Choosing the appropriate CNC Manufacturing shop is one of the many important considerations that must be made before starting a manufacturing project. This choice could have a big impact on how your project develops. The skills, quality assurance, technological know-how, and delivery effectiveness of the selected shop can either strengthen or weaken your project.

A specialized facility where CNC machines are used for part manufacturing or modification is called a CNC machining shop. These shops are equipped with CNC turning and milling equipment provided by machine manufacturers as well as more sophisticated multi-axis CNC machine techniques.

Custom machining is a service offered by CNC machine shops wherein parts are manufactured in accordance with customers' precise dimensional specifications. To guarantee that your CNC machining and manufacturing needs are satisfied to the greatest standards, a reputable CNC machine shop operates on the tenets of quality, precision, and timely delivery.

It is crucial to consider a number of things when choosing a CNC manufacturing shop to make sure you are making the best choice. Here are a few important points:

l Experience

Machinists with more experience have a higher chance of managing challenging machining tasks effectively. Seek out shops where the machinists have practical experience with a range of materials and machining techniques.

l Delivery Time

A shop that can produce high-quality duplicate parts on schedule is necessary for high-volume production. It is crucial to assess how well they handle short batches and large output, as well as how long their lead times are.

l Machining Proficiency

Verify whether the CNC machining company has the tools and technologies required to complete the needs of your project. This comprises coordinate measurement equipment for quality control in certain cases, as well as CNC lathes provided by CNC lathe manufacturers, CNC milling machines, and grinding machines.

l Certifications

An indication of a store's dedication to providing high-quality services is its ISO 9001 certification from the International Organization for Standardization (ISO).

l Quality Control

To guarantee the manufacturing of high-quality parts, a reputable CNC machine shop adheres to strict quality control methods. Utilizing tools such as coordinate measuring machines, pin gauges, and contemporary software, they ensure accuracy and conformity to the initial dimensions specifications. You must be provided with the quality control records that are available in addition to performance information so that you can truly understand the business that is being evaluated for precision or custom CNC machining.

The extensive use of CNC machining technology in China has drawn interest from international businesses. The following are the justifications for selecting Chinese CNC manufacturing services:

l Technology and Quality

China's CNC manufacturing services often use state-of-the-art machinery and cutting-edge technology to produce high-quality goods and highly precise machining.

l Price Competitiveness

High-quality manufacturing services can be obtained in China at a reasonable cost, and CNC manufacturing services are typically competitively priced.

l Flexibility and Responsiveness

CNC manufacturing services in China are typically very responsive and adaptable, allowing for speedy customization and delivery of services in accordance with client requirements.

l Expert Teams and Service Support

In China, CNC manufacturing services are often rendered by seasoned professional teams that are able to offer prompt, high-quality service support.

l After-sales Support and Maintenance Services

Most CNC manufacturing China shops typically offer excellent after-sales support, which includes equipment maintenance and repair, ensuring that the client's equipment is always in the best possible shape.

The success of your company depends on selecting trustworthy CNC manufacturing companies in the cutthroat industry of today. Richconn is a reputable CNC machining parts manufacturer that has gained the trust of numerous organizations as their go-to partner because of its high level of technical proficiency, excellent customer service, and effective machining capabilities.

l Trustworthiness

Purchasing a computer numerical control (CNC) machine tool is an uncommon occurrence. The entire process, from concept to delivery, takes place. Businesses invest a lot of effort and money before placing an order for a custom CNC machine tool. As a result, it's critical to select machining equipment that is more dependable and error-free. Selecting the best equipment for your business requires thorough research into the advantages of each manufacturer.

Looking for services of CNC manufacturing near me or CNC milling machine manufacturers? You have come to the right place! Richconn is known for being a top supplier of CNC machining, and in addition to offering dependable, high-quality machines at competitive prices, we also put a strong emphasis on establishing long-term relationships with our clients. This will help you save money and time in the long run by preventing needless repairs.

l Choice and Accessibility of Materials

Your company has to locate a machine shop that can operate with a variety of materials if it offers various CNC machining services. Various materials are used to create CNC machined parts, but the most popular ones are copper, stainless steel, and aluminum.

Richconn gives customers more than 50 materials to select from, so be sure to ask your machine shop if these materials are accessible before making a high-volume manufacturing order. We provide CNC machining services for various metals, polymers, and wood materials.

l Procedures for Surface Treatment

Accuracy surface finishes and precise parameters are necessary for CNC machining. Without performing a surface preparation procedure, no machining operation is finished. These procedures are designed to improve the surface finish of objects that have been CNC machined and turned.

Richconn provides a large range of surface finish options to its customers. Surface finishes include plating, sandblasting, brushing, and anodizing are all within our team's capabilities. Additionally, your company may be able to save money by partnering with a fabrication firm that provides an all-inclusive service.

You may find it difficult to choose the best CNC machining firm because there are so many things to take into account. Numerous factors need to be considered, including the availability of materials, surface treatment, production capacity, and other factors. The best way to decide that is to study the market. Take a personal look at each CNC manufacturer if you have the time. It will provide you with all the details you need.

But first, take a look at Richconn before looking for the best CNC machining firm. For all the information you require, feel free to visit our facilities or get in touch with our friendly staff.

Machined Castings - Your Comprehensive GuideNovember 7, 2023Are you looking to delve into the fascinating world of machined castings? Are you curious about how these essential components are made, their diverse applications, and the key factors to consider when choosing a supplier?view

Machined Castings - Your Comprehensive GuideNovember 7, 2023Are you looking to delve into the fascinating world of machined castings? Are you curious about how these essential components are made, their diverse applications, and the key factors to consider when choosing a supplier?view CNC Control Systems: Unraveling the Core of Computer Numerical ControlNovember 3, 2023Are you ready to delve into the heart of modern manufacturing technology? Welcome to the world of CNC Control Systems, where precision and automation meet to revolutionize industries.view

CNC Control Systems: Unraveling the Core of Computer Numerical ControlNovember 3, 2023Are you ready to delve into the heart of modern manufacturing technology? Welcome to the world of CNC Control Systems, where precision and automation meet to revolutionize industries.view What is a shaft in manufacturing? Detailed Process and TypesMay 4, 2024Explore the detailed process of shaft machining, its types, and surface finish choice. Discover challenges where shaft machining could be avoided.view

What is a shaft in manufacturing? Detailed Process and TypesMay 4, 2024Explore the detailed process of shaft machining, its types, and surface finish choice. Discover challenges where shaft machining could be avoided.view What Are The Characteristics and Features of CNC Machining?June 21, 2022Process concentration, automation, high flexibility, and strong capabilities are the characteristics of CNC machining. The process rules of CNC machining and traditional machine tool machining are gen...view

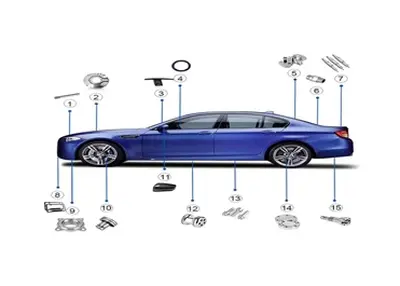

What Are The Characteristics and Features of CNC Machining?June 21, 2022Process concentration, automation, high flexibility, and strong capabilities are the characteristics of CNC machining. The process rules of CNC machining and traditional machine tool machining are gen...view The Precision of CNC Automotive Parts in Gear SystemsJanuary 5, 2024In the world of automotive manufacturing, precision and reliability are crucial for the smooth operation of gear systems. As technology advances, the demand for precision components in the automotive ...view

The Precision of CNC Automotive Parts in Gear SystemsJanuary 5, 2024In the world of automotive manufacturing, precision and reliability are crucial for the smooth operation of gear systems. As technology advances, the demand for precision components in the automotive ...view Drill and Tap Specification ChartNovember 17, 2023In CNC machining, the usual process is to use a drill bit to drill a hole in the workpiece and then use a tap of the appropriate size to cut the desired threads in the hole. This ensures that the threads match the design requirements and can ensure that the threads fit correctly with other components.view

Drill and Tap Specification ChartNovember 17, 2023In CNC machining, the usual process is to use a drill bit to drill a hole in the workpiece and then use a tap of the appropriate size to cut the desired threads in the hole. This ensures that the threads match the design requirements and can ensure that the threads fit correctly with other components.view

EN

EN

ru

ru