Welcome to the fascinating world of nylon, a material that has revolutionized industries, from fashion to manufacturing. In this article, I will take you on a journey through the intricate web of nylon, unraveling its diverse uses, delving into its chemical composition, exploring its unique fiber properties, comparing it with polyester, uncovering its plastic applications, and finally, discovering its crucial role in 3D printing. So, let's dive right in!

In this section, we will delve deeper into the various applications of nylon, and I'll provide some data for a table that highlights its uses in different industries.

Nylon's remarkable strength and versatility have made it a cornerstone of the textile industry. From silky stockings to rugged outdoor wear, nylon fibers have revolutionized our wardrobes. Nylon garments not only withstand the test of time but also offer comfort and style.

| Application | Description |

|---|---|

| Clothing | Undergarments, hosiery, sportswear, and outerwear made from nylon for durability and comfort. |

| Home Furnishings | Nylon-based fabrics for upholstery, curtains, and bedding due to their durability and easy maintenance. |

| Outdoor Gear | Use in hiking, camping, and sports clothing for moisture-wicking and abrasion resistance. |

In the industrial world, nylon proves its mettle. It finds its way into manufacturing tough products like ropes, hoses, and conveyor belts. Nylon's ability to withstand extreme conditions, including high pressure and abrasion, makes it an indispensable material in industries worldwide.

| Application | Description |

|---|---|

| Ropes and Cables | Nylon ropes are favored for their strength and flexibility, ideal for climbing, sailing, and towing. |

| Hoses | Nylon hoses are used in automotive, aviation, and industrial settings due to their resistance to chemicals and abrasion. |

| Conveyor Belts | Nylon conveyor belts are essential in manufacturing, food processing, and logistics due to their durability and low friction. |

The automotive industry embraces nylon for its lightweight yet robust qualities. From air intake manifolds to engine covers, nylon components reduce vehicle weight without compromising strength. This contributes to better fuel efficiency and performance.

| Component | Description |

|---|---|

| Air Intake Manifolds | Nylon's heat resistance and light weight make it an ideal choice for these critical engine components. |

| Engine Covers | Lightweight nylon engine covers reduce overall vehicle weight, enhancing fuel efficiency. |

| Fasteners and Clips | Nylon fasteners and clips provide durability and reduced weight in vehicle assembly. |

Pro Tip: When considering a new car, inquire about the use of nylon components for improved efficiency.

In the realm of sports, nylon enhances performance and longevity. Equipment like tennis strings, fishing lines, and even climbing gear often rely on nylon's resilience to ensure that athletes and enthusiasts can push their limits.

| Equipment | Description |

|---|---|

| Tennis Strings | Nylon strings offer durability and control, favored by professional tennis players. |

| Fishing Lines | Nylon fishing lines provide strength, flexibility, and low visibility in the water. |

| Climbing Gear | Nylon ropes and harnesses are essential for safety and durability in climbing and mountaineering. |

Nylon's secret lies in its chemical structure, which involves the polymerization of specific monomers. This results in a robust material with unique properties. Understanding nylon's chemistry sheds light on its wide range of applications.

| Component | Role in Nylon Production |

|---|---|

| Monomers | Specific monomers, such as adipic acid and hexamethylenediamine, are polymerized to create nylon. |

| Polymerization Process | Monomers undergo a chemical reaction to form long chains of nylon molecules, resulting in various types of nylon. |

Nylon's invention by DuPont marked a pivotal moment in the history of materials science. Since then, it has continued to evolve, adapting to new challenges and environmental concerns. Discover how nylon went from being a marvel of the 20th century to an indispensable part of our lives.

| Year | Milestone |

|---|---|

| 1935 | DuPont introduces Nylon 66, the first commercially successful nylon. |

| 1940s-1950s | Nylon becomes widely used in World War II for parachutes and military gear. |

| 1959 | DuPont introduces Nylon 6, expanding nylon's versatility. |

| 21st Century | Ongoing research into sustainable and bio-based nylon materials. |

While nylon offers numerous benefits, its production has raised environmental concerns. However, innovative solutions are emerging to create more sustainable nylon materials. Learn about the ongoing efforts to reduce the ecological footprint of this versatile material.

| Concern | Efforts and Solutions |

|---|---|

| Resource Consumption | Research into bio-based and recycled nylon materials to reduce reliance on fossil fuels. |

| Waste Management | Recycling initiatives and exploring circular economy models for nylon products. |

| Pollution | Developing eco-friendly production processes and reducing emissions. |

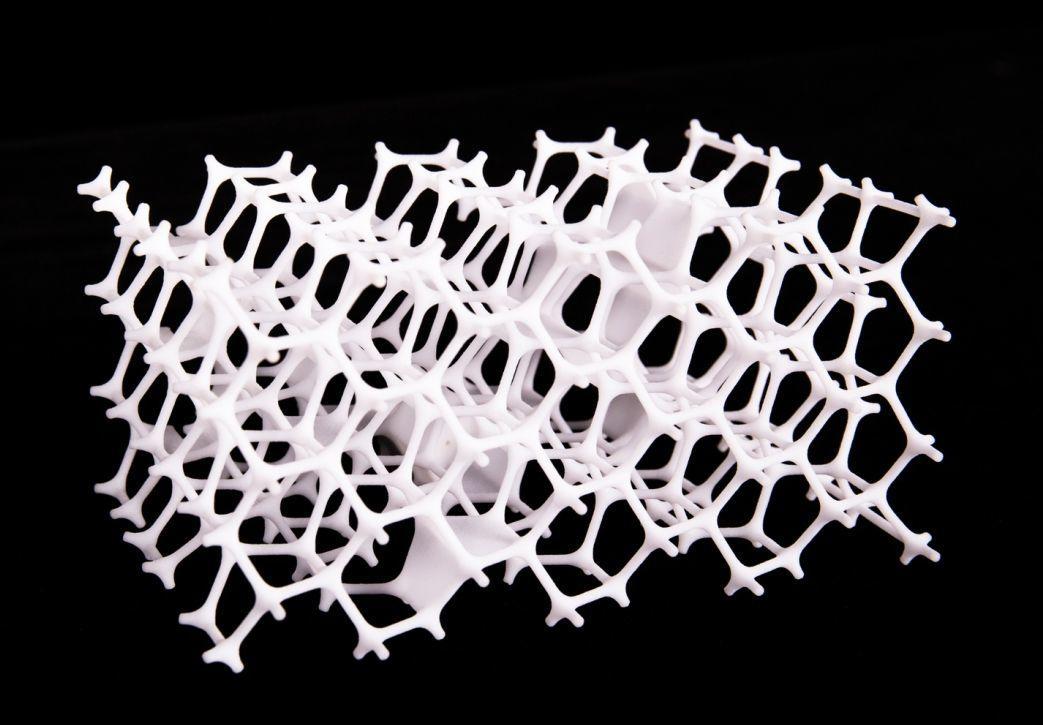

Figure Future 7100 nylon (left SLS) vs. 7500 nylon (right MJF)

Nylon fibers possess extraordinary properties, including strength, elasticity, and moisture resistance. These characteristics make them ideal for a wide range of applications, from clothing to industrial uses.

| Property | Description |

|---|---|

| Strength | Nylon fibers are exceptionally strong, often exceeding the strength of natural fibers like cotton or silk. |

| Elasticity | Nylon fibers have excellent elasticity, allowing them to stretch without permanent deformation. |

| Moisture Resistance | Nylon repels moisture and dries quickly, making it suitable for outdoor and athletic wear. |

The process of turning nylon into fibers is meticulous. Understanding this manufacturing process helps us appreciate the craftsmanship behind our nylon garments, ensuring that they provide both comfort and style.

| Stage | Description |

|---|---|

| Polymerization | Nylon polymer is produced through a reaction of monomers, creating long chains. |

| Melting and Extrusion | The polymer is melted and extruded through tiny holes to create filaments. |

| Spinning | Filaments are spun into fibers, which are then stretched to align molecules and increase strength. |

| Texturing | Texturing processes give nylon fibers their softness and bulk, enhancing comfort. |

| Fabric Formation | Nylon fibers are woven or knit into fabrics, ready for use in various applications. |

Contrasting the chemical makeup of nylon and polyester reveals the subtle differences that impact their performance. This knowledge empowers consumers and professionals to make informed choices.

| Characteristic | Nylon | Polyester |

|---|---|---|

| Polymer Composition | Derived from polyamide monomers. | Derived from ester monomers. |

| Moisture Absorption | Absorbs moisture and retains some water. | Resistant to moisture absorption. |

| Heat Resistance | Melts at a lower temperature than polyester. | Higher melting point, more heat-resistant. |

Nylon and polyester excel in different scenarios. Understanding their relative strengths and weaknesses can guide your material choices, whether you're purchasing clothing, industrial equipment, or everyday items.

| Aspect | Nylon | Polyester |

|---|---|---|

| Tensile Strength | Exceptionally strong and durable. | Strong, but generally less than nylon. |

| Abrasion Resistance | Highly resistant to abrasion and wear. | Also resistant, but may wear faster than nylon. |

| Stretchability | Offers excellent elasticity and recovery. | Less stretch, less likely to sag over time. |

Nylon's versatility extends to the world of plastics, where it serves as a key ingredient in creating durable, heat-resistant, and low-friction plastic products. Whether you're in engineering or simply seeking reliable consumer goods, nylon plays a vital role.

Nylon's unique properties make it a standout choice in the realm of plastics. It possesses a combination of strength, heat resistance, and low friction, which sets it apart from many other plastics.

Delve deeper into the advantages of using nylon in plastic applications. Its properties open the door to engineering excellence, making it an indispensable material in various industries.

| Property | Advantages of Nylon in Plastics |

|---|---|

| Strength | Nylon's high strength-to-weight ratio is ideal for structural components. |

| Heat Resistance | It can withstand high temperatures without deformation. |

| Low Friction | Nylon's low coefficient of friction reduces wear and tear in moving parts. |

| Durability | Resistant to chemicals, abrasion, and impact, ensuring longevity. |

| Electrical Insulation | Nylon is an excellent electrical insulator, vital in electrical applications. |

Nylon has emerged as a key player in the world of 3D printing services, shaping the future of additive manufacturing. Its unique properties, including strength and flexibility, make it an excellent choice for creating intricate and functional prototypes.

In the realm of 3D printing, nylon has gained recognition for its versatility. It allows for the creation of intricate and functional objects that meet the demands of various industries.

| Advantage | Description |

|---|---|

| Strength | Nylon's strength and flexibility make it suitable for printing durable and functional prototypes. |

| Precision | Nylon allows for high-resolution printing, producing intricate details. |

| Chemical Resistance | Resistant to chemicals, nylon prints can withstand exposure to various substances. |

| Low Friction | Nylon's low friction properties are ideal for producing moving parts. |

Nylon's role in 3D printing goes beyond prototypes. It finds applications in aerospace, medical fields, and more. Let's explore the specific areas where nylon's precision and innovation are driving progress.

| Application | Description |

|---|---|

| Aerospace | Nylon's strength and light weight make it ideal for producing aircraft components. |

| Medical Devices | 3D-printed nylon is used to create custom prosthetics and surgical instruments. |

| Engineering Prototypes | Engineers use nylon 3D printing to create functional prototypes for testing and development. |

In our journey through the multifaceted world of nylon, we've uncovered a material that has woven its way into the fabric of our lives, quite literally. From the fashion industry's durable garments to the industrial sector's robust applications, nylon has proven its mettle time and again.

We began by exploring the diverse uses of nylon, from clothing that fuses style with durability to industrial applications where strength is paramount. Then, we ventured into the realm of chemistry, tracing nylon's composition back to its polymer roots and understanding its historical evolution and ongoing sustainability efforts.

As we unraveled the secrets of nylon fibers, we discovered their exceptional strength, elasticity, and moisture resistance—properties that have elevated textiles to new heights. We also delved into the differences between nylon and polyester, enabling you to make informed choices in a world filled with synthetic options.

Our exploration continued into the world of plastics, where nylon's strength, heat resistance, and low friction properties make it a standout choice. From everyday consumer goods to critical engineering components, nylon's presence is ubiquitous.

Finally, we embarked on a journey into the future, where nylon takes center stage in the revolutionary realm of 3D printing. Its precision, strength, and versatility are pushing the boundaries of innovation in industries as diverse as aerospace and healthcare.

In closing, whether you're choosing clothing, industrial equipment, or embarking on a creative project, remember that nylon is more than just a material—it's a symbol of strength, innovation, and endless possibilities. As you navigate the world of nylon, armed with knowledge, you can make choices that not only enhance your life but also contribute to a more sustainable and efficient future.

So, embrace the power of nylon, and let it weave its way into your world, enhancing your experiences and shaping the landscapes of tomorrow. The journey doesn't end here; it's just the beginning of a fascinating exploration into the limitless potential of this remarkable material.

At Richconn, we are your premier CNC machining service company, and we're proud to introduce our cutting-edge nylon 3D printing services. Experience precision, innovation, and excellence as we bring your ideas to life in high-quality nylon. Discover limitless possibilities with Richconn's nylon 3D printing solutions.

What Workpieces Are Mainly Used for 4-axis CNC Machining?August 10, 2022The continuous improvement of the automation degree of 4-axis CNC machining and the development of mechanized systems make the process scope continue to expand. 4-axis CNC machining maximizes the cont...view

What Workpieces Are Mainly Used for 4-axis CNC Machining?August 10, 2022The continuous improvement of the automation degree of 4-axis CNC machining and the development of mechanized systems make the process scope continue to expand. 4-axis CNC machining maximizes the cont...view Demystifying CNC Lathe Machining – Unveiling the Precision PowerhouseNovember 3, 2023In the heart of precision manufacturing, CNC (Computer Numerical Control) lathe machining stands as a true marvel. It's a technology that has transformed the way we create parts and components across various industries.view

Demystifying CNC Lathe Machining – Unveiling the Precision PowerhouseNovember 3, 2023In the heart of precision manufacturing, CNC (Computer Numerical Control) lathe machining stands as a true marvel. It's a technology that has transformed the way we create parts and components across various industries.view Unlocking Creativity: Exploring the World of CNC Acrylic MachiningNovember 15, 2023Welcome to the realm where precision meets creativity, where the art of CNC (Computer Numerical Control) technology converges with the transparent beauty of acrylic. In this journey, we will delve into the intricate world of CNC Acrylic machining, unveiling its applications, design inspirations, material synergies, and real-world case studies.view

Unlocking Creativity: Exploring the World of CNC Acrylic MachiningNovember 15, 2023Welcome to the realm where precision meets creativity, where the art of CNC (Computer Numerical Control) technology converges with the transparent beauty of acrylic. In this journey, we will delve into the intricate world of CNC Acrylic machining, unveiling its applications, design inspirations, material synergies, and real-world case studies.view What are Corrosion Resistant Alloys?November 23, 2023Corrosion-resistant alloys are metallic materials that have the ability to resist media attack, and they are widely used in a variety of industries, especially in chemical processing, energy, marine, and aerospace, to provide reliable performance and safety.view

What are Corrosion Resistant Alloys?November 23, 2023Corrosion-resistant alloys are metallic materials that have the ability to resist media attack, and they are widely used in a variety of industries, especially in chemical processing, energy, marine, and aerospace, to provide reliable performance and safety.view 1018 vs. 4140 Steel: How to Choose the Right MaterialNovember 28, 2023Steel is one of the most widely used materials in various industries, such as construction, automotive, aerospace, and manufacturing. However, steel is also susceptible to corrosion and rust when exposed to moisture and oxygen.view

1018 vs. 4140 Steel: How to Choose the Right MaterialNovember 28, 2023Steel is one of the most widely used materials in various industries, such as construction, automotive, aerospace, and manufacturing. However, steel is also susceptible to corrosion and rust when exposed to moisture and oxygen.view What Is CNC Cutting? Unlocking the World of Precision MachiningNovember 2, 2023Are you intrigued by the world of precision manufacturing and curious about the fascinating technology behind it? If so, you've come to the right place. In this comprehensive guide, I'll take you on a journey through the realm of CNC Cutting, revealing its inner workings, diverse applications, and future trends.view

What Is CNC Cutting? Unlocking the World of Precision MachiningNovember 2, 2023Are you intrigued by the world of precision manufacturing and curious about the fascinating technology behind it? If so, you've come to the right place. In this comprehensive guide, I'll take you on a journey through the realm of CNC Cutting, revealing its inner workings, diverse applications, and future trends.view