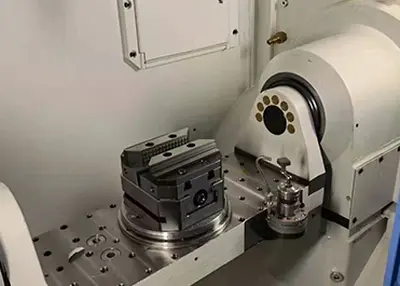

The CNC turning process is the sum of the methods and technical means used when CNC lathes are used to process parts. Its main contents include the following aspects:

(1) Select and determine the CNC turning content of the parts;

(2) Analysis of CNC turning processing technology for part drawings;

(3) Selection and adjustment design of tools and fixtures;

(4) Design of working procedures and steps;

(5) Calculation and optimization of machining trajectory;

(6) Compilation, verification and modification of CNC turning programs;

(7) Trial CNC machining processing of the first piece and handling of on-site problems;

(8) Compile technical documents of CNC machining process; in short, there are many CNC machining process contents, some of which are similar to ordinary machine tool processing.

Process analysis is the pre-process preparation for CNC turning. Whether the process is reasonable or not has an important impact on the compilation of the program, the machining efficiency of the CNC machine tools materials and the machining accuracy of the parts. In order to compile a reasonable and practical machining program, programmers are required not only to understand the working principle, performance characteristics and structure of CNC lathes. Master the programming language and programming format, and also master the workpiece processing technology, determine the reasonable cutting amount, and correctly select the tool and workpiece clamping method. Therefore, we should follow the general process principles and combine the characteristics of CNC lathes to conduct a careful and detailed analysis of the CNC turning process. Its main contents include: analyzing the processing requirements and rationality of the parts according to the drawings; determining the clamping method of the workpiece on the CNC lathe; the processing sequence of each surface, the feed route of the tool, and the selection of the tool, fixture and cutting amount, etc.

How do you charge for sleeve parts machining?October 31, 2023Sleeve parts machining charges will be involved in the structural design, machining process, hole size, material selection and other requirements, any one of the different processing needs will lead to a great difference in price, so the need for a relatively accurate quote must provide a complete design drawings, engineers will be based on the design of the drawings labeled materials, dimensions, process, accuracy, structure, table at the detailed parameters such as calculating the accurate quote.view

How do you charge for sleeve parts machining?October 31, 2023Sleeve parts machining charges will be involved in the structural design, machining process, hole size, material selection and other requirements, any one of the different processing needs will lead to a great difference in price, so the need for a relatively accurate quote must provide a complete design drawings, engineers will be based on the design of the drawings labeled materials, dimensions, process, accuracy, structure, table at the detailed parameters such as calculating the accurate quote.view What Is A Coordinate Measuring Machine Used For?July 16, 2024A coordinate measuring machine is often used to qualify rapid prototypes and production parts that have complex geometries with tight tolerances. Learn more about it to ensure every part you make meets and exceeds your expectations.view

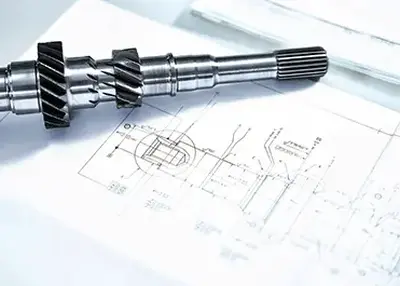

What Is A Coordinate Measuring Machine Used For?July 16, 2024A coordinate measuring machine is often used to qualify rapid prototypes and production parts that have complex geometries with tight tolerances. Learn more about it to ensure every part you make meets and exceeds your expectations.view Unlocking the Secrets of Spline Machining: A Comprehensive GuideNovember 15, 2023In the intricate world of manufacturing, the precision required for creating components like splines demands a deep understanding of machining processes. In this comprehensive guide, we embark on a detailed exploration of the art and science behind spline machining, unraveling its complexities and unveiling the techniques that shape these vital engineering elements.view

Unlocking the Secrets of Spline Machining: A Comprehensive GuideNovember 15, 2023In the intricate world of manufacturing, the precision required for creating components like splines demands a deep understanding of machining processes. In this comprehensive guide, we embark on a detailed exploration of the art and science behind spline machining, unraveling its complexities and unveiling the techniques that shape these vital engineering elements.view The Crucial World of Mechanical Testing for Materials: Insights and ImportanceJuly 22, 2024Mechanical testing is the key to understanding materials' reliability and performance. Let’s find out its vital role in industries, types of tests, features, etc. in this article!view

The Crucial World of Mechanical Testing for Materials: Insights and ImportanceJuly 22, 2024Mechanical testing is the key to understanding materials' reliability and performance. Let’s find out its vital role in industries, types of tests, features, etc. in this article!view About PVD Surface Treatment Technology and Its ApplicationSeptember 16, 2022With the rapid development of the automobile industry and the improvement of the technological level, especially the wide application of high-strength plates in automobile sheet metal, the cold work d...view

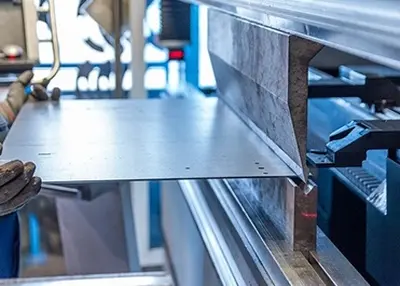

About PVD Surface Treatment Technology and Its ApplicationSeptember 16, 2022With the rapid development of the automobile industry and the improvement of the technological level, especially the wide application of high-strength plates in automobile sheet metal, the cold work d...view 5 Bending and Forming Methods for Sheet MetalDecember 4, 2023Sheet metal refers to a process used to manufacture a variety of metal products, which involves processing sheet metal into the desired shape and size by cutting, stamping, bending, and welding.view

5 Bending and Forming Methods for Sheet MetalDecember 4, 2023Sheet metal refers to a process used to manufacture a variety of metal products, which involves processing sheet metal into the desired shape and size by cutting, stamping, bending, and welding.view

EN

EN

ru

ru