Rivets hold a unique position in the history of engineering and construction. These seemingly small fasteners have played a critical role in joining materials together. Based on their properties and design requirements, different types of rivets for different applications are available. For your reference, this article covers different types of rivets that you may need. Let’s get started!

A rivet is a mechanical fastener or connector that has a head and tail on opposite sides. It features a smooth cylindrical body, a head, and a tail that resembles a metallic pin. Rivets are often constructed of aluminum, steel, or other materials. These fasteners are not tightened in the same way as bolts and nuts are.

There are several types of rivets available. They are simply classified into the following categories.

Solid rivets are one of the most common and dependable types of fastening. Solid rivets are made comprised of a simple shaft and head bent with a hammer or rivet gun. A compression or crimping tool can also be used to deform this type of rivet. Because the depth of the tool's frame restricts its use, it is frequently used on rivets near the edge of the material being fastened. Installing strong rivets with a rivet compression tool is usually the most secure approach and does not necessitate the use of two people.

The mandrel snaps off when the blind end of the rivets expands. Unlike solid rivets, blind rivets can be installed from one side of the part. Blind rivets are useful when it is difficult to view the back end of a joint. It is as simple and quick to apply as any other rivet. The following are some types of common blind rivets:

Pull-Mandrel Rivets

Pull-mandrel rivets, also known as pull-through rivets or blind breakstem rivets, are a type of blind rivet that features a mandrel or stem connected to the rivet body. It has a tight radial set which will increase structural rigidity.

Threaded Rivets

Threaded rivets are often referred to as blind rivet nuts or threaded inserts. This variation of standard blind rivets can be anchored from one side of the installed part. There are standard and heavy-duty threaded rivets. Heavy-duty rivets, on the other hand, heavy-duty sidewalls and heads. As a result, they are useful for high-performance and demanding applications.

Drive-Pin Rivets

Drive-Pin rivets are blind rivets that have short mandrels extending from their heads. Once a drive-pin rivet is inserted into a hole, its mandrel can be worked with a hammer or other material. This flares out the end of the rivet that is into the hole. Because they do not require drilling, drive-pin rivets are more suitable for architectural and other aesthetically pleasing applications.

Tubular rivets are made of a hollow tube with a head on one end and a threaded shaft on the other end. The shaft is inserted into pre-drilled holes in the materials to be joined, and a tool is used to deform the end of the shaft, creating a secure and permanent connection. Tubular rivets are commonly used in applications where a strong and durable connection is required, such as in the automotive, aerospace, and construction industries.

Flush rivets are the type of fastener that is widely used in aircraft construction and other industries. When installed, it is designed to create a smooth and level surface made of aluminum or stainless steel. These rivets are required for attaching sheet metal panels in the fuselage or wings of the aircraft.

Split rivets, also known as bifurcated rivets, are a type of self-piercing rivet used to link softer materials like textiles, leather, plastic, or wood. These rivets are pre-split down the length of their shaft, forming two "legs"; when installed, the legs of a split rivet fold back to hold the attached materials together.

This category of rivets does not call that pre-drilled holes are not required, allowing the joint to be made quickly in one operation. Self-piercing riveting is a high-speed mechanical fastening process used to attach sheets of steel and aluminum alloys. It is a single-step method that uses a semi-tubular rivet to clinch the sheets in a mechanical junction.

Rivets are extensively used in the aerospace industry for joining various components of an aircraft. For aircraft, the main objective is to have a solid alignment and the strongest combination of parts linked together, and riveting is essential to achieve this. Rivets are used to attach aluminum alloys together since they are difficult to solder. Riveting also assures neatness and robustness, creating room for lighter weight in aircraft.

Rivets are commonly used in jewelry-making to connect different pieces of metal, gemstones, or other materials. They add strength and stability to the jewelry piece while also providing an attractive decorative element. Rivets can be found in bracelets, earrings, necklaces, and other types of jewelry.

Rivets are often used to join metal parts or components together, especially in applications where welding or other methods are not suitable or preferred. They can be used in industries such as construction, automotive, and the manufacturing of furniture and appliances. Riveted joints have excellent strength and can withstand heavy loads and vibrations.

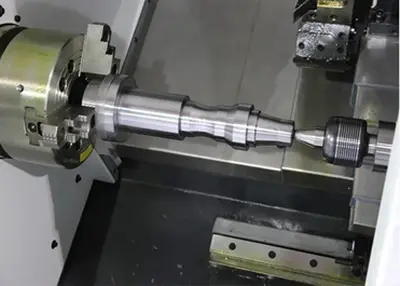

Riveting programs that can be parameterized at any time have been a distinctive feature of metal CNC machine control. The present CNC control, which includes a touchscreen display, process data acquisition, and numerous interfaces, ensures simple machine operation. Here is what you can get from Richconn on metal CNC services:

Offer a machine table to securely hold and position the workpiece during the manufacturing process of a rivet;

Deliver the best custom precision CNC machining services for prototyping and production machining for rivets;

With advanced technology and powerful machines, it enables multi-dimensional rivet-machining operations with fast lead times;

Follow a modular configuration to flexible customization and can be easily adapted or expanded according to the specific machining requirements;

Give you high-quality rivets at a low cost.

Once you send us the design file, our team will deliver an instant quote to you quickly.

Rivets are a superior alternative to screws, bolts, and nuts. They outperform all other connectors in terms of efficiency and dependability. Richconn offers critical OEM CNC machining for metal rivets. We also provide cost-effective CNC machining services for prototyping and production. No matter what rivet type you need and no matter when you need the best rivets for CNC machining, contact Richconn.

Can Titanium Be Machined: Comprehensive analysis of CNC machining of titanium materialsNovember 10, 2023Greetings, machining enthusiasts! Have you ever wondered if titanium, that resilient and lightweight metal, can truly be harnessed through CNC machining? I'm here to not only answer your burning question but to delve into the intricacies, challenges, and best practices associated with machining titanium. As Richconn, your go-to precision machine shop, let's unlock the full potential of this extraordinary material together.view

Can Titanium Be Machined: Comprehensive analysis of CNC machining of titanium materialsNovember 10, 2023Greetings, machining enthusiasts! Have you ever wondered if titanium, that resilient and lightweight metal, can truly be harnessed through CNC machining? I'm here to not only answer your burning question but to delve into the intricacies, challenges, and best practices associated with machining titanium. As Richconn, your go-to precision machine shop, let's unlock the full potential of this extraordinary material together.view Everything About Roller - Materials, Processing, ProductsJune 15, 2023In this era of rapid change, mechanical equipment is developing rapidly, the degree of automation and intelligence in production is continuously improving, and the performance indicators of mechanical...view

Everything About Roller - Materials, Processing, ProductsJune 15, 2023In this era of rapid change, mechanical equipment is developing rapidly, the degree of automation and intelligence in production is continuously improving, and the performance indicators of mechanical...view Titanium vs Stainless Steel: Choosing the Right Material for Your MachiningNovember 24, 2023Understand the differences between titanium and stainless steel and choose the best material for CNC machining.view

Titanium vs Stainless Steel: Choosing the Right Material for Your MachiningNovember 24, 2023Understand the differences between titanium and stainless steel and choose the best material for CNC machining.view Common Cheap CNC Material - An Overview of PlasticsJune 17, 2024Cheap CNC Material——ABSABS is one of the most common cheap CNC material, with good mechanical properties, excellent impact strength, high heat resistance, and good machinability.ABS has a low densit...view

Common Cheap CNC Material - An Overview of PlasticsJune 17, 2024Cheap CNC Material——ABSABS is one of the most common cheap CNC material, with good mechanical properties, excellent impact strength, high heat resistance, and good machinability.ABS has a low densit...view 5 Important Facts About 5 Axis Machining | Basics Information, Benefits, Limitations, Applications & TipsFebruary 20, 20245 axis CNC machining technology is important in manufacturing. Learn more about its basics, pros &cons, applications, and tips to enhance your project performance.view

5 Important Facts About 5 Axis Machining | Basics Information, Benefits, Limitations, Applications & TipsFebruary 20, 20245 axis CNC machining technology is important in manufacturing. Learn more about its basics, pros &cons, applications, and tips to enhance your project performance.view Six Key Points of CNC MachiningApril 4, 2023Many manufacturers know that in the process of CNC machining center, it is crucial to avoid collisions when programming and operating the machine tool. After all, CNC machining centers are not cheap, ...view

Six Key Points of CNC MachiningApril 4, 2023Many manufacturers know that in the process of CNC machining center, it is crucial to avoid collisions when programming and operating the machine tool. After all, CNC machining centers are not cheap, ...view

EN

EN

ru

ru