Overview: This report provides an in-depth analysis of the development trends, competitive landscape, and key characteristics of China's rubber molds and parts industry in 2023. It serves as an important guide for procurement professionals to understand the latest market dynamics.

According to the latest "2023 Research Report on China's Rubber Mold Industry" released by the China Rubber Industry Association, in the complex global economic environment of 2022, China's rubber mold industry maintained a stable development trend. The annual rubber mold output is expected to reach 1.2 million tons, up 5% year-on-year. Among them, the tire mold output is about 900,000 tons, up 4%; industrial rubber product mold output is about 300,000 tons, up 6%.

The report points out that China has become the world's largest producer and exporter of rubber molds. In 2021, China's rubber mold exports reached US$2.3 billion. However, from the perspective of global market share, China's rubber mold exports accounted for only 18.9% of the total global rubber mold exports in 2021. This indicates that there is still considerable room for growth in exports for China's rubber mold industry.

When sourcing, it is advisable to select suppliers with large-scale production capabilities and automated production lines. Take Zhejiang Aoki Rubber & Plastic Technology Co. Ltd. for example, the company uses imported automated production lines from Germany, with an annual production capacity of 50,000 sets of tire molds. Their products are widely used by renowned tire companies like Michelin and Goodyear, with a product qualification rate up to 99%. Choosing these types of suppliers ensures not only quality assurance, but also access to large-scale production capacity.

Apart from production capacity considerations, specialization is also key when selecting suppliers. For industrial rubber product molds, it is recommended to choose suppliers with long-term expertise in specific industrial fields. For instance, Goertek uses Shenzhen Huichuan Precision Molds Co. Ltd. as its long-term supplier for rubber shoe sole molds, as the latter has over 10 years of R&D experience specializing in sport shoe sole molds. Opting for specialized suppliers provides support in design, quality and other aspects.

1. Early Stage (early-mid 20th century) - The industry first emerged in the 1900s when China mainly relied on imported rubber products and had weak R&D and manufacturing capabilities. Demand for molds and parts gradually increased with industrialization.

2. Infrastructure Building (mid 20th century-1980s) - China began focusing on developing the rubber industry. Government investment in manufacturing facilities drove preliminary growth despite technical and quality challenges. Domestic manufacturing made progress.

3. Reform and Opening Up (late 1980s-early 21st century) - The industry saw rapid expansion as advanced technologies and equipment were introduced. International cooperation improved innovation and quality. Many foreign firms entered the Chinese market, driving internationalization.

4. Technical Upgrading (early 21st century-present) - The industry has gradually achieved technical upgrades and innovation, transitioning from traditional to digital and smart manufacturing, enabling high-quality development. Applications in automotive, electronics, medical devices, etc. continue to expand.

5. Sustainable Development (future outlook) - Future development will focus on sustainability, eco-friendly materials and renewable energy to reduce environmental impact. Smart manufacturing will further enhance efficiency and quality.

The rubber molds and parts market in China continues to grow steadily. With the development of manufacturing and push for technological innovation, demand for rubber molds and parts is gradually increasing. From automotive parts to home appliance components, rubber molds and parts have extensive applications across various industries. According to market research, this market is expected to maintain stable growth over the next few years.

Technological innovation strongly drives industry development. Introduction of new materials, advanced production processes, and digital manufacturing are changing the landscape. Manufacturers continually seek more efficient and reliable production methods to meet evolving market demand.

The market has intense competition currently. Some reputable manufacturers hold important market positions, thriving by providing high-quality products and service. Meanwhile, some emerging companies are gaining traction, injecting new vitality into the market.

Various factors jointly promote market growth. Rising consumer demand for product quality and performance compels manufacturers to keep improving product design and manufacturing techniques. Additionally, supportive industrial policies and open international trade create favorable conditions for development.

The market is expected to maintain growth over the next few years. With the introduction of new technologies and shifting market demand, the industry will continue to evolve. Digital manufacturing, eco-friendly materials, and smart manufacturing are projected to be major future trends.

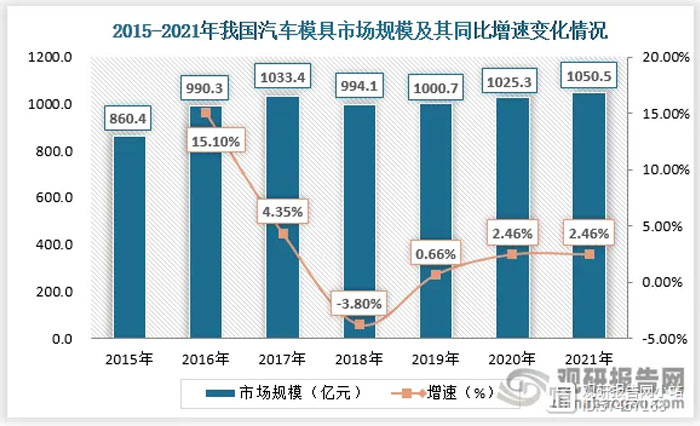

The market size of China's rubber mold industry is expected to maintain steady growth, closely related to the push of technological innovation and market demand. Based on market research and industry analysis, here are the forecasts for the market size and growth rate of China's rubber mold industry in 2023:

Market Size Forecast: In 2023, the market size of China’s rubber mold industry is projected to reach tens of billions of RMB. With the increasing demand for rubber molds across various sectors, the market size will continue to expand steadily. Applications in automotive, electronics, medical and other industries will keep driving market growth.

Growth Rate Forecast: In 2023, the growth rate of China’s rubber mold industry is expected to remain at a moderate level. Although the industry has achieved significant development in recent years, as market saturation gradually increases, the growth rate may stabilize relatively. However, factors like technological innovation, digitalization, and sustainability will inject new momentum into the industry.

Influencing Factors Analysis: The realization of market size and growth is affected by multiple factors. Rising consumer demand for product quality and performance drives manufacturers to continuously improve rubber mold design and manufacturing techniques. Supportive industrial policies, open international trade, and technological innovation will also positively impact market development.

Industry Trend Outlook: In the future, China’s rubber mold industry will face the impact of multiple trends. Application of digital manufacturing will enhance production efficiency and product quality, smart manufacturing will become a key direction. Adoption of eco-friendly materials will be promoted to reduce environmental impact. Additionally, indigenous innovation and international collaboration will further propel industry development.

The regional distribution in China's rubber mould industry shows a diversified trend, with different regions playing important roles in the industry's development. Here is an overview of the regional distribution in China's rubber mould industry in 2023:

▶ East China Region:

East China has long been one of the important manufacturing bases for the rubber mould industry in China. The region has a developed manufacturing and supply chain system, attracting many rubber mould manufacturers. Provinces like Shanghai, Jiangsu and Zhejiang have significant advantages in rubber mould manufacturing, technological innovation and market expansion.

▶ South China Region:

South China is also a major manufacturing center for the rubber mould industry in China. Provinces like Guangdong and Guangxi have rich experience and technical capabilities in rubber mould manufacturing. Manufacturers in this region are usually strong in export businesses and maintain close ties with international markets.

▶ North China Region:

Cities in North China like Beijing and Tianjin also have a place in the rubber mould manufacturing field. Although relatively smaller in scale compared to other regions, they still possess certain technical capabilities and market share.

▶ Western Region:

Although the western region accounts for a relatively small share in the rubber mould industry, some western provinces have started actively developing the rubber mould industry with policy support and investment guidance from the state. This helps promote balanced regional development and drives the manufacturing industry inland.

▶ Northeast Region:

The northeast region is also making efforts to revitalize manufacturing. The rubber mould industry is gradually emerging in this process. Provinces like Jilin and Liaoning have made some achievements in rubber mould manufacturing, playing a positive role in adjusting the regional industrial structure.

▶ Central Region:

The central region is also increasing support for the development of the rubber mould industry. Provinces like Hubei and Hunan have made some progress in manufacturing and technological innovation, gradually becoming an emerging force in the rubber mould industry.

The competitive landscape in China's rubber mould industry will continue to evolve, influenced by factors like technological innovation, market demand, as well as domestic and international market conditions. Below is an overview of the changes in the competitive landscape in China's rubber mould industry in 2023:

▶ Rise of Technological Leaders:

With continuous technological advancement, companies with advanced technologies and innovation capabilities will gain competitive advantages. They can design and manufacture high-quality, high-precision rubber moulds to meet customers' needs for sophisticated and customized products. These companies often enjoy good reputation in the industry, attracting more customers and partners.

▶ Intensified International Competition:

China's rubber mould industry has gradually stepped onto the international stage. More and more international manufacturers will enter the Chinese market, intensifying market competition and pushing domestic companies to continuously improve product quality and service to gain a foothold in the competition.

▶ Smart Manufacturing and Digital Transformation:

With the widespread application of smart manufacturing technologies, companies will march towards digital transformation. Companies capable of achieving smart manufacturing, digital design and production will be able to respond to market demand faster, improve production efficiency, lower costs, and thus gain competitive advantages.

▶ Supply Chain Optimization and Collaboration:

With the growing importance of supply chains, companies will place more emphasis on supply chain optimization and collaboration. Establishing robust collaborative relationships with high-quality suppliers can ensure stable and quality raw material supply. Efficient supply chain collaboration will also enhance corporate competitiveness.

▶ Green and Sustainable Development:

The rising awareness of environmental protection will influence the competitive landscape in the rubber mould industry. Companies adopting eco-friendly materials and reducing resource waste will be more easily recognized by the market and consumers. Under the context of sustainable development, environmental factors will become part of corporate competitiveness.

▶ Rise of Emerging Markets:

With the growth of emerging industries, demand for rubber moulds will also gradually increase. The rise of new industries like new energy vehicles and smart homes will bring new market opportunities for the rubber mould industry. Companies capable of flexibly responding to changes in market demand will be more likely to stand out in the competition.

Below is a case study of a typical successful company in China's rubber mould industry in 2023:

Company Name: Innovative Rubber Technology Co., Ltd.

Company Background: Founded in 2005 and headquartered in Shanghai, Innovative Rubber Technology specializes in the design, manufacturing and sales of rubber moulds, and is one of the well-known companies in China's rubber mould industry. Over the years, the company has been committed to technological innovation and quality improvement, earning wide recognition from customers and the market.

Technological Innovation: Innovative Rubber Technology continuously carries out technological innovation in the rubber mould field. The company has a strong R&D team that keeps developing new mould designs and manufacturing technologies. They actively apply advanced technologies like digital design and smart manufacturing to improve product precision and production efficiency.

High-quality Products: The company emphasizes product quality by implementing rigorous quality control processes to ensure products meet high standards. They choose premium materials and adopt advanced processing techniques to ensure product durability and stability. This gives their products a good reputation on the market.

International Cooperation: Innovative Rubber Technology collaborates with renowned international companies to expand the international market. They actively participate in international rubber mould exhibitions and exchange events to enhance the brand's international influence. Meanwhile, they also introduce advanced foreign production technologies and management expertise.

Green and Eco-friendly: The company values environmental protection by adopting eco-friendly materials and processes in product design and manufacturing. They actively respond to national environmental policies and are committed to reducing the environmental impact of production, providing customers with products that meet environmental standards.

Customer Service: Innovative Rubber Technology focuses on customer needs by providing customized solutions. They have established close cooperative relationships with customers, listening to customer feedback and suggestions to continuously optimize products and services.

Future Outlook: Through continuous technological innovation and market expansion, Innovative Rubber Technology Co., Ltd. will continue to maintain its leading position. The company will further promote smart manufacturing and digital transformation, actively respond to market changes, and provide customers with higher-quality products and services.

Through this case study, we can see the development path and success factors of a typical company in China's rubber mould industry in 2023. Innovation, quality, international cooperation, environmental awareness, and customer service are all important factors contributing to their success.

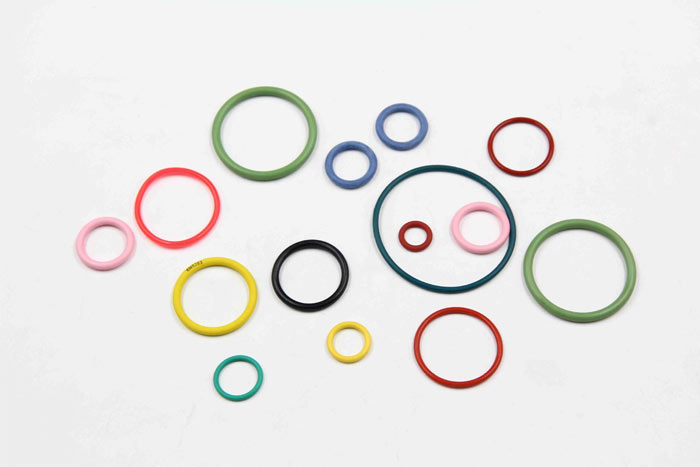

In 2023, China's rubber parts industry will continue to play an important role in meeting the needs of various industries across all major application areas. Below is an analysis of the market conditions in the major application areas of China's rubber parts industry in 2023:

◆ Automotive Industry:

The automotive industry has always been one of the most important application areas for China's rubber parts industry. With the development of new energy vehicles, autonomous driving, etc., the demand for rubber parts keeps increasing. For example, rubber seals, suspension systems, tires and other components play vital roles in automobile manufacturing.

◆ Electronics Industry:

With the continuous popularity of electronic products, the application of rubber parts in the electronics industry is also expanding. For instance, rubber seals, buttons, shock absorbers and other parts are often needed in electronic products like mobile phones, tablets and TVs to ensure product performance and stability.

◆ Medical Industry:

In the manufacturing of medical devices and equipment, rubber parts also play a significant role. For example, rubber pipes, seals, hoses and other parts are widely used in medical devices to ensure safety and reliability.

◆ Engineering Machinery:

The engineering machinery industry also has considerable demand for rubber parts, such as vibration dampers, hydraulic seals, etc. These parts play important roles in improving machinery performance, reducing noise and vibration.

◆ Appliance Industry:

Some home appliances like washing machines, refrigerators and air conditioners also need rubber parts to ensure normal operation and lifespan. Seals and shock absorbers are common rubber parts.

◆ Energy and Environmental Protection Industry:

With the rise of energy and environmental awareness, the application of rubber parts in this field is also gradually increasing. For instance, wind turbines, solar equipment need rubber parts for sealing, shock absorption and other functions.

◆ Other Areas:

Apart from the major areas above, rubber parts are also used in aviation, construction, telecommunications and many other fields. With technological advances and changing social needs, the rubber parts industry will play significant roles in more and more areas.

In summary, in 2023, China's rubber parts industry will continue to have extensive market demand across various application areas. As different industries develop, rubber parts will play critical roles in meeting the needs of different domains.

The different categories in China's rubber parts industry demonstrate certain contrasts in terms of growth. Below is an analysis comparing the growth situations of different categories in China's rubber parts industry in 2023:

▶ Automotive Parts:

As a major application area of the rubber parts industry, automotive parts are expected to maintain stable growth in 2023. With the development of new energy vehicles, autonomous driving, etc., the demand for automotive parts keeps rising, especially the rubber parts market related to electric vehicles is likely to gain more opportunities.

▶ Electronic Parts:

With the popularity of electronic products, the application of rubber parts in the electronics industry will also maintain relatively rapid growth. The demand for rubber parts from sectors like mobile phones, tablets, and home appliances will increase, especially rubber parts with waterproof, dustproof and other features will receive more attention.

▶ Medical Parts:

In the manufacturing field of medical devices and equipment, the demand for rubber parts will continue to grow. With continuous advances in medical technology, the demand for rubber seals, hoses, pipes and other parts will keep rising to meet high standards and reliability requirements for medical devices.

▶ Engineering Machinery Parts:

The engineering machinery industry will also maintain a certain growth trend in demand for rubber parts. Components like vibration dampers and hydraulic seals play vital roles in improving machinery performance, so with more infrastructure construction and engineering projects, the demand for related parts will grow steadily.

▶ Home Appliance Parts:

For some home appliances like washing machines, refrigerators and air conditioners, the demand for rubber parts will remain relatively stable. With the increase of smart and functional home appliances, related demand for rubber parts will also increase to some extent.

▶ Parts for Emerging Areas:

In emerging areas like new energy, environmental protection, aerospace, etc., the demand for rubber parts will also demonstrate relatively fast growth trends. The development in these areas will bring new opportunities and challenges to the rubber parts industry.

China's rubber parts industry shows some differences between domestic and foreign companies in several aspects. Below is an analysis comparing domestic and foreign companies in China's rubber parts industry in 2023:

① Domestic Companies:

Market Understanding:

Domestic companies have a deeper understanding of the local Chinese market, able to grasp market demands and trends more accurately, and provide products and solutions that better fit local needs for customers.

Cooperative Relations:

Domestic companies have stable supply chain partnerships locally, allowing them to respond to market changes faster and ensure stable product supply.

Policy Support:

Domestic companies can obtain various government support and preferential policies, which facilitates corporate development and innovation.

② Foreign Companies:

Technical Advantages:

Foreign companies usually possess advanced technologies and management experience, which can introduce cutting-edge manufacturing technologies and processes to China's rubber parts industry, improving product quality and production efficiency.

International Market:

Foreign companies have broader international marketing channels and customer resources, which helps bring China's rubber parts to the global market and achieve worldwide business expansion.

Innovation Capabilities:

Foreign companies are stronger in R&D and innovation, bringing new product designs, manufacturing technologies and solutions.

③ Common Characteristics:

Competitiveness:

Both domestic and foreign companies need to maintain competitiveness, and continuously improve product quality, technology and service levels to stand out in market competition.

Cooperation Opportunities:

There are also cooperation opportunities between domestic and foreign companies. They can complement each other's strengths through technical cooperation, market expansion and other means, achieving mutual benefits.

Company Name: Rongchuang Rubber Technology Co., Ltd.

Overview of Production Capabilities: As one of the leading companies in China's rubber parts industry, Rongchuang Rubber Technology possesses advanced production equipment, rich production experience, and an excellent team, with strong production capabilities and competitiveness.

Advanced Equipment: The company has invested heavily in introducing world-leading production equipment, including CNC machine tools, injection molding machines, mold processing equipment, etc. These advanced equipment can meet the manufacturing needs of different types of rubber parts, ensuring high precision and stability of the products.

Production Process: In the production process of rubber parts, Rongchuang Rubber adopts a series of strict production processes and quality control procedures. From the selection of raw materials to the packaging of finished products, every link is strictly controlled to ensure the quality and performance of the products.

Independent R&D: The company has an innovative R&D team dedicated to the research and application of new materials and processes. They can customize solutions based on customer needs and provide innovative products that align with market trends.

Production Capacity: Rongchuang has very strong production capabilities, with annual capacity reaching millions of rubber parts. They can respond swiftly to market demand and ensure delivery of large-scale orders to meet customer needs.

Quality Assurance: The company emphasizes product quality, establishing strict quality control systems through ISO9001 and other certifications. Every production stage has professional personnel for inspection and monitoring to ensure products meet international standards.

Customer Service: Along with production capabilities, Rongchuang also focuses on cooperative relationships with customers, providing timely technical support and after-sales service to build close partnerships.

Through this introduction of a typical company, we can see how an enterprise with strong production capabilities in China's 2023 rubber parts industry continues to improve product quality and competitiveness by adopting advanced equipment, strict quality control, independent R&D, etc., in order to meet market demand.

In 2023, China's rubber molds and parts industry exhibits multiple significant characteristics. These characteristics not only reflect the development trends of the industry, but also promote the industry's continuous progress. Here is a detailed analysis of these characteristics:

With the continuous growth in demand, the production capacity of China's rubber molds and parts industry continues to expand in 2023. Many companies invest in expanding production bases and introducing advanced equipment to meet diversified market demand. Capacity expansion not only helps improve the stability of supply, but also enables faster delivery to customers, promoting the development of the whole industry.

Automation technologies are widely applied in the rubber molds and parts industry, with continuously improving automation levels. The introduction of automated production lines, intelligent robots and other equipment has effectively improved production efficiency and product quality. Automated production not only reduces labor costs, but also decreases errors caused by human operations, providing enterprises with a more stable and efficient production environment.

The brand concentration in China's rubber molds and parts industry is gradually strengthening. More and more companies realize the importance of brands in market competition and begin to focus on brand building and enhancement. Some well-known companies are gradually establishing good brand images in the market and improving market competitiveness through continuous innovation, high-quality products and premium services.

Companies in China's rubber molds and parts industry demonstrate increasingly stronger capabilities in design and R&D. With the diversification of market demand, companies actively invest in R&D and launch innovative products aligning with market trends and customer needs. The application of advanced design tools and technologies not only improves the design quality of products, but also accelerates the launch speed of new products.

As a purchaser, there are several key suggestions that can help you cooperate better with suppliers and ensure the quality and delivery of products meet expectations when selecting rubber molds and parts suppliers, conducting quality control, and establishing cooperative models:

Comprehensive capability assessment: When selecting suppliers, do not only consider the price factor, but also comprehensively evaluate their production capacity, technical level, equipment advancement, etc. Choosing suppliers with stable production capacity and technical strength can ensure product quality and delivery.

Brand reputation verification: Understand the supplier's brand reputation and market feedback by inquiring customer reviews, industry reputation, etc. Choosing suppliers with a good reputation helps avoid potential risks.

Clear acceptance criteria: Before cooperating with suppliers, make clear the quality acceptance criteria for products to ensure both parties reach consensus on product quality requirements. Establishing clear quality standards can effectively reduce the risk of quality disputes.

Quality sampling mechanism: Establish a quality sampling mechanism to regularly select samples from batches for testing. Sampling can ensure stable product quality and early discovery of potential quality issues.

Long-term cooperation: It is recommended to establish long-term cooperative relationships with suppliers for common development. Long-term cooperation can promote mutual trust, and suppliers will also be more motivated to provide better services and products.- Information sharing: Maintain timely communication and information sharing with suppliers during cooperation. Sharing market information, demand changes, etc. can help suppliers better meet your needs.

Risk management: It is advisable to formulate cooperation agreements to clarify the rights and obligations of both parties. The agreement can stipulate the supplier's compensation responsibilities and risk taking to deal with potential risks.

In summary, purchasers need to consider supplier selection, quality control, and cooperation models prudently. Clear acceptance criteria, quality control mechanisms, and good cooperative relationships all contribute to smoother cooperation and ensure the quality and delivery of purchased rubber molds and parts meet expected goals.

A: Rubber molds and parts have applications in multiple fields, including automobile manufacturing, home appliance production, medical equipment, etc. These areas have sustained demands for high-quality rubber products.

A: Technological innovation can improve product quality and production efficiency, enabling manufacturers to meet the ever-changing market demands. Meanwhile, technological innovation also helps lower production costs and enhance corporate competitiveness.

A: The market competition landscape is impacted by various factors, including quality, pricing, service, etc. Well-known brands and technologically leading manufacturers are usually able to dominate the market.

A: Future development trends include digital manufacturing, application of green and eco-friendly materials, popularity of intelligent manufacturing technologies, etc. These trends will drive the industry toward more efficient and sustainable directions.

A: Choosing suitable suppliers requires considering various factors, including product quality, on-time delivery, after-sales service, etc. It is advisable for purchasers to conduct thorough market research and supplier assessments.

A: Market changes are inevitable. Formulating flexible procurement strategies is key to coping with changes. Maintain close cooperation with suppliers, pay attention to industry trends, and adjust procurement plans in a timely manner.

A: Rubber mold prices vary due to many factors. Different mold types, materials, sizes and manufacturing processes all impact the prices. Generally, prices of Chinese rubber molds are relatively competitive in the international market. The prices for molds of small parts are around $200.

A: Rubber part prices vary due to many factors. Different part types, materials, specifications and manufacturing processes all impact the prices. Generally, prices of Chinese rubber parts are relatively competitive in the international market. The prices for small rubber parts are around $2.

A: According to the latest market speed in China, the lead time is about 2 weeks, which means it takes 2 weeks from order placement to sample part production.

The Chinese rubber molds and parts industry is in a period of rapid growth. It has high competitiveness in terms of both technological capabilities and supply chain capabilities. Social stability, reliable quality, and on-time delivery are the long-standing advantages accumulated in the Chinese rubber molds and parts industry.

References:

1. 《2023 China Rubber Mold Industry Research Report》 模具行业分析报告_中国模具行业发展前景预测与投资战略规划分析报告-前瞻产业研究院

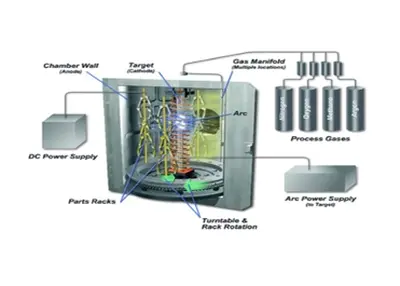

The Role of Custom PVD Coating in Industrial ApplicationsJanuary 5, 2024In today's fast-paced industrial world, companies are constantly seeking ways to enhance the performance and durability of their products. One effective method that has gained popularity is custom...view

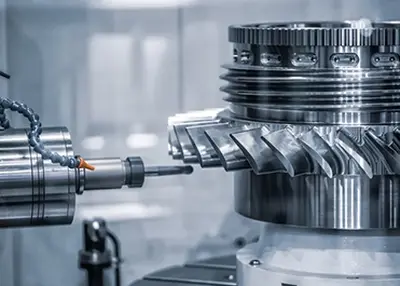

The Role of Custom PVD Coating in Industrial ApplicationsJanuary 5, 2024In today's fast-paced industrial world, companies are constantly seeking ways to enhance the performance and durability of their products. One effective method that has gained popularity is custom...view Machining process of connecting rod partsNovember 16, 2023Connecting rod parts play a vital role in the mechanical field and are commonly used in engines, vehicle drivelines, industrial machinery and other applications. In order to ensure their accuracy, reliability and performance, the manufacture of connecting rod parts needs to go through several machining processes.view

Machining process of connecting rod partsNovember 16, 2023Connecting rod parts play a vital role in the mechanical field and are commonly used in engines, vehicle drivelines, industrial machinery and other applications. In order to ensure their accuracy, reliability and performance, the manufacture of connecting rod parts needs to go through several machining processes.view Why Motorcycle Parts Using CNC Machining?October 25, 2023Two-wheeled vehicles motorcycles are more prone to accidents than four-wheeled vehicles. In case of an accident, the motorcycle parts get damaged and these damaged parts need to be replaced if you want to continue enjoying your motorcycle.view

Why Motorcycle Parts Using CNC Machining?October 25, 2023Two-wheeled vehicles motorcycles are more prone to accidents than four-wheeled vehicles. In case of an accident, the motorcycle parts get damaged and these damaged parts need to be replaced if you want to continue enjoying your motorcycle.view CNC Machining Titanium: Precision Craftsmanship and ApplicationsNovember 6, 2023Are you ready to dive into the world of CNC machining titanium? If you're an engineer, designer, or manufacturer seeking to master the art of CNC machining this remarkable metal, you've come to the right place. In this article, I will guide you through the intricacies of CNC machining titanium, offering valuable insights, best practices, and real-world applications.view

CNC Machining Titanium: Precision Craftsmanship and ApplicationsNovember 6, 2023Are you ready to dive into the world of CNC machining titanium? If you're an engineer, designer, or manufacturer seeking to master the art of CNC machining this remarkable metal, you've come to the right place. In this article, I will guide you through the intricacies of CNC machining titanium, offering valuable insights, best practices, and real-world applications.view Difference Between Hot Rolled and Cold RolledDecember 4, 2023Steel comes in a variety of grades, sizes, shapes and finishes - the World Steel Association lists more than 3,500 different grades of steel, most with unique properties. The variety of steel grades means that steel can be used in a wide range of applications for foundations, appliances, vehicles, wind turbines and many more.view

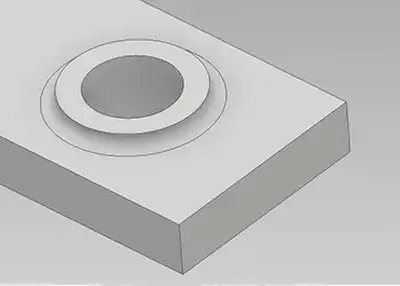

Difference Between Hot Rolled and Cold RolledDecember 4, 2023Steel comes in a variety of grades, sizes, shapes and finishes - the World Steel Association lists more than 3,500 different grades of steel, most with unique properties. The variety of steel grades means that steel can be used in a wide range of applications for foundations, appliances, vehicles, wind turbines and many more.view What is a Machined Boss: A Comprehensive GuideNovember 8, 2023In the world of precision engineering, the term machined boss may not be a household name, but it is undoubtedly a crucial element that underpins countless industries. Whether you're a novice looking to expand your knowledge or a seasoned professional seeking in-depth insights, this article will serve as your comprehensive guide to understanding what a machined boss is, how it works, and why it matters.view

What is a Machined Boss: A Comprehensive GuideNovember 8, 2023In the world of precision engineering, the term machined boss may not be a household name, but it is undoubtedly a crucial element that underpins countless industries. Whether you're a novice looking to expand your knowledge or a seasoned professional seeking in-depth insights, this article will serve as your comprehensive guide to understanding what a machined boss is, how it works, and why it matters.view