In the world of precision engineering and manufacturing, CNC technology plays a pivotal role. Among the various CNC techniques, CNC POR stands out as a critical component, offering unmatched precision, efficiency, and versatility. If you're curious about CNC POR, you've come to the right place. This article will dissect CNC POR, exploring its fundamentals, applications, advantages, and much more. By the end, you'll have a profound understanding of this groundbreaking technology.

CNC POR, short for Computer Numerical Control Point of Rotation, is a sophisticated machining technology that revolutionizes the way we create intricate parts and components. Unlike traditional CNC systems, CNC POR focuses on the rotational movements of a workpiece, offering an unprecedented level of precision. This section will delve into the core concepts of CNC POR, helping you grasp its fundamental principles.

CNC POR revolves around the precise control of rotational movements. These movements are achieved through computer programming, which dictates the exact angles and speeds of rotation for a workpiece. The key components of CNC POR include:

Rotational Axis: CNC POR typically involves multi-axis rotations. The number of axes may vary depending on the complexity of the workpiece. These axes control the rotation of the workpiece in different directions.

Computer Control: A computer, often equipped with sophisticated software, processes the design data and translates it into precise commands for the rotational axes.

Cutting Tools: CNC POR machines are equipped with cutting tools, which are precisely positioned and rotated to create the desired shapes and features on the workpiece.

Feedback Systems: These systems provide real-time feedback to ensure accuracy. They may include encoders, sensors, and monitoring devices to correct any deviations.

Understanding these fundamentals is essential to comprehend the intricate precision that CNC POR brings to manufacturing processes.

Understanding the inner workings of CNC POR is essential to appreciate its capabilities fully. We'll break down the technology's operation, from the precise control of rotational movements to the integration of computer systems for real-time adjustments. You'll gain insights into how CNC POR stands out in the world of CNC machining.

CNC POR operates through a systematic workflow that ensures precision and accuracy in the machining process. Here's a step-by-step breakdown:

Design Input: The process begins with the input of a design into the CNC POR system. This design serves as the blueprint for the workpiece.

Toolpath Generation: The CNC software calculates the toolpaths required for the machining process. It determines the angles and speeds of rotation for each axis.

Material Setup: The workpiece is securely clamped in place, ready for machining. Fixturing and tooling are critical to ensure stability during rotation.

Machine Initialization: The CNC POR machine initializes the rotational axes and cutting tools, positioning them according to the programmed toolpaths.

Machining Process: The cutting tools are precisely controlled to create the desired shapes on the workpiece through rotational movements. This process continues until the entire workpiece is machined.

Quality Assurance: Feedback systems continuously monitor the process, making real-time adjustments if necessary to maintain precision.

Final Inspection: After machining, the workpiece undergoes a final inspection to ensure it meets the desired specifications.

By following this workflow, CNC POR achieves unparalleled accuracy in machining, making it a preferred choice for complex components.

The versatility of CNC POR knows no bounds. It finds applications in various industries, including aerospace, automotive, medical, and more. we'll explore real-world examples of how CNC POR is used to create complex components, showcasing its role in modern manufacturing.

Table 1: CNC POR Applications in Aerospace

| Industry Application | CNC POR Use |

|---|---|

| Aircraft Engine Parts | CNC POR ensures high precision in producing critical engine components, leading to improved engine efficiency and reliability. |

| Aerospace Prototyping | Rapid prototyping and production of aerospace components benefit from the rotational precision offered by CNC POR. |

| Satellite Technology | Rotational control is vital in creating satellite components, making CNC POR a go-to technology for the aerospace sector. |

The aerospace industry demands the highest levels of precision and reliability in component manufacturing. CNC POR delivers on these requirements by ensuring the precise machining of critical parts, contributing to the safety and performance of aircraft and space technology.

Table 2: CNC POR Applications in Automotive

| Industry Application | CNC POR Use |

|---|---|

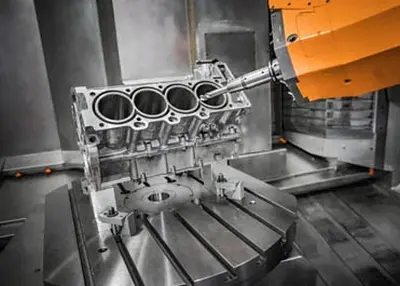

| High-Performance Engines | CNC POR technology is employed to craft precision parts for high-performance engines, enhancing power and efficiency. |

| Vehicle Prototyping | Prototyping and modeling in automotive design benefit from the rotational precision of CNC POR, enabling faster development cycles. |

| Custom Exhaust Systems | Custom exhaust systems require intricate bends and curves, which CNC POR can accomplish with unmatched precision. |

In the automotive sector, CNC POR plays a vital role in achieving top-notch performance and design. From crafting engine components to shaping custom exhaust systems, CNC POR technology enhances automotive engineering.

Table 3: CNC POR Applications in Medical

| Industry Application | CNC POR Use |

|---|---|

| Prosthetic Manufacturing | The production of custom prosthetics relies on CNC POR's ability to create highly individualized and intricate components. |

| Dental Implantology | Precision is paramount in dental implants. CNC POR ensures accurate manufacturing for the dental industry. |

| Medical Device Production | CNC POR contributes to the creation of advanced medical devices, from surgical instruments to imaging equipment. |

In the medical field, CNC POR's precision and customization capabilities make it indispensable. It aids in the development of prosthetics, dental implants, and various medical devices, improving the quality of life for patients.

These are just a few examples of how CNC POR technology is applied across different industries. Its adaptability and precision make it a cornerstone of modern manufacturing processes. Whether in aerospace, automotive, or healthcare, CNC POR plays a vital role in shaping the components and technology we rely on daily.

CNC POR isn't the only player in the CNC game. we'll compare CNC POR with traditional CNC technologies, highlighting its advantages in terms of precision and efficiency. By the end of this section, you'll know when and why to choose CNC POR over other options.

Table 4: Precision and Complexity Comparison

| Aspect | CNC POR | Traditional CNC |

|---|---|---|

| Precision | Unmatched rotational precision, suitable for intricate parts and complex geometries. | Precision is excellent but might vary depending on machine and setup. |

| Complexity | Well-suited for components with complex rotational features. | Better for parts with linear, straightforward machining needs. |

CNC POR stands out in terms of precision and is particularly well-suited for components that require complex rotational features. Traditional CNC is also precise but may not offer the same level of rotational control as CNC POR.

Table 5: Efficiency and Speed Comparison

| Aspect | CNC POR | Traditional CNC |

|---|---|---|

| Efficiency | Highly efficient due to simultaneous rotational control, reducing machining time. | Efficiency depends on machine setup and complexity of the part. |

| Speed | Faster for parts with rotational features. Ideal for intricate designs. | Generally faster for straightforward, linear machining requirements. |

CNC POR's simultaneous rotational control leads to increased efficiency, especially for parts with rotational features. Traditional CNC's speed depends on the nature of the part being machined.

Table 6: Versatility Comparison

| Aspect | CNC POR | Traditional CNC |

|---|---|---|

| Versatility | Extremely versatile for a wide range of parts, especially those with complex shapes. | Versatile for a broad array of machining tasks but may not excel with complex rotational features. |

CNC POR's versatility shines when it comes to parts with intricate and complex shapes. Traditional CNC is also versatile but may face challenges with intricate rotational features.

By comparing these aspects, it becomes clear that CNC POR offers distinct advantages when precision and efficiency are paramount. Its ability to control rotational movements with unmatched precision positions it as the go-to technology for components with complex geometric features.

What does the future hold for CNC POR? we'll examine market trends and growth projections for CNC POR technology. Whether you're a business owner or a technology enthusiast, you'll gain insights into the opportunities and potential disruptions in the CNC POR landscape.

Table 7: CNC POR Market Growth

| Aspect | CNC POR Market Growth |

|---|---|

| Growth Rate | The CNC POR market is expected to grow at a steady rate, with increasing demand for precision manufacturing. |

| Emerging Markets | Emerging markets, especially in Asia, are becoming significant consumers of CNC POR technology. |

| Technology Advancements | Continuous technological advancements in CNC POR equipment are driving market expansion. |

The CNC POR market is set to grow steadily, with a particular focus on precision manufacturing. Emerging markets, especially in Asia, are playing a crucial role in the increasing adoption of CNC POR technology. Moreover, ongoing technological advancements in CNC POR equipment are expected to fuel further market expansion.

Table 8: CNC POR Industry Applications

| Aspect | CNC POR Industry Applications |

|---|---|

| Aerospace | The aerospace industry is expected to remain a prominent user of CNC POR technology, ensuring high precision in component manufacturing. |

| Medical | The medical sector will continue to rely on CNC POR for creating custom prosthetics, dental implants, and medical devices. |

| Automotive | The automotive industry will increasingly utilize CNC POR for high-performance engines and custom designs. |

| Research and Development | Research and development activities across industries will spur the demand for CNC POR technology. |

CNC POR's potential applications are vast and diverse. It will remain crucial in aerospace, medical, automotive, and research and development sectors, contributing to precision and innovation.

Table 9: CNC POR Opportunities and Challenges

| Aspect | CNC POR Opportunities and Challenges |

|---|---|

| Opportunities | The demand for high-precision components continues to rise, presenting growth opportunities for CNC POR service providers. |

| Global Competition | Increased competition in the CNC POR sector is driving innovation and pushing companies to offer more efficient solutions. |

| Talent and Expertise | A skilled workforce with expertise in CNC POR technology will be essential to meet the growing demand. |

| Environmental Concerns | Sustainability and reduced environmental impact will shape future CNC POR developments. |

The future of CNC POR is brimming with opportunities. The increasing demand for high-precision components and global competition are driving innovation in the sector. However, addressing talent and expertise requirements and considering environmental concerns will be essential to sustain growth.

As CNC POR technology continues to evolve, it is poised to shape the future of precision manufacturing, unlocking new possibilities for various industries and creating exciting opportunities for businesses and professionals.

Every technology has its strengths and weaknesses. we'll take an in-depth look at the advantages and limitations of CNC POR, providing you with a well-rounded understanding of what to expect when considering CNC POR for your applications.

Table 10: Advantages of CNC POR

| Aspect | Advantages of CNC POR |

|---|---|

| Precision | CNC POR offers unparalleled rotational precision, ideal for intricate and complex components. |

| Efficiency | Simultaneous rotational control leads to increased efficiency, reducing machining time. |

| Customization | CNC POR enables high levels of customization, especially for parts with complex rotational features. |

| Versatility | Extremely versatile, CNC POR can handle a wide range of parts, making it suitable for various applications. |

| Quality Assurance | Feedback systems ensure continuous monitoring, maintaining precision and quality throughout the process. |

| Innovation Potential | Ongoing technological advancements in CNC POR equipment drive innovation and open doors to new applications. |

The advantages of CNC POR are clear, making it the technology of choice for precision manufacturing and customization. Its versatility and ongoing innovation further enhance its appeal.

Table 11: Limitations of CNC POR

| Aspect | Limitations of CNC POR |

|---|---|

| Initial Investment | The setup cost for CNC POR equipment can be relatively high, which might be a barrier for smaller businesses. |

| Complexity | Complex rotational features require a higher level of expertise, both in programming and machine operation. |

| Maintenance | CNC POR machines require regular maintenance to ensure optimal performance, which adds to operational costs. |

| Environmental Impact | Addressing environmental concerns is a challenge, as CNC POR may consume more energy compared to traditional CNC. |

While CNC POR excels in many aspects, it's important to acknowledge its limitations. The initial investment, complexity, maintenance requirements, and potential environmental impact are factors to consider when opting for CNC POR technology.

CNC POR technology is a game-changer in precision manufacturing, offering unmatched rotational precision and customization capabilities. While it comes with certain challenges, its advantages far outweigh its limitations, making it a valuable asset for industries that demand high-quality, customized components.

As you've journeyed through this comprehensive exploration of CNC POR, you now have a deep understanding of its fundamentals, applications, market trends, and advantages and limitations. Armed with this knowledge, you can make informed decisions and explore the full potential of CNC POR in your own projects and manufacturing endeavors.

Thriving Outsourcing PartnershipsOctober 12, 2023Manufacturers now view outsourcing not just as a supplier relationship, but as a partnership. Lei Sheng, product manager at Richconn, explains why outsourcing projects with reliable partners make sense.view

Thriving Outsourcing PartnershipsOctober 12, 2023Manufacturers now view outsourcing not just as a supplier relationship, but as a partnership. Lei Sheng, product manager at Richconn, explains why outsourcing projects with reliable partners make sense.view From Concept to Creation: A Comprehensive Guide to Jigs and Fixtures in Manufacturing ProcessesFebruary 27, 2024Here is a comprehensive guide to f jigs and fixtures in modern CNC manufacturing. Learn about their types, applications, and advantages.view

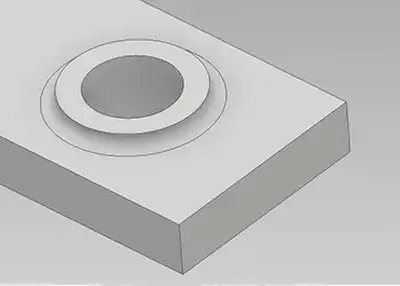

From Concept to Creation: A Comprehensive Guide to Jigs and Fixtures in Manufacturing ProcessesFebruary 27, 2024Here is a comprehensive guide to f jigs and fixtures in modern CNC manufacturing. Learn about their types, applications, and advantages.view What is a Machined Boss: A Comprehensive GuideNovember 8, 2023In the world of precision engineering, the term machined boss may not be a household name, but it is undoubtedly a crucial element that underpins countless industries. Whether you're a novice looking to expand your knowledge or a seasoned professional seeking in-depth insights, this article will serve as your comprehensive guide to understanding what a machined boss is, how it works, and why it matters.view

What is a Machined Boss: A Comprehensive GuideNovember 8, 2023In the world of precision engineering, the term machined boss may not be a household name, but it is undoubtedly a crucial element that underpins countless industries. Whether you're a novice looking to expand your knowledge or a seasoned professional seeking in-depth insights, this article will serve as your comprehensive guide to understanding what a machined boss is, how it works, and why it matters.view Tips On How to Find Low Cost CNC Milling ServicesOctober 24, 2023CNC milling services are not cheap. The more accurate the design you need, the more money you can expect to spend. Reliable machine shops employ professional operators who use state-of-the-art equipment to fulfill orders. As a result, you can't afford to ignore your budget in order to shorten lead times or gain a competitive edge.view

Tips On How to Find Low Cost CNC Milling ServicesOctober 24, 2023CNC milling services are not cheap. The more accurate the design you need, the more money you can expect to spend. Reliable machine shops employ professional operators who use state-of-the-art equipment to fulfill orders. As a result, you can't afford to ignore your budget in order to shorten lead times or gain a competitive edge.view Fillet Meaning: What Are Fillets in CNC Manufacturing?September 27, 2023Fillets are rounded corners that help increase strength and prevent rapid deformation at a part’s corners. Take a look at the fillet definition!view

Fillet Meaning: What Are Fillets in CNC Manufacturing?September 27, 2023Fillets are rounded corners that help increase strength and prevent rapid deformation at a part’s corners. Take a look at the fillet definition!view What Is Zinc Alloy? The Complete Basics to Get StartedOctober 8, 2023This article covers the information you need to watch out for in product design and part manufacturing when using zinc alloy. Take a deeper look into zinc alloy!view

What Is Zinc Alloy? The Complete Basics to Get StartedOctober 8, 2023This article covers the information you need to watch out for in product design and part manufacturing when using zinc alloy. Take a deeper look into zinc alloy!view