Precision mold making is a crucial process that requires specialized skills, knowledge, and tools. It involves the creation of tools that are used to produce other parts or products. The quality of the mold directly affects the quality of the final product, making it essential to use the right processes and techniques to achieve high precision and accuracy. In this article, we will explore the key points of precision mold making, including its processes, techniques, and tools.

Precision mold making is a complex and demanding process that requires careful attention to detail and expertise. It involves creating molds that are used to produce other parts or products with high accuracy and precision. The quality of the mold directly affects the quality of the final product, making it essential to use the right processes and techniques to achieve high precision and accuracy.

Precision mold making is essential for producing high-quality products that meet specific requirements. The process involves creating molds that are used to produce other parts or products with high accuracy and precision. The quality of the mold directly affects the quality of the final product, making it essential to use the right processes and techniques to achieve high precision and accuracy.

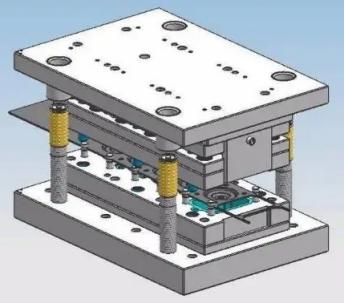

The process of precision mold making involves several steps, including design, material selection, tooling, machining, and finishing. Each step requires specialized skills, knowledge, and tools to achieve high precision and accuracy.

The design of the mold is the first step in the precision mold making process. It involves creating a blueprint or 3D model of the mold, which includes all the details and specifications of the final product. The design should be accurate and precise to ensure that the mold produces high-quality products.

The selection of the material is another critical step in the precision mold making process. The material used should be durable, strong, and resistant to wear and tear. Common materials used in precision mold making include steel, aluminum, and plastic.

The tooling process involves creating the tools that are used to produce the mold. It includes cutting, shaping, and drilling the material to create the desired shape and size. Tooling requires specialized skills and knowledge to ensure that the tools are created with high precision and accuracy.

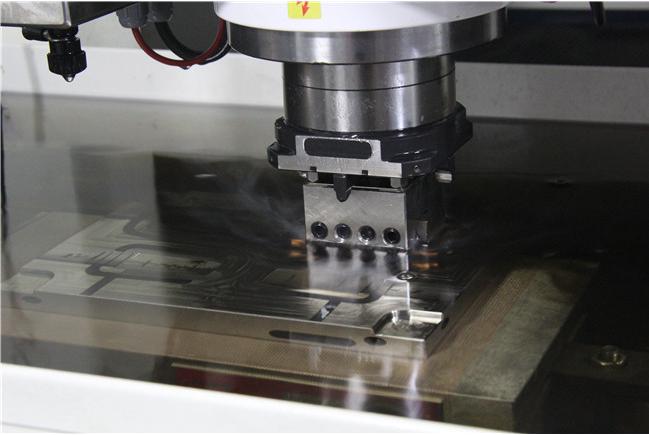

Machining involves using specialized machines to create the mold's final shape and size. It includes processes such as milling, drilling, and grinding to achieve high precision and accuracy. Machining requires specialized skills, knowledge, and tools to ensure that the final product meets the desired specifications.

The finishing process involves polishing and refining the mold's surface to achieve a smooth and

even finish. It helps to reduce friction and wear and tear and improve the mold's overall quality and durability.

Precision mold making requires the use of several techniques to achieve high precision and accuracy. Some of the common techniques used include:

EDM (Electrical Discharge Machining) is a technique used to create intricate shapes and designs in the mold. It involves using a high-voltage electrical discharge to erode the material and create the desired shape and size.

CNC (Computer Numerical Control) machining is a technique used to create complex shapes and designs with high precision and accuracy. It involves using a computer-controlled machine to cut, shape, and drill the material to create the desired shape and size.

Wire cutting is a technique used to cut complex shapes and designs in the mold. It involves using a thin wire to erode the material and create the desired shape and size.

Precision mold making requires the use of specialized tools to achieve high precision and accuracy. Some of the common tools used include:

CNC machines are computer-controlled machines that are used to cut, shape, and drill the material with high precision and accuracy. They are essential in precision mold making as they can create complex shapes and designs that are difficult to achieve manually.

EDM machines are specialized machines that use electrical discharges to erode the material and create intricate shapes and designs with high precision and accuracy. They are commonly used in precision mold making for creating complex shapes and designs.

Grinding machines are used to refine the surface of the mold and achieve a smooth and even finish. They are essential in precision mold making as they can help to reduce friction and wear and tear and improve the mold's overall quality and durability.

Cutting tools such as drills, end mills, and reamers are used to cut and shape the material to create the desired shape and size of the mold. They are essential in precision mold making as they can achieve high precision and accuracy in cutting and shaping the material.

Precision mold making is a complex and demanding process that requires specialized skills, knowledge, and tools. The quality of the mold directly affects the quality of the final product, making it essential to use the right processes and techniques to achieve high precision and accuracy. By following the key points of precision mold making, manufacturers can produce high-quality products that meet specific requirements.

1.What is precision mold making? Precision mold making is the process of creating molds that are used to produce other parts or products with high accuracy and precision.

2.Why is precision mold making important? Precision mold making is essential for producing high-quality products that meet specific requirements. The quality of the mold directly affects the quality of the final product.

3.What are the key points of precision mold making? The key points of precision mold making include design, material selection, tooling, machining, and finishing.

4.What are the common techniques used in precision mold making? Common techniques used in precision mold making include EDM, CNC machining, and wire cutting.

5.What are the common tools used in precision mold making? Common tools used in precision mold making include CNC machines, EDM machines, grinding machines, and cutting tools.

CNC Machining and AI: How Artificial Intelligence is Impacting the FieldOctober 25, 2023Artificial Intelligence is having a profound impact on CNC machining services, transforming operations and delivering many benefits. Here are some of the key areas where AI is playing a major role:view

CNC Machining and AI: How Artificial Intelligence is Impacting the FieldOctober 25, 2023Artificial Intelligence is having a profound impact on CNC machining services, transforming operations and delivering many benefits. Here are some of the key areas where AI is playing a major role:view The Purpose and Importance of Metal Surface FinishApril 4, 2023Nowadays, metal surface finish technology is applied in many fields, which brings about innovation in metal surface finish and oil stain cleaning technology. Metal surface finish pretreatment is an in...view

The Purpose and Importance of Metal Surface FinishApril 4, 2023Nowadays, metal surface finish technology is applied in many fields, which brings about innovation in metal surface finish and oil stain cleaning technology. Metal surface finish pretreatment is an in...view Different Types of Bearings: Their Distinctive Features and Diverse UsesMay 28, 2024Learn about the importance of mechanical bearings, different types, and how to choose the right one for your needs. Explore applications in various fields and factors to consider for smooth and precise motions.view

Different Types of Bearings: Their Distinctive Features and Diverse UsesMay 28, 2024Learn about the importance of mechanical bearings, different types, and how to choose the right one for your needs. Explore applications in various fields and factors to consider for smooth and precise motions.view How to Use a Five Axis Machining Center to Process Titanium Alloy Shaped PartsMarch 24, 2023As a five-axis machining center engineer, I will share with you the methods of machining titanium alloy special-shaped parts using a five-axis machining center, as well as the key points of titanium a...view

How to Use a Five Axis Machining Center to Process Titanium Alloy Shaped PartsMarch 24, 2023As a five-axis machining center engineer, I will share with you the methods of machining titanium alloy special-shaped parts using a five-axis machining center, as well as the key points of titanium a...view CNC Machining Titanium: Precision Craftsmanship and ApplicationsNovember 6, 2023Are you ready to dive into the world of CNC machining titanium? If you're an engineer, designer, or manufacturer seeking to master the art of CNC machining this remarkable metal, you've come to the right place. In this article, I will guide you through the intricacies of CNC machining titanium, offering valuable insights, best practices, and real-world applications.view

CNC Machining Titanium: Precision Craftsmanship and ApplicationsNovember 6, 2023Are you ready to dive into the world of CNC machining titanium? If you're an engineer, designer, or manufacturer seeking to master the art of CNC machining this remarkable metal, you've come to the right place. In this article, I will guide you through the intricacies of CNC machining titanium, offering valuable insights, best practices, and real-world applications.view How to Go About Choosing an Aluminum Alloy Mechanical Keyboard Shell Processing Manufacturer?October 26, 2023For computer enthusiasts, the mechanical keyboard's metal texture and the sound of that mechanical equipment is a keyboard users a kind of enjoyment, mechanical keyboard bezel styling design is one of my favorite hardware configurations, especially glazed, computer typing is very indulgent.view

How to Go About Choosing an Aluminum Alloy Mechanical Keyboard Shell Processing Manufacturer?October 26, 2023For computer enthusiasts, the mechanical keyboard's metal texture and the sound of that mechanical equipment is a keyboard users a kind of enjoyment, mechanical keyboard bezel styling design is one of my favorite hardware configurations, especially glazed, computer typing is very indulgent.view

EN

EN

ru

ru