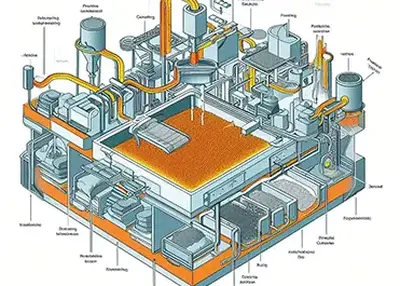

CNC lathes and steering centers are highly accurate and efficient automatic machine tools. The machine is equipped with a multi-station turret or power turret for a wide range of machining capabilities. It can handle linear cylinders, tilting cylinders, arcs and a variety of complex workpieces such as threads, grooves, worms, etc. The CNC lathe can be used for a wide range of applications. Interpolation of various compensation functions and good economic efficiency in the mass production of complex parts.

"CNC" is the abbreviation of computer numerical control. CNC machine tools automatically process the parts to be processed in accordance with the pre-programmed machining program. We will parts of the machining route, process parameters, tool trajectory, displacement, cutting parameters (spindle rotation, feed, return, etc.) and auxiliary functions (tool change, spindle positive, negative, cutting fluid on, off, etc.), according to the CNC machine tools specified instruction code and program format to write the machining program, and then the contents of the program will be recorded in the control media (such as perforated paper tape, magnetic tape, magnetic disks, magnetic bubble memory), and then entered into the numerical control of the CNC machine tool, thereby directing the machine tool to machine the part.

The entire process from analysis to analysis of the production control media is called NC program preparation. The difference between a CNC machine and an ordinary tool for machining parts is that a CNC machine automatically processes parts according to a program and requires a human to operate an ordinary machine. It is possible to change the program that controls the operation of the machine tool for the purpose of processing different parts. Therefore, CNC machines are particularly suitable for handling small batches and complex shapes that require high-precision parts.

Since CNC machines need to handle parts according to a program, after the programmer compiles the program, it is fed into the CNC machine to instruct the machine to work. The input of the program is through the control medium.

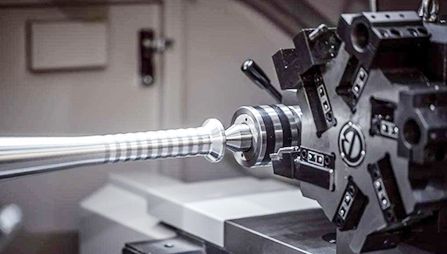

CNC lathe consists of CNC equipment, bed, spindle box, tool feed system, tailstock, hydraulic system, cooling system, lubrication system, chip conveyor and other components.CNC lathe is categorized into Vertical CNC lathe and Horizontal CNC lathe.

Vertical CNC lathe is used to turn disc parts with large rotating diameter.

Horizontal CNC lathe is used to turn parts with long shaft size or small disk.

Horizontal CNC lathes can be further classified into economical CNC lathes, normal CNC lathes and according to their functioning turning machining centers.

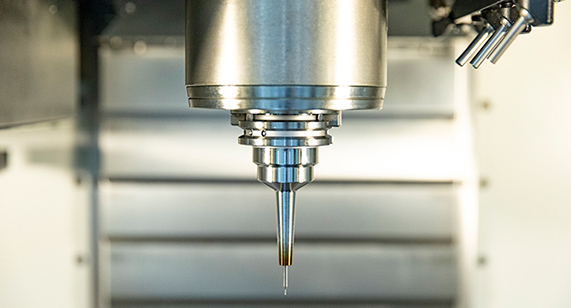

Ordinary CNC lathe: CNC lathe, specially designed for turning process, is equipped with universal numerical control system. The numerical control system has strong functions, and the degree of automation and machining accuracy is relatively high. It is suitable for turning processing of general rotating parts. This CNC lathe can control two axes at the same time, i.e. X-axis and Z-axis.

Rotary machining center: C-axis and power head are added to the general CNC lathe. More advanced machines also have tool magazines that can control X, Z and C axes. The connected control axes can be (x, z), (x, c) or (z, c). The machining capabilities of this CNC lathe are greatly enhanced by the addition of a power head for C-axis and milling. In addition to general rotation, it is possible to perform radial and axial milling, milling of curved surfaces and holes and diameters whose centerline is not in the center of rotation of the rotary drilled hole, etc.

Hydraulic chuck is an important part of the CNC turning process to clamp the workpiece. General rotary parts can be used ordinary hydraulic chuck; non-cylindrical clamping parts of the parts need special chuck; processing parts need spring chuck.

For parts with radial dimensions of the axial dimensions of a large ratio, it is necessary to use the real-time center mounted on the hydraulic tailstock to support the tail end of the part to ensure that part of the correct handling. The tailstock has an ordinary hydraulic tailstock and a programmable hydraulic tailstock.

CNC lathes can be equipped with two tool holders:

Special tool holders are developed by the lathe manufacturer itself and the tool holders used are specialized. The advantage of this tool holder is its lower manufacturing cost, but it lacks versatility.

Universal tool holders are produced according to certain common standards (e.g. VDI, Association of German Engineers), while CNC lathe manufacturers can select and configure them according to the functional requirements of the CNC lathe.

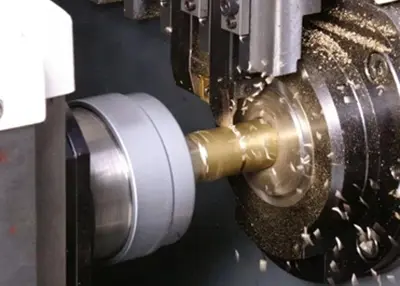

After installing the milling power head on the CNC lathe tool holder, the processing power of the CNC lathe can be greatly expanded. For example, use the milling power head to axially drill holes and mill axial slots.

When turning parts on CNC lathe or rotating machining centers, according to the structure of the tool holder of the lathe and the number of tools that can be installed, should be reasonably and scientifically arranged on the tool holder. Interference with machine tools, tools and workpieces and tools.

Compared with ordinary machine tools, CNC machine tools have high machining accuracy and stable quality; and can perform multi-coordinate link to have a complex shape of the processing parts; when the processing of parts change, only need to change the CNC program, greatly saving the production preparation time; at the same time, CNC machine tools themselves have high precision and rigidity, you can choose the amount of favorable machining, high productivity; and for the operator, CNC machine tools With a high degree of automation, greatly reducing the labor force; but because of the professionalism of the program control system, it is the operation and maintenance personnel quality requirements are relatively high. the maintenance of CNC machine tools than ordinary machine tools are more professional, meticulous. Maintenance personnel must not only understand the machinery, processing technology and hydraulics, but also has the knowledge of electronic computers, automatic control, drive and measurement technology. Understand and master the CNC lathe, and timely maintenance work.

Optimize the processing and production environment. The use of CNC lathe specific environment will affect the normal operation of the machine tool, so in the installation and use of the machine tool, it should try to meet the specified installation conditions to meet the environmental requirements of machine tool production. When economic conditions permit, it is best to isolate the CNC lathe from the general machining equipment so that the machine can be easily maintained and repaired. At the same time, the plant is frequently cleaned and the electrical cabinets, circuit boards, etc. are cleaned and inspected.

Train specialized tool machine maintenance personnel. The personnel should be familiar with the characteristics of the machine tool, CNC system, strong electrical equipment, hydraulic, pneumatic pressure and other operating conditions, machining conditions, etc., and can according to the requirements of the machine correctly use the CNC lathe tools and system manuals.

For machine tools using CMOS components, when a low voltage alarm occurs, the battery must be replaced in a timely manner, and the control system must be energized, otherwise the stored parameters will be lost and the CNC system will not work properly.

As well as long-term idle CNC machine tools. When not in use, the CNC system should always be stimulated and run under no-load conditions. In humid areas or rainy seasons, it should be electrical every day, and the electrical components themselves should be used to drive moisture out of the CNC cabinet to ensure the stability of the electronic components.

CNC lathes are indispensable tools in modern manufacturing, they are characterized by high precision and efficiency and can be automated to process a wide range of complex parts. At the heart of these machines is CNC technology, and they follow pre-written machining programs that ensure consistent and predictable machining times for every workpiece.

Richconn is a rapid prototyping companies that was founded in 2008, and they offer not only CNC machining services, but also sheet metal services and plating services to provide high-quality, customized solutions for their customers. No matter what type of fabrication service you need, Richconn can fulfill your needs. Their expertise and experience make them a reliable partner for your precision manufacturing needs. If you have any manufacturing needs or questions, why not contact Richconn and they will be happy to support you. Whether it's CNC machining, sheet metal fabrication, or plating, Richconn has the ability to provide you with exceptional service.

What is CNC Turning: Process, Operations, AdvantagesApril 11, 2024Here is a range of topics about CNC turning, including process, operations and advantages. Then, decide whether it is the best operation for your project.view

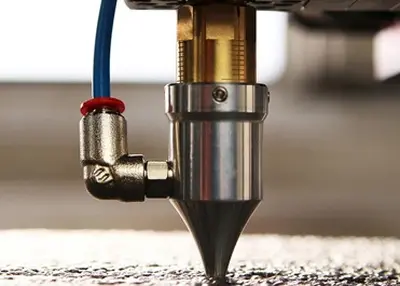

What is CNC Turning: Process, Operations, AdvantagesApril 11, 2024Here is a range of topics about CNC turning, including process, operations and advantages. Then, decide whether it is the best operation for your project.view What Is Laser Engraving And How Does Laser Engraving Work?March 20, 2024Laser engraving is one of the laser processing technologies. Before using the technology in your project, read this article to get all the information you need to know.view

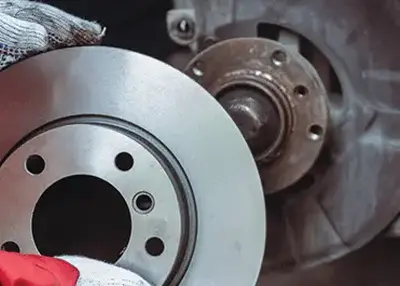

What Is Laser Engraving And How Does Laser Engraving Work?March 20, 2024Laser engraving is one of the laser processing technologies. Before using the technology in your project, read this article to get all the information you need to know.view What Are Machined Rotors?November 8, 2023Welcome to the world of precision engineering, where the subtle details can make a world of difference. In the realm of CNC machining and automotive components, 'Machined Rotors' emerge as a pivotal player, quietly ensuring your safety and vehicle performance.view

What Are Machined Rotors?November 8, 2023Welcome to the world of precision engineering, where the subtle details can make a world of difference. In the realm of CNC machining and automotive components, 'Machined Rotors' emerge as a pivotal player, quietly ensuring your safety and vehicle performance.view The Working Principle of CNC Cutting Aluminum SheetsFebruary 29, 2024The Intricacies of CNC Cutting Aluminum SheetsIn the intricate world of manufacturing and fabrication, CNC cutting aluminum sheets has become a cornerstone practice, heralding a new era of precision a...view

The Working Principle of CNC Cutting Aluminum SheetsFebruary 29, 2024The Intricacies of CNC Cutting Aluminum SheetsIn the intricate world of manufacturing and fabrication, CNC cutting aluminum sheets has become a cornerstone practice, heralding a new era of precision a...view What is the Powder Bed Fusion Process?November 28, 2023Powder bed fusion (PBF) is a type of additive manufacturing, or 3D printing, that uses a heat source, such as a laser or an electron beam, to melt and fuse material powder together to create solid parts.view

What is the Powder Bed Fusion Process?November 28, 2023Powder bed fusion (PBF) is a type of additive manufacturing, or 3D printing, that uses a heat source, such as a laser or an electron beam, to melt and fuse material powder together to create solid parts.view Top 6 Types of Rivets and Their Common UsesAugust 11, 2023Rivets hold a unique position in the history of engineering and construction. These seemingly small fasteners have played a critical role in joining materials together. Based on their properties and d...view

Top 6 Types of Rivets and Their Common UsesAugust 11, 2023Rivets hold a unique position in the history of engineering and construction. These seemingly small fasteners have played a critical role in joining materials together. Based on their properties and d...view

EN

EN

ru

ru