CNC machining is a precise manufacturing process that is controlled by computers. It involves using computer programs to control the movement of cutting tools, which remove material from a workpiece to create a finished part. This process can be used to produce parts and components made from various materials such as metal, plastic, and others. This article explains the different types of CNC machines and how they function.

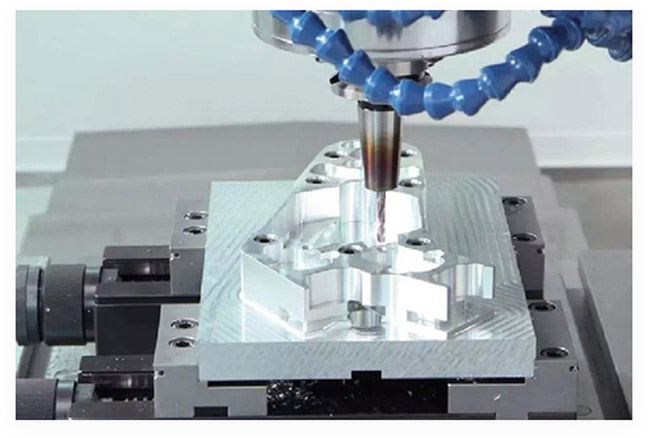

The milling CNC machine is a tool that uses rotating cutting tools to shape and cut solid materials such as metal, wood, or plastic. These tools can be oriented horizontally or vertically and include end mills, helical mills, and chamfer mills. The CNC milling process involves the use of CNC-enabled milling machinery, also known as mill machines or mills, which can have three-axis movements or more advanced models with additional axes. There are different types of milling machines available, including hand, plain, universal, and universal milling machines.

Richconn has a wide range of high-precision CNC milling machines. The milling ranges from 1mm to 1500mm shows that Richconn can handle various sizes of projects.

A router CNC machine is similar to a CNC mill but is primarily used for machining softer materials and may be less precise than CNC mills. CNC routers are characterized by their ability to use computer numerical control to design and shape materials like wood, steel, foam, composites, aluminum, and plastic. They consist of various components such as stepper motors, stepper drivers, a mechanical base, a spindle, controllers, and a power supply. CNC routers offer advantages such as waste reduction, increased productivity and accuracy, and faster production of products.

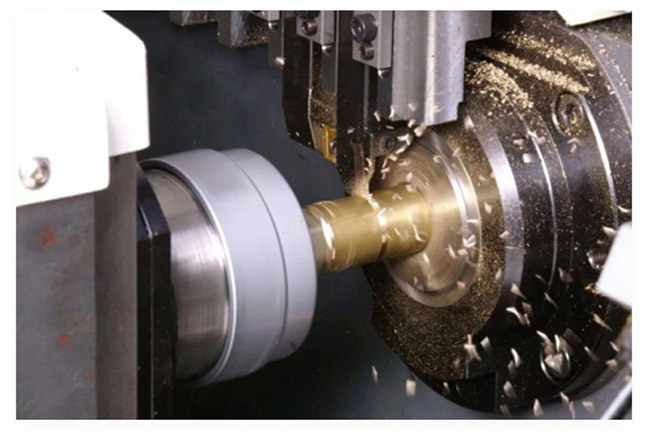

The CNC lathe is one of the types of CNC machine used for shaping cylindrical or symmetrical workpieces. It operates by rotating the workpiece while a cutting tool moves in different directions to remove material and shape the object. The turning tool used varies depending on the specific application, with options available for tasks such as roughing, finishing, facing, threading, forming, undercutting, parting, and grooving.

CNC (Computer Numerical Control) technology is used in the turning process, where CNC-enabled lathes or turning machines are employed. These include turret lathes, engine lathes, and special-purpose lathes.

Richconn has high-precision (± 0.002) digital lathe processing. The turning range is from 1mm to 1200mm. Richconn is experienced in machining of turning, such as shaft, rod, tube, and circular machining.

5-axis CNC machines are the advanced CNC machine types that add two rotational axes to the traditional machine tool's 3-axis linear motions (X, Y, Z). This allows the machine tool to access five out of six sides of a part in a single operation. By using a tilting, rotating work holding fixture or trunnion, the machine becomes a 3+2 or indexed machine, enabling the milling cutter to approach five sides of a prismatic workpiece at 90 degrees without the need for the operator to reset the workpiece. 5-axis CNC machines are often used for creating sculptures and other complex shapes.

The inclusion of 5-axis CNC machining services suggests that Richconn is equipped with advanced machinery and skilled technicians, enabling it to bring complex designs to life.

CNC Plasma Cutting Machines utilize a plasma torch to cut through materials. One requirement for CNC plasma cutting is that the material or workpiece being cut must be electrically conductive. Common materials used in plasma cutting include brass, copper, aluminum, steel, and stainless steel.

A CNC plasma cutting machine incorporates a high-powered torch capable of cutting even tough materials like titanium and steel. This torch is created by passing high-velocity gas through a nozzle, resulting in the formation of an electric arc. As the arc interacts with the material being cut, it transforms some of the high-velocity gas into plasma, an electronically ionized gas.

CNC wire EDM machines are unique types of CNC that use electric sparks to shape materials. The electrical discharge process has a transient effect and can degrade the elements it interacts with. These machines take advantage of this characteristic by generating controlled sparks to reshape the workpieces. The materials to be shaped are placed between the electrodes, and the computer determines the amount of electrical discharge the electrodes produce.

A 3D printer is a type of CNC machine. This machine works by printing elements layer-by-layer according to a design created through computer-aided design (CAD) and computer-aided manufacturing (CAM) processes. 3D printers are commonly used for prototyping.

To select the best CNC machine type, several factors need to be considered.

Material

You need to determine the CNC process you want to use and the materials you will be working with. Different CNC machines are designed for different processes and materials, so it is important to choose a machine that is compatible with your specific requirements.

Weight of the Machine

The key consideration is the weight of the machine. If you plan to move or transport the machine frequently, a lighter machine would be more suitable. On the other hand, if stability and durability are important for your applications, you may prefer a heavier machine.

Work Radius of the Machine

The work radius of the machine is an important factor to consider. It should be larger than the maximum area required for your products to ensure that the machine can accommodate your needs.

Speed of the Machine

The speed of the machine is another crucial consideration. Depending on your production requirements, you may need a machine with high-speed capabilities to enhance productivity.

Power Consumption

You should check the power consumption requirements of the machine. Depending on the type and specifications of the machine, you may need to increase the power availability in your workshop to cater to the machine's needs. It is essential to make the necessary adjustments to the power supply to ensure the machine operates smoothly.

What the different types of CNC machines are and how to select the best CNC machine type are some common questions that many unassociated with the industry ask. In this regard, Richconn is a reliable manufacturing partner that offers top-notch CNC machining solutions. Their expert team has the capabilities to produce parts with tight tolerances and provides services such as CNC turning, CNC milling, and more. If you are looking for the best CNC machined results, you can contact Richconn today.

Is NTPT Carbon Fiber A Gimmick or A Manifestation of Value?May 30, 2022When it comes to carbon fiber watches, we have to mention Audemars Piguet. Audemars Piguet is definitely the ancestor of carbon used in watches. In those days, bumblebees were hard to find. This is al...view

Is NTPT Carbon Fiber A Gimmick or A Manifestation of Value?May 30, 2022When it comes to carbon fiber watches, we have to mention Audemars Piguet. Audemars Piguet is definitely the ancestor of carbon used in watches. In those days, bumblebees were hard to find. This is al...view Surface Finishing Process What Are the Different Products Suitable For What Process?October 24, 2023The whole process of processing, in the selection of the appropriate processing method CNC processing or 3D printing, after the completion of processing, most of them need surface treatment. Meet the corrosion resistance, abrasion resistance, decoration or other special functional requirements of the product.view

Surface Finishing Process What Are the Different Products Suitable For What Process?October 24, 2023The whole process of processing, in the selection of the appropriate processing method CNC processing or 3D printing, after the completion of processing, most of them need surface treatment. Meet the corrosion resistance, abrasion resistance, decoration or other special functional requirements of the product.view Everything About Roller - Materials, Processing, ProductsJune 15, 2023In this era of rapid change, mechanical equipment is developing rapidly, the degree of automation and intelligence in production is continuously improving, and the performance indicators of mechanical...view

Everything About Roller - Materials, Processing, ProductsJune 15, 2023In this era of rapid change, mechanical equipment is developing rapidly, the degree of automation and intelligence in production is continuously improving, and the performance indicators of mechanical...view CNC Machining and Machined Wheels: Elevating Automotive ExcellenceNovember 7, 2023Are you ready to delve into the intricate world of CNC machining and its remarkable connection with machined wheels? As an automotive enthusiast and CNC machining professional, I'm thrilled to guide you through this comprehensive exploration of the dynamic interplay between precision engineering and high-performance wheels. Let's roll!view

CNC Machining and Machined Wheels: Elevating Automotive ExcellenceNovember 7, 2023Are you ready to delve into the intricate world of CNC machining and its remarkable connection with machined wheels? As an automotive enthusiast and CNC machining professional, I'm thrilled to guide you through this comprehensive exploration of the dynamic interplay between precision engineering and high-performance wheels. Let's roll!view The Features and Characteristics of CNC Milling MaterialsFebruary 29, 2024CNC milling, a cornerstone in the manufacturing processes of various industries, hinges significantly on the selection of materials.view

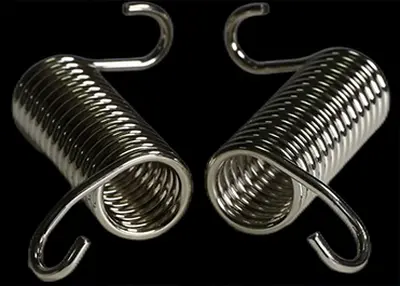

The Features and Characteristics of CNC Milling MaterialsFebruary 29, 2024CNC milling, a cornerstone in the manufacturing processes of various industries, hinges significantly on the selection of materials.view The Tiny World of Springs: A Comprehensive Analysis of Their Types and ApplicationsSeptember 26, 2023Springs are an extremely important and common component in mechanical parts, excelling in enabling motion, shock absorption, providing controllable pushing force, pulling force, and flexible clearance...view

The Tiny World of Springs: A Comprehensive Analysis of Their Types and ApplicationsSeptember 26, 2023Springs are an extremely important and common component in mechanical parts, excelling in enabling motion, shock absorption, providing controllable pushing force, pulling force, and flexible clearance...view

EN

EN

ru

ru