Stainless steel is the abbreviation of stainless and acid-resistant steel, air, steam, water and other weak corrosive media or with stainless steel is called stainless steel, and will be resistant to chemical corrosive media (acids, alkalis, salts and other chemical corrosion) corrosion of the steel is called acid-resistant steel. Because of the differences in the chemical composition of the two and their corrosion resistance is different, ordinary stainless steel is generally not resistant to chemical media corrosion, and acid-resistant steel are generally stainless. The following is a brief introduction to several commonly used stainless steel properties and applications:

Properties: 304 stainless steel is the most common type of steel, as a widely used steel, with good corrosion resistance, heat resistance, low temperature strength and mechanical properties; stamping, bending and other hot workability, no heat treatment hardening phenomenon (non-magnetic, ready to use the temperature -196 ℃ ~ 800 ℃).

Scope of application: household goods (1, 2 types of cutlery, cabinets, indoor plumbing, water heaters, boilers, bathtubs); automotive parts (windshield wipers, mufflers, molded products); medical equipment, building materials, chemical, food industry, agriculture, ship parts.

Properties: as a low carbon 304 steel, in the general state, its corrosion resistance is similar to 304 steel, but after welding or stress relief, its excellent resistance to grain boundary corrosion; in the absence of heat treatment, it can also maintain good corrosion resistance, the use of temperature -196 ℃ ~ 800 ℃.

Scope of application: Used in the chemical, coal and petroleum industries where high resistance to grain boundary corrosion is required for field and open-air machines, heat-resistant parts for building materials and parts that are difficult to heat-treat.

Properties: 316 stainless steel due to the addition of molybdenum, so its corrosion resistance, atmospheric corrosion resistance and high temperature strength is particularly good, can be used in harsh conditions; work hardening excellent (non-magnetic).

Scope of application: equipment for seawater, chemical, dyestuff, paper, oxalic acid, fertilizer and other production equipment; photography, food industry, coastal facilities, ropes, CD rods, bolts, nuts.

Why does stainless steel also rust? When the surface of the stainless steel tube appears brown rust spots (points), people are greatly surprised: that "stainless steel is not rust, rust is not stainless steel, may be a problem with the steel". In fact, this is a lack of understanding of stainless steel a one-sided wrong view. Stainless steel will rust under certain conditions.

Stainless steel has the ability to resist atmospheric oxidation - that is, stainless steel, but also has the ability to resist corrosion in the medium containing acid, alkali, salt - that is, corrosion resistance. But the size of its corrosion resistance is with the chemical composition of the steel itself, plus the state of protection, the use of conditions and the type of environmental media and change. Such as 304 steel pipe, in the dry and clean atmosphere, there is absolutely excellent corrosion resistance, but it will be moved to the seaside areas, in the sea spray containing a large amount of salt, will soon rust; and 316 steel pipe is a good performance. Therefore, it is not any kind of stainless steel that is resistant to corrosion and rust in any environment.

There are three main factors that affect the rusting of stainless steel:

1, the content of alloying elements generally speaking, the content of chromium in 10.5% steel is not easy to rust. The higher the content of chromium and nickel corrosion resistance is better, such as 304 material nickel content of 8-10%, chromium content of 18-20%, such stainless steel in general is not rust.

2, the production of smelting process smelting technology, advanced equipment, advanced technology, large stainless steel plant both in the control of alloying elements, the removal of impurities, billet cooling temperature control can be guaranteed, so the product quality is stable and reliable, good intrinsic quality, not easy to rust. On the contrary, some small steel plant equipment backward, backward technology, smelting process, impurities can not be removed, the production of products will inevitably rust.

3, the external environment of the climate is dry and well ventilated environment is not easy to rust, while the air humidity, continuous rainy weather, or air containing acidity and alkalinity of the environment is easy to rust. 304 material stainless steel, if the surrounding environment is too poor is also rusty.

1, chemical methods with pickling paste or spray to assist its corrosion parts to re-passivate the formation of chromium oxide film to restore its corrosion resistance, after pickling, in order to remove all the pollutants and acid residues, with water for proper rinsing is very important. After everything is processed and re-polished with polishing equipment, it can be closed with polishing wax. For localized slight rust spots can also be used 1:1 gasoline, oil mixture with a clean rag to wipe off the rust spots can be.

2, mechanical methods of sandblasting cleaning, cleaning with glass or ceramic particle blasting, obliteration, brushing and polishing. It is possible to wipe away contamination caused by previously removed materials, polishing materials or obliterated materials by mechanical means. All kinds of contamination, especially foreign iron particles, can be a source of corrosion, especially in humid environments. Therefore, mechanically cleaned surfaces should preferably be formally cleaned under dry conditions. The use of mechanical methods only cleans its surface and does not change the corrosion resistance of the material itself. It is therefore recommended to re-polish the surface with polishing equipment and seal it with polishing wax after mechanical cleaning.

Not only did we gain insight into the properties and applications of stainless steel, we also learned why even stainless steel may rust and how to deal with rust spots on stainless steel. The wide range of applications for stainless steel covers household, automotive, medical, construction, chemical, food and many others. Choosing the right stainless steel material is critical to ensuring the quality and durability of your products.

When you need precision stainless steel machining services, including CNC milling services and CNC turning services, Richconn is the company to call.Richconn is a precision machine works with state-of-the-art equipment and a dedicated team of professionals to meet the needs of a variety of industries. Whether you're in automotive manufacturing, medical devices, construction, or another industry, Richconn can provide you with high-quality stainless steel machining services that will ensure the performance and quality of your products.

The selection and maintenance of stainless steel is critical to many industries, as it provides excellent corrosion resistance in a variety of environmental conditions. Understanding the properties of stainless steel and how to deal with possible rust spots will help ensure the long-term reliability of your products.Richconn, as your trusted partner, will provide expert stainless steel CNC machining services to meet your every need for success in a variety of industries.

Brass vs Bronze vs Pure Copper vs Copper Alloys: An in-depth look at their differencesSeptember 26, 2023The comparison of brass to bronze to copper and its copper alloys is crucial as these metals can be easily confused. In addition, the distinction between these materials is also very subtle. As a result, development engineers or designers can be seriously confused when it comes to material selection. In particular, the similarity of these metal constituent elements makes it more difficult to classify and select them.view

Brass vs Bronze vs Pure Copper vs Copper Alloys: An in-depth look at their differencesSeptember 26, 2023The comparison of brass to bronze to copper and its copper alloys is crucial as these metals can be easily confused. In addition, the distinction between these materials is also very subtle. As a result, development engineers or designers can be seriously confused when it comes to material selection. In particular, the similarity of these metal constituent elements makes it more difficult to classify and select them.view Unlocking Precision: A Comprehensive Guide to Machining KeywaysNovember 15, 2023Welcome to the definitive guide on keyway machining, where precision meets performance. In this in-depth exploration, we will unravel the complexities of keyway machining, providing you with practical insights, expert tips, and real-world applications. Whether you're an engineer seeking mastery or an enthusiast eager to delve into the intricacies, this guide promises a thorough journey through the world of keyway machining.view

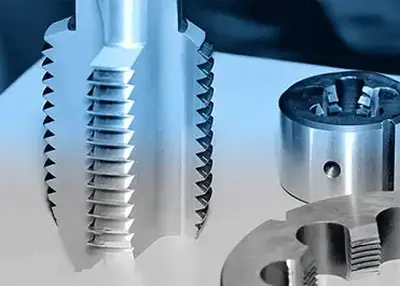

Unlocking Precision: A Comprehensive Guide to Machining KeywaysNovember 15, 2023Welcome to the definitive guide on keyway machining, where precision meets performance. In this in-depth exploration, we will unravel the complexities of keyway machining, providing you with practical insights, expert tips, and real-world applications. Whether you're an engineer seeking mastery or an enthusiast eager to delve into the intricacies, this guide promises a thorough journey through the world of keyway machining.view Exploring the Precision and Efficiency of CNC Tapping in MachiningNovember 22, 2023Precision in machining isn't just a goal; it's the essence that defines excellence. Within this realm, CNC tapping emerges as a beacon of accuracy, revolutionizing how threads are crafted and machines function. Let's delve deeper into this intricate world to uncover the precision and efficiency it offers.view

Exploring the Precision and Efficiency of CNC Tapping in MachiningNovember 22, 2023Precision in machining isn't just a goal; it's the essence that defines excellence. Within this realm, CNC tapping emerges as a beacon of accuracy, revolutionizing how threads are crafted and machines function. Let's delve deeper into this intricate world to uncover the precision and efficiency it offers.view Methods and Characteristics of Electrophoretic Metal CoatingJune 17, 2024Methods of Electrophoretic Metal CoatingDue to the different nature of electrophoretic metal coating itself, it is divided into two kinds: anodic electrophoretic metal coating and cathodic electrophor...view

Methods and Characteristics of Electrophoretic Metal CoatingJune 17, 2024Methods of Electrophoretic Metal CoatingDue to the different nature of electrophoretic metal coating itself, it is divided into two kinds: anodic electrophoretic metal coating and cathodic electrophor...view Tips On How to Find Low Cost CNC Milling ServicesOctober 24, 2023CNC milling services are not cheap. The more accurate the design you need, the more money you can expect to spend. Reliable machine shops employ professional operators who use state-of-the-art equipment to fulfill orders. As a result, you can't afford to ignore your budget in order to shorten lead times or gain a competitive edge.view

Tips On How to Find Low Cost CNC Milling ServicesOctober 24, 2023CNC milling services are not cheap. The more accurate the design you need, the more money you can expect to spend. Reliable machine shops employ professional operators who use state-of-the-art equipment to fulfill orders. As a result, you can't afford to ignore your budget in order to shorten lead times or gain a competitive edge.view Protect, Enhance, Beautify: The Versatility of Blackening Surface TreatmentsDecember 4, 2023Surface treatments play a vital role in maintaining and enhancing the durability and appearance of various materials. Whether it is for aesthetic purposes, rust prevention, or to improve wear resistan...view

Protect, Enhance, Beautify: The Versatility of Blackening Surface TreatmentsDecember 4, 2023Surface treatments play a vital role in maintaining and enhancing the durability and appearance of various materials. Whether it is for aesthetic purposes, rust prevention, or to improve wear resistan...view

EN

EN

ru

ru