Are you designing medical parts? Just as there are countless medical procedures, there is now a seemingly endless abundance of polymer types. Which ones are best suited for medical applications? Good question. This design tip is meant to provide guidance, but it's important to start with the following caveat: The term "medical grade" is ambiguous at best.

Medical device manufacturers need to know and comply with a whole host of standards, but for the purposes of this discussion, ISO 10993 plays the lead role. It comprises nearly two dozen parts, four of which relate specifically to material selection. ISO 10993-13 for polymers may be the most relevant.

Unfortunately, there is no catalog or book listing which polymers meet which standards or which polymers are biocompatible at all. Complicating matters further is the fact that there are a variety of granules, pellets, powders and loose forms such as rods and plates to choose from, each from different manufacturers, some of which meet the requirements for medical devices and some of which do not. While one manufacturer offers medical-grade ABS, another makes ABS suitable for LEGO and power tool housings.

In general, medical device designers and manufacturers should look for polymers that are corrosion and chemical resistant and can withstand high temperatures. They should be non-absorbent, inert and able to withstand repeated autoclaving cycles. Of course, they should not react with body fluids and human tissue, as well as cause irritation or skin lesions. Have we touched on strength and durability yet? All of this may sound very challenging, but the good news is that a good handful of polymers meet at least most of these criteria.

An optically transparent polymer is often needed for medical procedures, and polycarbonate is the material of choice here. It meets all the usual requirements for toughness, dimensional stability, heat and chemical resistance, and sterilizability. It is not found in the human body, but PC is commonly used when it is necessary to view blood, drugs and other fluids flowing through a device. Many of Richconn's medical customers 3D print their designs from PC-like materials such as Acura 5530 and PerFORM, then move to machined or injection-molded polycarbonate as production needs increase.

Speaking of orthopedic implants, here's another important polymer to keep an eye on: ultra-high molecular weight polyethylene. If you've received a knee or hip replacement, chances are you have this material in you. UHMW-PE is an extremely dense, low-friction member of the polyethylene family. If you're looking for machined medical components (or wear-resistant machine parts), UHMW-PE has excellent impact and abrasion resistance and is also superbly biocompatible. And for somewhat less demanding applications, "regular" polyethylene (PE) and high-density polyethylene (HDPE) are good all-around polymers for a wide range of medical applications, especially for disposables and the personal protective equipment that has become so prevalent in recent years.

Like PEEK, polyetherimide is almost a superpolymer. Known by the trade name Ultem, PEI is a stiff, semi-transparent and heat-resistant (356 °F or 180 °C) polymer with a yellowish color and high tensile strength. Because it also has excellent dielectric properties and high flame resistance, it is widely used in electronic components, whether in medical or other fields. We machine and injection mold PEI into various shapes that can be used as handles for surgical instruments, housings for medical devices, insulators and electrical connectors, among others. Finally, PEI can be easily sterilized by autoclaving and gamma irradiation.

Another amber polymer is PSU, short for polysulfone. PSU is known for its toughness and rigidity at high temperatures. It is less strong than PEI, but more impact resistant. It can be machined or molded into filter housings, catheter connectors, surgical instrument trays and sizing devices for heart valve replacement. Polysulfone is considered one of the few polymers that can withstand more than 1000 cycles of steam sterilization (as can PEEK and PSU's even more impact- and heat-resistant cousin, polyphenylsulfone or PPSU).

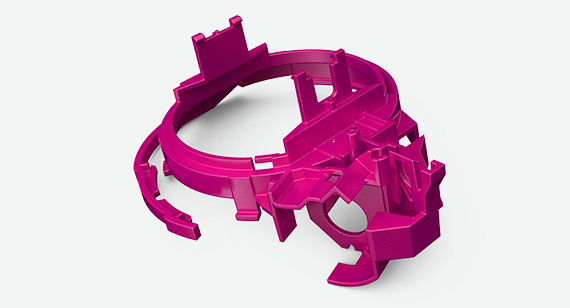

This medical component from IDEXX Laboratories, Inc. is part of a device veterinarians use to test blood and urine.

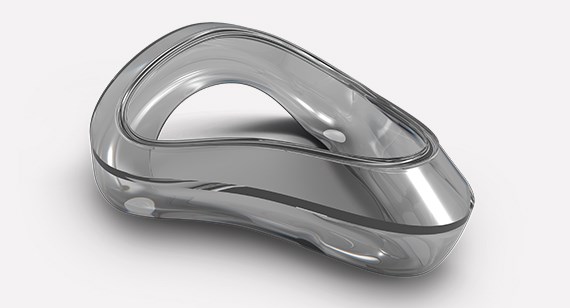

Medical grade injection molded silicone part.

Polyetheretherketone is a good place to start. PEEK has long been considered an "engineering" thermoplastic and is widely used in the medical industry. Orthopedic surgeons use it for trauma fixations, spinal implants and joint replacements, and dentists use it for crowns and bridges. Both lightweight and strong, PEEK is radiopaque (meaning it appears on X-rays) and retains its strength and dimensional stability even at high temperatures. And because PEEK is often placed in the human body for extended periods of time, it goes without saying that it is biocompatible and sterilizable. Richconn routinely performs CNC machining and plastic injection molding of PEEK into mechanical components such as gears, bearing surfaces and manifolds, as well as a variety of medical parts.

The stuff of weatherproof adhesives and cooking utensils is also great for many medical components. Silicone comes in various degrees of hardness, from soft and stretchy like a rubber band to hard like a tire tread. It can withstand temperatures from sub-zero to oven-hot (-55 °C to 210 °C), is hydrophobic (water repellent), solvent and acid resistant, and has good vapor permeability, making it a popular material for prosthetics. Richconn 3d printing service a variety of medical components, including gaskets, seals and surgical models, and injection molds all kinds of prototype and production parts for end users from liquid silicone (LSR). You can even use silicone as a 3D printing material. This is a good option for Prototype Manufacturing complex parts or transitioning to injection molding for larger production quantities. In addition, there is also an optical silicone, OSLR, that has better refractive and light transmission properties compared to PC or PMMA (acrylic) alternatives. It is therefore popular for lenses and lighting applications, as well as wherever a clear, non-yellowing, heat- and chemical-resistant biocompatible polymer is needed.

An operator removes a silicone part from the LSR press. Due to the elasticity of silicone parts, manual removal is required.

These six polymers suitable for medical purposes are just the beginning. It would be churlish not to mention PTFE, better known as Teflon, a particularly lubricious polymer used in catheters, stents and heart-lung machines. Impact and chemical-resistant acrylonitrile butadiene styrene (ABS) is sometimes used to replace metal parts in medical devices, as is acetal (you may know it as Delrin), while polyvinyl chloride (PVC) is considered a flexible version of polycarbonate in certain applications. Polyethylene terephthalate (PET) is resistant to attack by microorganisms, making it just as suitable for beverage containers as for wearable sensors. And polypropylene (PP), while considered a standard plastic, is commonly used for sample and drug containers and disposable syringes (and is also a good choice for parts that would benefit from an active hinge).

As with any manufacturing application, choosing the best material for a medical device depends on the physical, chemical and electrical requirements, not to mention the environment of use. Feasibility and all the associated design rules must also be considered. And at the end of the design and prototyping process, the ordeal of regulatory approval awaits. It can be very confusing to navigate this environment. That's why we recommend you upload a file, get a quote, and call us to discuss your options. We have helped countless others in similar situations.

6 Considerations When Designing Parts For CNCOctober 11, 2023The fact is that when manufacturing parts through on-demand CNC machining, various aspects must be weighed against each other. After all, you wouldn't expect to buy a Bentley for the price of a Mini, but they both basically perform the same function and get us from point A to point B.view

6 Considerations When Designing Parts For CNCOctober 11, 2023The fact is that when manufacturing parts through on-demand CNC machining, various aspects must be weighed against each other. After all, you wouldn't expect to buy a Bentley for the price of a Mini, but they both basically perform the same function and get us from point A to point B.view A Basic Introduction to CNC LathesJune 11, 2024If you're eager to delve into the captivating realm of CNC lathes, this article is your gateway. Whether you're interested in their specific functionalities, wide-ranging applications, or significant roles in the manufacturing industry, this is the perfect read to quench your curiosity.view

A Basic Introduction to CNC LathesJune 11, 2024If you're eager to delve into the captivating realm of CNC lathes, this article is your gateway. Whether you're interested in their specific functionalities, wide-ranging applications, or significant roles in the manufacturing industry, this is the perfect read to quench your curiosity.view What Is A Coordinate Measuring Machine Used For?July 16, 2024A coordinate measuring machine is often used to qualify rapid prototypes and production parts that have complex geometries with tight tolerances. Learn more about it to ensure every part you make meets and exceeds your expectations.view

What Is A Coordinate Measuring Machine Used For?July 16, 2024A coordinate measuring machine is often used to qualify rapid prototypes and production parts that have complex geometries with tight tolerances. Learn more about it to ensure every part you make meets and exceeds your expectations.view Deburring Guide: Everything You Need to Know about DeburringNovember 2, 2023This deburring guide helps you get the best understanding of the deburring process. Learn more to eliminate the part burrs.view

Deburring Guide: Everything You Need to Know about DeburringNovember 2, 2023This deburring guide helps you get the best understanding of the deburring process. Learn more to eliminate the part burrs.view Precision Engineered CNC Turning PartsSeptember 22, 2023CNC turned parts are a type of mechanical part that is manufactured through numerical control (Computer Numerical Control, CNC) technology.view

Precision Engineered CNC Turning PartsSeptember 22, 2023CNC turned parts are a type of mechanical part that is manufactured through numerical control (Computer Numerical Control, CNC) technology.view Precision at Work: CNC Advancements in the Electronic SectorJuly 2, 2024Let’s discover the great impact of CNC technology in the electronic sector. Explore how precision, efficiency, and innovation converge to reshape electronic manufacturing processes, driving advancements and elevating industry standards to new heights.view

Precision at Work: CNC Advancements in the Electronic SectorJuly 2, 2024Let’s discover the great impact of CNC technology in the electronic sector. Explore how precision, efficiency, and innovation converge to reshape electronic manufacturing processes, driving advancements and elevating industry standards to new heights.view

EN

EN

ru

ru