Carbon steel is one of the most common and widely used materials in the world, thanks to its low cost, high strength, and versatility.

Carbon steel is an alloy of iron and carbon, with a carbon content ranging from 0.04% to 2.1%, depending on the grade. Carbon steel can be classified into four main types, based on the carbon content and the microstructure: low carbon steel, medium carbon steel, high carbon steel, and ultra-high carbon steel.

The carbon content of carbon steel affects its properties and performance, such as hardness, ductility, weldability, and corrosion resistance. Generally, the higher the carbon content, the harder and stronger the steel, but the lower the ductility and weldability. The microstructure of carbon steel also affects its properties and performance, such as toughness, fatigue resistance, and wear resistance. The microstructure of carbon steel can be changed by heat treatment, such as annealing, quenching, and tempering, to achieve the desired properties and performance.

Carbon steel has a wide range of applications, such as construction, engineering, manufacturing, transportation, energy, etc. Carbon steel can be used to make various products and components, such as beams, columns, pipes, wires, nails, screws, bolts, nuts, springs, gears, knives, blades, etc. Carbon steel can also be combined with other metals, such as chromium, nickel, manganese, molybdenum, etc., to form different types of alloys, such as stainless steel, tool steel, alloy steel, etc.

High carbon steel is a type of carbon steel that has a carbon content ranging from 0.6% to 2.1%, depending on the grade. High carbon steel is also known as carbon tool steel or carbon alloy steel. High carbon steel has a high hardness and strength, but a low ductility and weldability. High carbon steel can be heat treated to achieve different properties and performance, such as tempering, hardening, and annealing.

The table below shows the typical properties of high carbon steel. The properties are measured by the Rockwell C hardness scale, the tensile strength, the yield strength, and the elongation.

| Grade | Carbon Content (%) | Hardness (HRC) | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) |

|---|---|---|---|---|---|

| 1060 | 0.6 | 20-22 | 635 | 540 | 10 |

| 1075 | 0.75 | 25-27 | 725 | 620 | 8 |

| 1095 | 0.95 | 30-32 | 830 | 725 | 6 |

| W1 | 1.1 | 35-37 | 930 | 830 | 4 |

| W2 | 1.5 | 40-42 | 1030 | 930 | 3 |

| D2 | 1.5 | 55-60 | 1580 | 1440 | 2 |

As can be seen from the table, the higher the carbon content, the higher the hardness and strength, but the lower the ductility and weldability. High carbon steel can withstand high stress and pressure, but it is more prone to cracking and breaking. High carbon steel also has a low corrosion resistance, which means it can rust and corrode easily.

High carbon steel has a wide range of uses, such as:

High carbon steel is used to make various cutting tools, such as knives, blades, scissors, razors, saws, chisels, etc. High carbon steel has a high hardness and sharpness, which can cut through various materials, such as wood, metal, plastic, etc. High carbon steel also has a high wear resistance, which means it can maintain its edge and shape for a long time.

High carbon steel is used to make various springs, such as coil springs, leaf springs, torsion springs, etc. High carbon steel has a high elasticity and resilience, which means it can store and release energy when compressed or stretched. High carbon steel also has a high fatigue resistance, which means it can withstand repeated stress and strain without breaking.

High carbon steel is used to make various wires, such as piano wires, guitar strings, fishing lines, etc. High carbon steel has a high tensile strength and stiffness, which means it can support high loads and vibrations without breaking or sagging. High carbon steel also has a high ductility, which means it can be drawn into thin and long wires without losing its strength.

High carbon steel has a high hardness and strength, which makes it suitable for applications that require high performance and durability, such as cutting tools, springs, and wires.

High carbon steel has a high wear and fatigue resistance, which makes it suitable for applications that require high endurance and reliability, such as cutting tools, springs, and wires.

High carbon steel has a low cost, which makes it suitable for applications that require high quantity and quality, such as cutting tools, springs, and wires.

High carbon steel has a low ductility and weldability, which makes it unsuitable for applications that require high flexibility and formability, such as bending, shaping, and joining.

High carbon steel has a low corrosion resistance, which makes it unsuitable for applications that require high resistance to rust and corrosion, such as outdoor and marine environments.

High carbon steel has a high maintenance, which makes it unsuitable for applications that require low maintenance and care, such as cleaning, polishing, and coating.

Low carbon steel is a type of carbon steel that has a carbon content ranging from 0.04% to 0.3%, depending on the grade. Low carbon steel is also known as mild steel or plain carbon steel. Low carbon steel has a low hardness and strength, but a high ductility and weldability. Low carbon steel can be heat treated to achieve different properties and performance, such as normalizing, annealing, and carburizing.

The table below shows the typical properties of low carbon steel. The properties are measured by the Rockwell B hardness scale, the tensile strength, the yield strength, and the elongation.

| Grade | Carbon Content (%) | Hardness (HRB) | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) |

|---|---|---|---|---|---|

| 1008 | 0.08 | 55 | 340 | 285 | 20 |

| 1018 | 0.18 | 71 | 440 | 370 | 15 |

| 1020 | 0.2 | 75 | 460 | 390 | 15 |

| 1030 | 0.3 | 80 | 510 | 435 | 15 |

As can be seen from the table, the lower the carbon content, the lower the hardness and strength, but the higher the ductility and weldability. Low carbon steel can deform and bend easily, but it is more prone to denting and scratching. Low carbon steel also has a low corrosion resistance, which means it can rust and corrode easily.

Low carbon steel has a wide range of uses, such as:

Low carbon steel is used to make various structural and architectural materials, such as beams, columns, bars, rods, plates, sheets, etc. Low carbon steel has a high ductility and weldability, which makes it suitable for applications that require high flexibility and formability, such as bending, shaping, and joining. Low carbon steel also has a low cost, which makes it suitable for applications that require high quantity and quality, such as construction and architecture.

Low carbon steel is used to make various automotive and transportation components, such as frames, chassis, bodies, panels, doors, bumpers, etc. Low carbon steel has a high ductility and weldability, which makes it suitable for applications that require high flexibility and formability, such as bending, shaping, and joining. Low carbon steel also has a low weight, which makes it suitable for applications that require high fuel efficiency and performance, such as automotive and transportation.

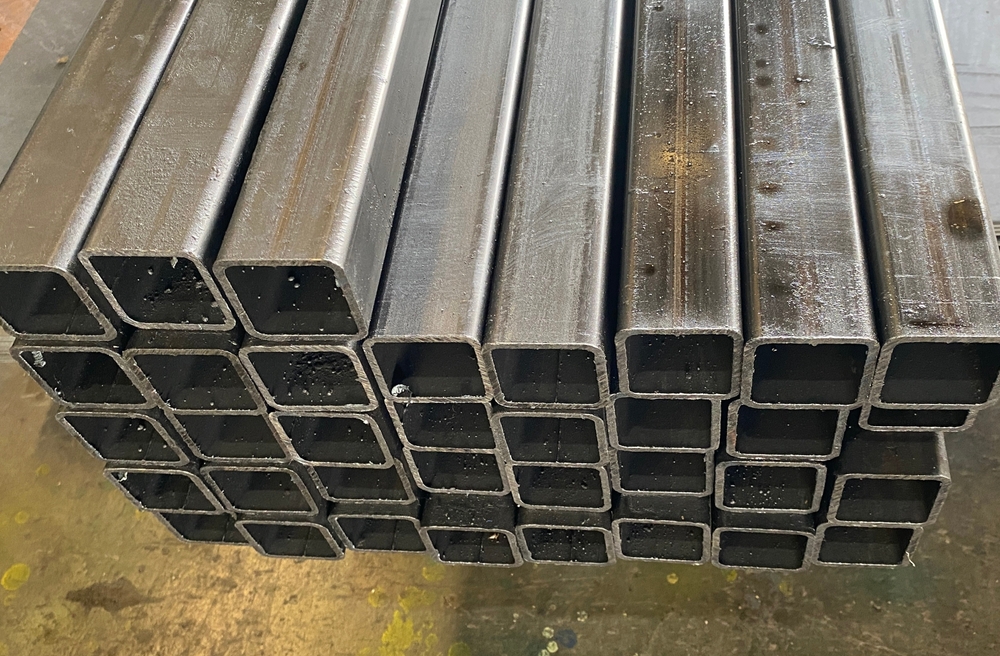

Low carbon steel is used to make various pipes and tubes, such as water pipes, gas pipes, oil pipes, steam pipes, etc. Low carbon steel has a high ductility and weldability, which makes it suitable for applications that require high flexibility and formability, such as bending, shaping, and joining. Low carbon steel also has a low cost, which makes it suitable for applications that require high quantity and quality, such as pipes and tubes.

Low carbon steel has a high ductility and weldability, which makes it suitable for applications that require high flexibility and formability, such as bending, shaping, and joining.

Low carbon steel has a low cost and weight, which makes it suitable for applications that require high quantity and quality, such as structural and architectural materials, automotive and transportation components, pipes and tubes.

Low carbon steel has a high availability and demand, which makes it suitable for applications that require high accessibility and convenience, such as structural and architectural materials, automotive and transportation components, pipes and tubes.

Low carbon steel has a low hardness and strength, which makes it unsuitable for applications that require high performance and durability, such as cutting tools, springs, and wires.

Low carbon steel has a low corrosion resistance, which makes it unsuitable for applications that require high resistance to rust and corrosion, such as outdoor and marine environments.

Low carbon steel has a high maintenance, which makes it unsuitable for applications that require low maintenance and care, such as cleaning, polishing, and coating.

Carbon steel is one of the most common and widely used metals in the world, but it is not the only one. There are many other types of metals, such as stainless steel, aluminum, copper, etc., that have different properties and applications.

The main difference between carbon steel and other metals is the composition. Carbon steel is an alloy of iron and carbon, with a carbon content ranging from 0.04% to 2.1%, depending on the grade. Other metals have different compositions, depending on the type and the grade. For example, stainless steel is an alloy of iron, chromium, nickel, and other elements, with a chromium content of at least 10.5%. Aluminum is a pure metal, with a small amount of other elements, such as silicon, magnesium, copper, etc. Copper is also a pure metal, with a small amount of other elements, such as zinc, tin, nickel, etc.

The difference in the composition affects the properties and performance of the metals. For example, the chromium content of stainless steel forms a thin and protective layer of chromium oxide on the surface of the steel, which prevents the steel from reacting with oxygen, water, and other substances, and thus prevents corrosion, rust, and stains. The silicon and magnesium content of aluminum improves the strength and hardness of the metal, while the copper content improves the electrical and thermal conductivity. The zinc and tin content of copper improves the corrosion resistance and the ductility of the metal, while the nickel content improves the strength and the hardness.

The main similarity between carbon steel and other metals is the corrosion resistance. All metals have some degree of corrosion resistance, which means they can resist the reaction with oxygen, water, and other substances, and thus prevent corrosion, rust, and stains. However, the degree of corrosion resistance varies depending on the type and the grade of the metal. Generally, the higher the chromium and nickel content, the higher the corrosion resistance, while the higher the carbon and iron content, the lower the corrosion resistance.

For example, stainless steel has a high corrosion resistance, because it has a high chromium and nickel content, which forms a thin and protective layer of chromium oxide on the surface of the steel, which prevents the steel from reacting with oxygen, water, and other substances, and thus prevents corrosion, rust, and stains. Stainless steel is also resistant to various organic and inorganic acids, alkalis, and salts, which can prevent pitting, crevice, and stress corrosion cracking. Stainless steel is suitable for applications that require high resistance to rust and corrosion, such as outdoor and marine environments, food and beverage, medical and pharmaceutical, chemical and petrochemical, etc.

Carbon steel has a low corrosion resistance, because it has a high carbon and iron content, which makes it more prone to react with oxygen, water, and other substances, and thus causes corrosion, rust, and stains. Carbon steel is also susceptible to various organic and inorganic acids, alkalis, and salts, which can cause pitting, crevice, and stress corrosion cracking. Carbon steel is not suitable for applications that require high resistance to rust and corrosion, such as outdoor and marine environments, food and beverage, medical and pharmaceutical, chemical and petrochemical, etc.

Aluminum has a moderate corrosion resistance, because it has a low carbon and iron content, but a high silicon and magnesium content, which forms a thin and protective layer of aluminum oxide on the surface of the metal, which prevents the metal from reacting with oxygen, water, and other substances, and thus prevents corrosion, rust, and stains. Aluminum is also resistant to some organic and inorganic acids, alkalis, and salts, but not to others, such as sulfuric acid, hydrochloric acid, sodium chloride, etc. Aluminum is suitable for applications that require moderate resistance to rust and corrosion, such as construction and architecture, automotive and transportation, energy and power, etc.

Copper has a low corrosion resistance, because it has a low carbon and iron content, but a high copper content, which makes it more prone to react with oxygen, water, and other substances, and thus causes corrosion, rust, and stains. Copper is also susceptible to various organic and inorganic acids, alkalis, and salts, which can cause pitting, crevice, and stress corrosion cracking. Copper is not suitable for applications that require high resistance to rust and corrosion, such as outdoor and marine environments, food and beverage, medical and pharmaceutical, chemical and petrochemical, etc.

The main difference between carbon steel and other metals in terms of strength is the carbon content. The carbon content of carbon steel affects its hardness and strength, which are the resistance of the metal to indentation and deformation. Generally, the higher the carbon content, the higher the hardness and strength, while the lower the carbon content, the lower the hardness and strength.

For example, high carbon steel has a high hardness and strength, because it has a high carbon content, ranging from 0.6% to 2.1%, depending on the grade. High carbon steel can withstand high stress and pressure, but it is more prone to cracking and breaking. High carbon steel is suitable for applications that require high performance and durability, such as cutting tools, springs, and wires.

Low carbon steel has a low hardness and strength, because it has a low carbon content, ranging from 0.04% to 0.3%, depending on the grade. Low carbon steel can deform and bend easily, but it is more prone to denting and scratching. Low carbon steel is suitable for applications that require high flexibility and formability, such as structural and architectural materials, automotive and transportation components, pipes and tubes.

Stainless steel has a moderate hardness and strength, because it has a moderate carbon content, ranging from 0.03% to 1.2%, depending on the grade. Stainless steel can resist moderate stress and pressure, but it is more prone to work hardening and fatigue. Stainless steel is suitable for applications that require high resistance to rust and corrosion, such as outdoor and marine environments, food and beverage, medical and pharmaceutical, chemical and petrochemical, etc.

Aluminum has a low hardness and strength, because it has a low carbon content, but a high silicon and magnesium content, which improve the strength and hardness of the metal. Aluminum can resist low stress and pressure, but it is more prone to buckling and tearing. Aluminum is suitable for applications that require low weight and high fuel efficiency, such as construction and architecture, automotive and transportation, energy and power, etc.

Copper has a low hardness and strength, because it has a low carbon content, but a high copper content, which reduces the strength and hardness of the metal. Copper can resist low stress and pressure, but it is more prone to stretching and shearing. Copper is suitable for applications that require high electrical and thermal conductivity, such as electrical and electronic, heating and cooling, plumbing and piping, etc.

Richconn is a company well-known for carbon steel processing and has advanced processing equipment and technology. We focus on the processing of carbon steel and have a variety of processing techniques, including stamping, cutting, welding and heat treatment. Our processing capabilities cover a variety of carbon steel materials and can meet the different needs of customers, whether it is customization or mass production. Through strict quality control and efficient production processes, Richconn is committed to providing customers with high-quality carbon steel CNC machining services and has established a good reputation in the industry.

What is a CNC machine? The Precision Way to Modern ManufacturingSeptember 21, 2023CNC machine stands for Computer Numerical Control, which is a manufacturing process that controls the movement of a tool or machine through a computer program.view

What is a CNC machine? The Precision Way to Modern ManufacturingSeptember 21, 2023CNC machine stands for Computer Numerical Control, which is a manufacturing process that controls the movement of a tool or machine through a computer program.view Sheet Metal Bending: Comprehensive Insights from Processes to EconomicsJuly 25, 2024Sheet metal bending holds a significant place in manufacturing. Let’s discover its diverse processes, unique methods, safety aspects, and cost analysis in this comprehensive exploration.view

Sheet Metal Bending: Comprehensive Insights from Processes to EconomicsJuly 25, 2024Sheet metal bending holds a significant place in manufacturing. Let’s discover its diverse processes, unique methods, safety aspects, and cost analysis in this comprehensive exploration.view Choosing the Right Finish for Your CNC PartsSeptember 7, 2023From raw CNC machined parts to a final product that gleams with quality involves a crucial decision – selecting the right surface finish or treatment. Choosing the right surface finish or treatment f...view

Choosing the Right Finish for Your CNC PartsSeptember 7, 2023From raw CNC machined parts to a final product that gleams with quality involves a crucial decision – selecting the right surface finish or treatment. Choosing the right surface finish or treatment f...view How to Maximize the Effectiveness of CNC Machining Technology?August 14, 2023Positive Innovation of Mechanical CNC Machining EquipmentIn order to maximize the application effect of CNC machining technology, it is necessary to analyze the characteristics of CNC machining ODM te...view

How to Maximize the Effectiveness of CNC Machining Technology?August 14, 2023Positive Innovation of Mechanical CNC Machining EquipmentIn order to maximize the application effect of CNC machining technology, it is necessary to analyze the characteristics of CNC machining ODM te...view Methods and Characteristics of Electrophoretic Metal CoatingJune 17, 2024Methods of Electrophoretic Metal CoatingDue to the different nature of electrophoretic metal coating itself, it is divided into two kinds: anodic electrophoretic metal coating and cathodic electrophor...view

Methods and Characteristics of Electrophoretic Metal CoatingJune 17, 2024Methods of Electrophoretic Metal CoatingDue to the different nature of electrophoretic metal coating itself, it is divided into two kinds: anodic electrophoretic metal coating and cathodic electrophor...view What Is CNC Process? CNC Machining Process Design PrinciplesMarch 6, 20231, the maximum concentration of CNC machining process, a positioning principleGenerally in the CNC machine tools, especially in the machining center on the processing parts, the process can be maximal...view

What Is CNC Process? CNC Machining Process Design PrinciplesMarch 6, 20231, the maximum concentration of CNC machining process, a positioning principleGenerally in the CNC machine tools, especially in the machining center on the processing parts, the process can be maximal...view