Medical device components are impacted by rising health costs and technological advancements brought about by the growing aging population. Medical equipment helps to improve the progress of basic medical technology and the impact of people's yearning for a better life. The market demand for medical equipment has been rising, and with the growth of the market, the original business model and customer service have changed. But while keeping up with new technologies and improving costs, some unexpected problems will arise.

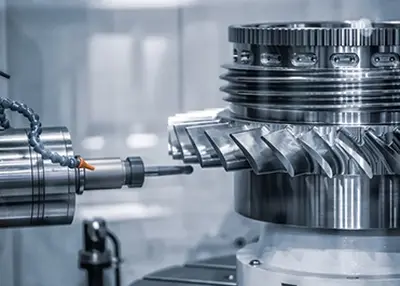

CNC medical parts machining is both a definition and a job. It requires machining medical device parts with ultra-high precision. Manufacturers use CNC machine tools to achieve this goal. They enable manufacturers to machine highly complex medical parts. These are very important for the production of medical devices. First of all, CNC machines can easily handle conventional processes such as turning, boring, drilling, boring, milling and knurling. Manufacturers can then perform special processes such as deep hole drilling, broaching and threading. They do this without multiple setups.

Using medical CNC machining, manufacturers can use CNC to process tiny screws and precision medical parts. Medical parts often require tight tolerances and are often complex. Manufacturers are sometimes under pressure to machine small parts. Therefore, this means that manufacturers must keep up with the processing process of micro-processing. Multi-tool and multi-axis CNC machines enable manufacturers to improve the process and processing time of medical device parts. They shorten cycle times because manufacturers can run all operations on one machine.

Medical devices have highly complex machined parts. Its complex components are particularly important for the stable performance of the device. Designing and processing them requires extraordinary creativity. Fortunately, manufacturers are good at processing high-quality medical precision machining parts. Examples of medical device components are clamps, screws, locking plates, and surgical needles.

Manufacturers use proprietary cost tracking and quality standard systems to optimize costs and maintain quality. This enables manufacturers to produce any number of medical components quickly and cheaply. Manufacturers also offer high-quality CNC cutting tools. They can handle a range of special materials that arise when handling medical parts. Examples of these materials are nickel, titanium, cobalt chrome and stainless steel.

The complexity and delicacy of CNC medical parts determine the requirements for CNC coding and engineering. This ensures that the customer's demand for workpiece accuracy is met. A high-end CNC machine tool machines the bushings. This ensures that the cutting tool is never too far from the workpiece. Because it reduces errors due to distance deflection. This is especially important when dealing with slender medical components. In addition, it can help manufacturers deal with small-scale and delicate parts. Its speed and efficiency allow for quick and flexible responses. This still ensures repeatability regardless of volume. Medical CNC machining as a prototyping method can speed up the entire process. Manufacturers further combine it with precision grinding, allowing manufacturers to respond to customer needs.

Unveiling the World of Helical Machined Springs: A Comprehensive ExplorationNovember 15, 2023Embarking on a journey through the intricate world of helical machined springs is more than just an exploration of engineering marvels – it's a pathway to unlocking innovation, efficiency, and reliability in diverse industries. In this article, I'll guide you through the essential aspects of helical machined springs, from their fundamental workings to practical applications and market trends.view

Unveiling the World of Helical Machined Springs: A Comprehensive ExplorationNovember 15, 2023Embarking on a journey through the intricate world of helical machined springs is more than just an exploration of engineering marvels – it's a pathway to unlocking innovation, efficiency, and reliability in diverse industries. In this article, I'll guide you through the essential aspects of helical machined springs, from their fundamental workings to practical applications and market trends.view What is Tensile Strength for CNC Machining?October 25, 2023Tensile strength is a key characteristic that engineers and materials specialists must consider when designing and selecting materials for their applications. It is the maximum stress that a material can withstand before it breaks or deforms under tension.view

What is Tensile Strength for CNC Machining?October 25, 2023Tensile strength is a key characteristic that engineers and materials specialists must consider when designing and selecting materials for their applications. It is the maximum stress that a material can withstand before it breaks or deforms under tension.view Top 12 CNC Machining Manufacturers in the USAJune 8, 2024Looking for reliable CNC machining parts manufacturers in the USA? Check out our list of the top 12 companies, each with its own unique advantages and processing capacities. Find the perfect partner for your business today!view

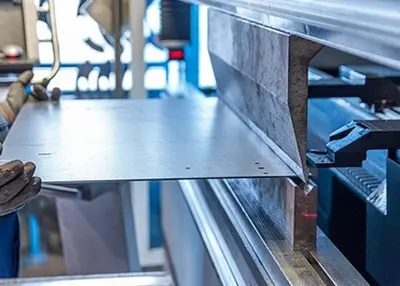

Top 12 CNC Machining Manufacturers in the USAJune 8, 2024Looking for reliable CNC machining parts manufacturers in the USA? Check out our list of the top 12 companies, each with its own unique advantages and processing capacities. Find the perfect partner for your business today!view Sheet Metal Thickness Conversion Chart: Galvanized Steel, Stainless Steel, AluminumDecember 5, 2023In sheet metal work, the term "gauge" is frequently employed to specify thickness. Gauges are the units used to indicate the thickness of a metal sheet.view

Sheet Metal Thickness Conversion Chart: Galvanized Steel, Stainless Steel, AluminumDecember 5, 2023In sheet metal work, the term "gauge" is frequently employed to specify thickness. Gauges are the units used to indicate the thickness of a metal sheet.view Metal Milling Techniques and ApplicationsNovember 3, 2023Are you fascinated by the art of shaping metal into precision components or intricate designs? In this comprehensive guide, I'll walk you through the world of metal milling, from the fundamental concepts to advanced applications.view

Metal Milling Techniques and ApplicationsNovember 3, 2023Are you fascinated by the art of shaping metal into precision components or intricate designs? In this comprehensive guide, I'll walk you through the world of metal milling, from the fundamental concepts to advanced applications.view Titanium vs. Aluminum: High Performance Metals for Machining and 3D PrintingOctober 11, 2023When you think of an outstanding combination of material properties for parts, light weight and strength come to mind. Of course, the same is true for aluminum and titanium. Both materials meet other important criteria, such as excellent corrosion resistance and heat tolerance.view

Titanium vs. Aluminum: High Performance Metals for Machining and 3D PrintingOctober 11, 2023When you think of an outstanding combination of material properties for parts, light weight and strength come to mind. Of course, the same is true for aluminum and titanium. Both materials meet other important criteria, such as excellent corrosion resistance and heat tolerance.view

EN

EN

ru

ru