineering, machine tool seats are used to mount and support the various components of the machine tool. Reamer bits can be used to manufacture these seats to ensure the stability and accuracy of the machine.

10. Manufacturing precision holes: Reamer drills can be used to manufacture very precise holes, which often require highly accurate dimensions and surface quality. This is particularly important in aerospace, automotive manufacturing and precision instrumentation.

Hand reaming tools are tools that are manually operated by workers and are typically used in woodworking, metalwork and some fine crafts. These tools are characterized by their simplicity, portability and lack of need for a power source. Common hand reaming tools include:

Hand reamer: This is a hand tool used to make reamed holes. It usually consists of a base with clamps and a handle that the worker rotates to chip away material to form the reamed hole.

Manual Hole Saw: Manual hole saws are used to create holes in wood, plastic and other materials. They have sharp cutting teeth and workers cut holes by manually rotating the hole saw.

Hand Drill: A hand drill is a hand tool used to make holes, usually in metalworking. They can be used to make reamed holes, threaded holes, and other types of holes.

Motorized reaming tools are tools with electric motors that speed up the reaming process and increase productivity. They are commonly used in manufacturing and construction, and in situations where a large number of holes need to be reamed. Common electric reaming tools include:

Electric Reamers: Electric reamers are equipped with an electric motor that allows them to quickly cut reamed holes. They are commonly used in the manufacture of doors, furniture and other items that require hinges.

Electric thread reamers: These tools are used to create threaded holes and are typically used in metal fabrication. They speed up the threading process and increase efficiency.

Power Drills: Power drills are versatile power tools that can be used to make all types of holes, including hinge holes. They are widely used in construction, furniture manufacturing and woodworking.

Reaming machine tools are mechanical devices specifically designed for reaming operations. They are typically used in large-scale manufacturing for high-precision reaming operations. Reaming machines include:

Vertical Reaming Machines: These machines have a vertical working mode, where the workpiece is usually located on the table of the machine and the cutting tool is accessed from above. They are suitable for larger workpieces and high precision reaming operations.

Horizontal reaming machines: Horizontal reaming machines work horizontally, with the workpiece usually clamped to the machine table and the cutting tool accessed from the side. They are suitable for larger workpieces and complex reaming tasks.

Drilling and reaming machines are general-purpose machines which can be used for both drilling and reaming operations. They are usually equipped with automatic feed systems to speed up the production process. These machines are usually used in manufacturing areas and metal working.

CNC reaming machines are reaming machines that use Computer Numerical Control (CNC) technology to control reaming operations through pre-programmed commands. These machines are ideally suited for high-precision reaming needs and can be used to manufacture complex parts and assemblies.

Hand-held reaming tools are small, portable tools typically used for field repair and installation work. They can be used to perform reaming operations on existing workpieces without the need to move the workpiece to the workbench.

Cutters and blades are an important part of reaming tools, which usually have specific geometries and cutting edges for cutting materials to create reamed holes. Different types of cutters and inserts are used for different reaming operations, including threaded reaming, keyway reaming and flathead reaming.

In some cases, ordinary drills and drill chucks can also be used for reaming operations. Drills can be used to make threaded holes and other types of reamed holes by selecting the proper tools and inserts.

Certain applications require specially designed reaming tools to meet specific machining needs. These tools may need to be custom fabricated to accommodate very specific job requirements.

Reaming plays a key role in engineering and manufacturing as an important mechanical joining and motion control technique. It has a wide range of applications, not only for the connection between components, but also for a variety of motions to meet the needs of different fields. The design and manufacture of reamed holes is one of the most important factors that mechanical engineers and manufacturers need to consider during the product development process, and it is essential for creating more efficient, flexible and powerful mechanical systems.

How to Use a Five Axis Machining Center to Process Titanium Alloy Shaped PartsMarch 24, 2023As a five-axis machining center engineer, I will share with you the methods of machining titanium alloy special-shaped parts using a five-axis machining center, as well as the key points of titanium a...view

How to Use a Five Axis Machining Center to Process Titanium Alloy Shaped PartsMarch 24, 2023As a five-axis machining center engineer, I will share with you the methods of machining titanium alloy special-shaped parts using a five-axis machining center, as well as the key points of titanium a...view Snap Fit 101: All You Need to Know About Snap FittingSeptember 19, 2023For a better understanding of snap fitting, we will go through the various types, benefits, and applications of snap fitting and the best tips on designing snap fits.view

Snap Fit 101: All You Need to Know About Snap FittingSeptember 19, 2023For a better understanding of snap fitting, we will go through the various types, benefits, and applications of snap fitting and the best tips on designing snap fits.view How Are Tolerances in Machining Created?October 26, 2023Parts in the processing process, due to various reasons, processing and manufacturing of parts size can not be exactly the same as the size of the parts drawing design, the degree of deviation between the actual geometric parameters and the ideal geometric parameters for the parts processing error.view

How Are Tolerances in Machining Created?October 26, 2023Parts in the processing process, due to various reasons, processing and manufacturing of parts size can not be exactly the same as the size of the parts drawing design, the degree of deviation between the actual geometric parameters and the ideal geometric parameters for the parts processing error.view Exploring the World of High-Speed MachiningNovember 22, 2023In the ever-evolving landscape of manufacturing, the pursuit of efficiency and precision has led us to the realm of High-Speed Machining (HSM).view

Exploring the World of High-Speed MachiningNovember 22, 2023In the ever-evolving landscape of manufacturing, the pursuit of efficiency and precision has led us to the realm of High-Speed Machining (HSM).view 4140 Steel: A Versatile Alloy with Excellent PropertiesDecember 7, 2023Steel is one of the most widely used materials in the world, thanks to its strength, durability, and versatility. However, not all steel grades are the same. Depending on the chemical composition and the heat treatment, different steel grades can have different properties and applications.view

4140 Steel: A Versatile Alloy with Excellent PropertiesDecember 7, 2023Steel is one of the most widely used materials in the world, thanks to its strength, durability, and versatility. However, not all steel grades are the same. Depending on the chemical composition and the heat treatment, different steel grades can have different properties and applications.view Waterjet Cutting: Methods, Applications, and BenefitsJune 21, 2024Waterjet cutting is a special cutting technique that is progressively drawing interest from an increasing number of industries. The technical underpinnings, benefits, and areas of application of waterjet cutting will be thoroughly covered in this article.view

Waterjet Cutting: Methods, Applications, and BenefitsJune 21, 2024Waterjet cutting is a special cutting technique that is progressively drawing interest from an increasing number of industries. The technical underpinnings, benefits, and areas of application of waterjet cutting will be thoroughly covered in this article.view