Are you ready to delve into the fascinating world of machined bushes? If you're curious about what machined bushes are, how they are made, where they are used, and how to choose the right ones for your specific needs, you've come to the right place. I'm here to guide you through this journey of discovery.

Let's start at the beginning. Machined bushes, also known as plain bearings or sleeve bearings, are precision-engineered components designed to reduce friction between moving parts. They play a critical role in various industries, offering support, stability, and durability where needed.

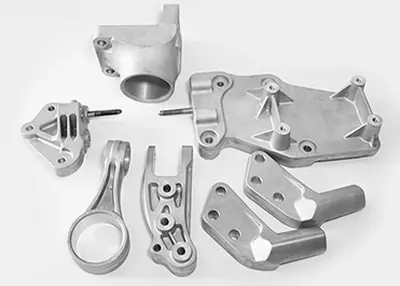

Machined bushes are typically cylindrical in shape, with a smooth inner and outer surface. These versatile components can be made from various materials such as bronze, aluminum, steel, and more. The choice of material depends on the specific application.

Machined bushes have a long history and have evolved over time to meet the ever-increasing demands of modern industry. Today, they are found in a wide range of applications, from industrial machinery to consumer products. These unassuming components often work silently behind the scenes, ensuring the smooth operation of countless systems.

The history of machined bushes dates back to ancient civilizations, where simple sleeve bearings were used to reduce friction in manual labor tasks. However, it was during the industrial revolution that the need for more advanced bushing solutions became apparent. As machinery grew more complex and demanding, traditional solutions were no longer sufficient.

In the mid-20th century, advancements in machining technology, particularly the introduction of CNC machining, revolutionized the production of machined bushes. This allowed for unprecedented precision and consistency in manufacturing, making machined bushes an integral part of modern engineering.

Today, machined bushes are highly specialized components, with manufacturers like Richconn leading the way in precision engineering. These components are tailored to meet the exacting requirements of diverse industries, from aerospace to automotive.

Machined bushes play a crucial role in reducing friction between moving parts. They are designed to fit snugly within a housing or on a shaft, providing a smooth and low-friction surface for other components to interact with. This not only reduces wear and tear but also enhances the efficiency and longevity of the machinery.

One of the remarkable aspects of machined bushes is their ability to function without the need for a constant supply of lubrication. This is particularly advantageous in applications where maintenance access is limited or in situations where cleanliness is critical, such as in the food and pharmaceutical industries.

Machined bushes are found in various configurations, including plain cylindrical bushes, flanged bushes, and thrust washers. These configurations cater to different load-bearing requirements and operating conditions.

Machined bushes owe much of their performance to the materials from which they are crafted and the precision manufacturing processes that shape them. Understanding these critical aspects will help you appreciate the role machined bushes play in modern machinery.

The choice of material for machined bushes is a pivotal decision that directly impacts their performance and longevity. Different materials offer distinct advantages and are suitable for specific applications. Here are some common materials used:

| Material | Advantages | Applications |

|---|---|---|

| Bronze | Excellent wear resistance, corrosion resistance, and load capacity. | Industrial machinery, marine equipment. |

| Aluminum | Lightweight, corrosion-resistant, and suitable for low-load applications. | Aerospace, automotive suspension systems. |

| Steel | High strength, durability, and heat resistance. | Automotive engines, heavy machinery. |

| PTFE (Polytetrafluoroethylene) | Self-lubricating, chemically inert, and low friction. | Food processing, medical equipment. |

The choice of material should align with your application's specific requirements. For instance, if you're working in a harsh environment, you might opt for bronze machined bushes for their corrosion resistance. If weight is a concern, aluminum could be a suitable choice.

Machined bushes are known for their precision, and this level of accuracy is achieved through advanced manufacturing techniques. CNC (Computer Numerical Control) machining is a standout technology in the production of machined bushes.

CNC machining allows for high levels of precision and repeatability. It involves computer-controlled machining tools that follow a programmed set of movements, ensuring that each machined bush meets the exact specifications required for the application.

The process typically begins with a solid metal or plastic blank, which is precisely shaped using cutting tools and drills. This level of precision ensures that the final product adheres to the required inner diameter, outer diameter, and length.

Machined bushes manufactured using CNC processes offer several advantages, such as consistency in dimensions, improved surface finishes, and the capability to create intricate designs. These advantages make machined bushes suitable for applications where tight tolerances and reliability are paramount.

Richconn, a leading precision machine shop in China, leverages the power of CNC machining to produce high-quality machined bushes. With state-of-the-art equipment and a team of experienced professionals, Richconn ensures that each machined bush meets the most stringent quality standards.

Understanding the specifications and characteristics of machined bushes is vital when selecting the right components for your application. These parameters determine how effectively machined bushes will perform in various scenarios. Let's take a closer look at these critical aspects.

Machined bushes come in a variety of specifications, and choosing the right ones involves considering the following factors:

Inner Diameter (ID): The inner diameter of a machined bush determines the size of the shaft or pin it will fit. It's essential to select a bush with an ID that matches your equipment's requirements.

Outer Diameter (OD): The outer diameter corresponds to the size of the housing or bore in which the bush will be placed. The OD must align with the available space in your machinery.

Length: The length of the machined bush impacts its load-bearing capacity and stability. Longer bushes can distribute heavier loads, but it's crucial to match the length to the application's needs.

Flange: Some machined bushes come with a flange, which provides added stability and helps in alignment. Flanged bushes are ideal for applications where precise positioning is required.

Machined bushes possess various characteristics that make them a versatile choice in many applications. Here are some key characteristics:

Load-Bearing Capacity: Machined bushes can handle substantial loads, making them suitable for a wide range of machinery and equipment. The material choice influences their load-bearing capacity.

Wear Resistance: The materials used in machined bushes, especially bronze and steel, offer excellent wear resistance. This ensures prolonged service life even in high-friction environments.

Friction Reduction: One of the primary purposes of machined bushes is to reduce friction between moving parts. This results in smoother operation and less energy consumption.

Self-Lubrication: Some machined bushes are self-lubricating, thanks to materials like PTFE. This property reduces the need for constant maintenance and lubrication.

Corrosion Resistance: Certain materials, such as bronze and aluminum, provide good resistance to corrosion, making them suitable for outdoor or marine applications.

Selecting machined bushes with the right combination of specifications and characteristics is crucial to ensuring optimal performance and longevity in your equipment.

In cases where standard off-the-shelf machined bushes do not meet your specific requirements, custom solutions may be the answer. Custom machined bushes are tailored to your unique needs, considering factors such as material, dimensions, and special features.

Richconn, as a leading CNC machining service provider in China, offers custom machined bushes to cater to the precise needs of various industries. With a commitment to quality and precision, Richconn ensures that your custom machined bushes meet the highest standards, delivering reliable performance in your applications.

Machined bushes are integral components in a multitude of industries, contributing to the smooth operation of various machinery and equipment. Their adaptability and versatility make them indispensable in applications where reliability is paramount. Let's explore some of the most common industries and how machined bushes play a vital role in each.

In the field of mechanical engineering, machined bushes find widespread use. They are employed in various components, such as bearings, bushings, and thrust washers, to reduce friction and ensure the smooth movement of parts. Here are some specific applications:

Bearings: Machined bushes act as bearings in rotating equipment, such as conveyor rollers, which require low friction and durability.

Bushings: In machines like lathes and milling machines, machined bushes are used to support and guide moving parts.

Thrust Washers: Machined bushes are crucial in applications with axial loads, ensuring efficient and reliable thrust bearing.

The automotive sector heavily relies on machined bushes to enhance vehicle performance, safety, and longevity. Machined bushes can be found in various components, including:

Suspension Systems: In the automotive suspension system, machined bushes provide stability and comfort by reducing friction and absorbing vibrations.

Engines: They play a role in engine components like connecting rods and crankshafts, ensuring smooth movement and reduced wear.

Transmissions: Machined bushes are used in gearboxes, enhancing shifting precision and reliability.

The agricultural industry benefits from machined bushes in various ways. Farm machinery and equipment utilize these components for applications such as:

Tractor Bushings: Machined bushes in tractor parts ensure smooth and efficient operation in the field.

Harvesting Equipment: They are essential in harvesting machines for reliability and longevity.

Irrigation Systems: Machined bushes help ensure the proper functioning of irrigation systems in agriculture.

The aerospace industry demands high precision and reliability, making machined bushes an excellent choice for various applications. They are used in:

Aircraft Landing Gear: Landing gear components require machined bushes to withstand high loads and provide smooth movement during takeoff and landing.

Control Surfaces: In aircraft control surfaces, machined bushes play a crucial role in ensuring precise and responsive movement.

Engines: They are used in aircraft engines to reduce friction and ensure efficient operation.

In the harsh marine environment, machined bushes excel due to their corrosion-resistant properties. They find applications in:

Propulsion Systems: In ship propulsion systems, machined bushes reduce friction and support moving parts.

Navigation Equipment: Precision navigation equipment on vessels relies on machined bushes for reliability.

Beyond industrial applications, machined bushes are also found in various consumer products, including household appliances, bicycles, and fitness equipment. In these applications, they ensure smooth operation and extended product life.

By contributing to these industries, machined bushes are integral components that keep machinery and equipment operating efficiently. Their adaptability to different environments and loads makes them a dependable choice in countless applications.

Selecting the appropriate machined bushes for your application involves a thoughtful process. It's essential to consider specific factors to ensure optimal performance and longevity. Here are the crucial steps to guide you in making the right choice.

Before embarking on your machined bush selection journey, it's crucial to have a clear understanding of your application's requirements. Take the following steps:

Identify the Load: Determine the expected load that the machined bush will need to bear. Different applications require different load-bearing capacities.

Environmental Considerations: Assess the environmental conditions, such as temperature, humidity, and exposure to chemicals, to choose a material that can withstand them.

Dimensions: Measure the available space within your equipment to ensure that the machined bush's inner and outer diameters align with your requirements.

Operating Speed: Consider the rotational or sliding speed at which the machined bush will operate. Some applications may require high-speed or low-speed capabilities.

The choice of material is a crucial decision, as it directly impacts the machined bush's performance and longevity. Refer to the table of materials discussed earlier in the article to select the most appropriate material based on your application's requirements.

If your application demands unique specifications that standard machined bushes cannot provide, consider custom machined bushes. Customization allows you to tailor the bush to meet your exact requirements. Discuss your specific needs with a reliable supplier like Richconn to explore this option.

Selecting the right supplier is a critical step in obtaining high-quality machined bushes. Here are key considerations when choosing a supplier:

Experience: Look for a supplier with a track record of producing high-quality machined bushes for various industries.

Quality Control: Inquire about the supplier's quality control processes to ensure consistent product quality.

Customization Capabilities: If you require custom machined bushes, choose a supplier with the ability to meet your unique specifications.

Reputation: Read customer reviews and testimonials to gauge the supplier's reputation and reliability.

Richconn, a renowned CNC machining service provider in China, offers a wealth of experience in producing machined bushes for diverse applications. We specialize in precision engineering and can provide customized solutions to meet your specific needs.

After selecting and installing machined bushes in your equipment, it's essential to establish a maintenance and lubrication schedule. Regular maintenance helps extend the service life of the machined bushes. Consult with your supplier or follow their recommendations for maintenance procedures and lubrication requirements.

By taking these steps, you can ensure that the machined bushes you select are well-suited to your application and will provide reliable performance over the long term.

In the ever-evolving world of engineering and machinery, staying informed about the latest market trends and developments related to machined bushes is crucial. This knowledge empowers you to make informed decisions, adapt to changing requirements, and remain competitive in your industry. Let's explore some of the current trends and insights in the machined bushes market.

The development of advanced materials for machined bushes is a significant trend. These materials aim to enhance the properties of machined bushes, such as increased wear resistance, improved corrosion resistance, and reduced friction. Engineers and manufacturers are continually exploring innovative materials to meet the evolving needs of various industries.

Sustainability is an increasingly important factor in manufacturing. This trend has led to the development of eco-friendly materials and lubrication options for machined bushes. Reduced friction not only improves efficiency but also contributes to energy savings and lower environmental impact.

Digitalization and Industry 4.0 are driving the integration of smart technologies into manufacturing processes. This includes advanced sensors and data analytics for predictive maintenance of machinery that employs machined bushes. These technologies help in identifying potential issues before they lead to costly breakdowns.

Global supply chain dynamics have a significant impact on the availability and pricing of materials used in machined bushes. Understanding these dynamics, such as the availability of raw materials and trade regulations, is vital for manufacturers and consumers alike.

The machined bushes market continues to grow, driven by increased demand across various industries. As machinery and equipment become more advanced and specialized, the need for precision-engineered components like machined bushes is on the rise.

The competitive landscape of machined bushes is evolving as new players enter the market. Competition often leads to innovation and improvements in product quality and cost-effectiveness. Staying informed about the competitive landscape can help you make informed choices when selecting a supplier.

Keeping an eye on these trends and insights can provide valuable information to guide your decision-making process when it comes to machined bushes. Whether you are an engineer, a manufacturer, or a business owner, staying informed about these developments can give you a competitive edge in your industry.

The machined bushes are integral components in a wide range of applications, and understanding their specifications, characteristics, and applications is crucial. By following the steps for selecting and purchasing the right machined bushes, you can ensure that your machinery and equipment operate smoothly and efficiently. Stay informed about market trends to adapt to changing industry needs and make the best choices for your specific requirements.

If you have any further questions or need additional information, please feel free to reach out. Your journey into the world of machined bushes is just beginning, and Richconn is here to support you every step of the way.

Different Types of Bearings: Their Distinctive Features and Diverse UsesMay 28, 2024Learn about the importance of mechanical bearings, different types, and how to choose the right one for your needs. Explore applications in various fields and factors to consider for smooth and precise motions.view

Different Types of Bearings: Their Distinctive Features and Diverse UsesMay 28, 2024Learn about the importance of mechanical bearings, different types, and how to choose the right one for your needs. Explore applications in various fields and factors to consider for smooth and precise motions.view Electrophoretic Surface Treatment Process Characteristics and Main CharacteristicsSeptember 16, 20221. Characteristics of electrophoresis surface treatment processElectrophoretic paint film has the advantages of full, uniform, flat and smooth coating. The hardness, adhesion, corrosion resistance, im...view

Electrophoretic Surface Treatment Process Characteristics and Main CharacteristicsSeptember 16, 20221. Characteristics of electrophoresis surface treatment processElectrophoretic paint film has the advantages of full, uniform, flat and smooth coating. The hardness, adhesion, corrosion resistance, im...view Application of 5-Axis Machining Center in High-Speed Blower Impeller ManufacturingMarch 24, 2023With the rapid development of technology, high-speed blowers have been widely used in various fields. In order to improve the performance and efficiency of the blowers, it is necessary to manufacture ...view

Application of 5-Axis Machining Center in High-Speed Blower Impeller ManufacturingMarch 24, 2023With the rapid development of technology, high-speed blowers have been widely used in various fields. In order to improve the performance and efficiency of the blowers, it is necessary to manufacture ...view The Application of CNC Machining in Mechanical Equipment - CNC PartsMay 13, 2024Discover the wide range of applications and future trends of CNC machined parts in mechanical equipment. From high precision to increased efficiency, this technology is pushing forward the industry. Explore the possibilities now!view

The Application of CNC Machining in Mechanical Equipment - CNC PartsMay 13, 2024Discover the wide range of applications and future trends of CNC machined parts in mechanical equipment. From high precision to increased efficiency, this technology is pushing forward the industry. Explore the possibilities now!view CNC Machining Technology and ProcessJuly 27, 2023CNC Machining TechnologyCNC machining technology mainly includes CNC machine tool machining technology and CNC machine tool programming technology. CNC machine tool machining technology directly compl...view

CNC Machining Technology and ProcessJuly 27, 2023CNC Machining TechnologyCNC machining technology mainly includes CNC machine tool machining technology and CNC machine tool programming technology. CNC machine tool machining technology directly compl...view Aluminum Alloy Anodic Oxidation Common ProblemsOctober 23, 2023Anodizing is one of the most common metal surface treatment operations performed on aluminum parts. It is an electrochemical process that involves immersing aluminum parts in a series of tanks to transform the aluminum surface into a durable and corrosion-resistant finish.view

Aluminum Alloy Anodic Oxidation Common ProblemsOctober 23, 2023Anodizing is one of the most common metal surface treatment operations performed on aluminum parts. It is an electrochemical process that involves immersing aluminum parts in a series of tanks to transform the aluminum surface into a durable and corrosion-resistant finish.view