Galvanized sheet metal is a versatile and cost-effective material that can be used in a variety of applications. It is created by coating steel with zinc, creating a protective barrier against corrosion. Here is an overview of galvanized sheet metal, including different types available, applications, and benefits. Let's get straight to this material!

Galvanized sheet metal is a type of steel product that is coated with zinc to create a protective barrier against corrosion. The process of galvanized metal sheeting results in a product with unique properties and benefits, depending on the type of galvanized sheet metal chosen. It involves immersing the metal in a bath of molten zinc or applying zinc through electroplating. The purpose of galvanizing sheet metal is to provide it with enhanced corrosion resistance. The zinc coating acts as a protective barrier, preventing direct contact between the base metal and corrosive elements such as moisture, oxygen, and chemicals. This helps to significantly extend the lifespan of the metal and reduce the risk of rust and corrosion.

Galvanized sheet metal, also known as galvanized steel, is a versatile material commonly used in various applications due to its durability and corrosion-resistant properties. Here are some common uses:

Roofing: Galvanized sheet metal is widely used for roofing purposes, providing protection against the elements. It is commonly seen in residential, commercial, and industrial buildings.

Construction: It is used in construction projects for cladding, siding, and wall panels. The galvanized coating helps to enhance the longevity and structural integrity of the building.

Gutters and Downspouts: Galvanized sheet metal is often used in the manufacturing of gutters and downspouts. Its corrosion-resistant properties make it suitable for handling rainwater and directing it away from buildings.

HVAC Ductwork: The galvanized sheet metal is used for fabricating ductwork in heating, ventilation, and air conditioning (HVAC) systems. It provides strength, durability, and resistance to moisture.

Automotive Industry: Galvanized sheet metal is used in various parts of automobiles, including body panels, chassis components, and exhaust systems. The galvanized coating protects against rust and increases the lifespan of these parts.

Agricultural Equipment: It is used in the manufacturing of agricultural equipment like grain bins, barns, and fences. The corrosion resistance of galvanized sheet metal makes it ideal for outdoor applications.

Appliances: Galvanized sheet metal is commonly used in appliances such as refrigerators, ovens, and washing machines. It helps to protect the internal components from moisture and extends the lifespan of the appliances.

Industrial Applications: Galvanized sheet metal finds its use in industrial applications like storage tanks, containers, and machine enclosures. The protective coating ensures long-term durability and resistance to corrosion.

It's worth noting that galvanized sheet metal should not be used for food preparation or storage purposes, as the zinc coating may contaminate the food. |

The galvanization process is a method of applying a protective zinc coating to steel or iron to prevent corrosion. There are two primary methods of galvanization:

Hot-Dip Galvanization:

In this process, the steel or iron article is completely immersed in a bath of molten zinc. The metal is cleaned and pre-treated to remove any surface contaminants. Once cleaned, the article is dipped into the molten zinc, which reacts with the steel or iron to form a series of zinc-iron alloy layers. This process creates a strong bond between the zinc coating and the base metal. After dipping, the article is lifted out of the molten zinc, excess zinc is removed, and it is allowed to cool and solidify.

Electro-Galvanization:

This process involves the use of an electrolyte solution containing zinc ions. The steel or iron article is cleaned and pre-treated to ensure a clean surface. It is then immersed in the electrolyte solution, and an electrical current is passed through it. This causes the zinc ions to be deposited onto the surface of the metal, forming a thin, uniform zinc coating. The thickness of the coating can be controlled by adjusting the duration of the electro-galvanizing process.

Both hot-dip galvanization and electro-galvanization provide a layer of zinc coating that acts as a sacrificial barrier, preventing direct contact between the steel or iron and the corrosive elements in the environment. The zinc coating corrodes first, protecting the underlying metal from rust and other forms of corrosion. The resulting galvanized steel or iron is highly resistant to rust and has an extended lifespan compared to untreated metal.

It's important to note that the galvanization process may vary depending on the specific requirements of the application and the type of metal being galvanized. |

Galvanized metal sheets are available in many different sizes. Specific specifications and standards for galvanized sheet metal may vary depending on the region, industry, and application.

Coating Thickness:

The thickness of the zinc coating on galvanized sheet metal is typically specified in terms of coating weight, which is expressed in ounces per square foot (oz/ft²) or grams per square meter (g/m²). Common coating weights range from G30 (0.3 oz/ft² or 90 g/m²) to G275 (2.75 oz/ft² or 840 g/m²), with G90 (0.9 oz/ft² or 275 g/m²) being a commonly used standard.

Steel Grade:

Galvanized sheet metal is typically made from carbon steel or low-alloy steel. The steel grade affects the overall strength and performance of the galvanized sheet metal.

Surface Finish:

Galvanized sheet metal has a characteristic spangled appearance due to the formation of zinc crystals on the surface during the galvanization process. This spangled finish can vary in size and density, depending on the specific galvanization process used.

Tensile Strength:

The tensile strength of galvanized sheet metal refers to its ability to resist deformation under tension. It is an important factor in determining the structural integrity and load-bearing capacity of the material. The tensile strength of galvanized sheet metal can vary depending on the steel grade and thickness.

Width and Length:

Galvanized sheet metal is available in various widths and lengths to meet specific project requirements. Common widths range from 24 inches to 48 inches, while lengths can vary from several feet to several hundred feet.

Thickness:

Galvanize sheet metal comes in different thicknesses, commonly expressed in gauge or decimal inches. The thickness can range from thin gauges (e.g., 26 gauge or 0.0187 inches) to thicker gauges (e.g., 16 gauge or 0.0598 inches).

Tip: Consulting relevant industry standards or manufacturers' guidelines can provide more detailed information on the specifications of galvanized sheet metal.

As you can see, galvanized sheet metal offers several benefits that make it a popular choice in various industries and applications. Some of the key benefits of galvanized sheet metal include:

Corrosion Resistance:

The zinc coating on galvanized sheet metal provides excellent corrosion resistance. It acts as a protective barrier, preventing direct contact between the steel or iron base metal and corrosive elements such as moisture, oxygen, and chemicals. This helps to significantly extend the lifespan of the metal and reduce maintenance costs.

Durable and Long-lasting:

Galvanized sheet metal is highly durable and can withstand harsh environmental conditions. The zinc coating provides an added layer of protection against abrasion, impact, and weathering. It is resistant to rust, scratches, and fading, making it suitable for both indoor and outdoor applications.

Cost-effective:

Galvanized sheet metal is a cost-effective choice compared to other corrosion-resistant metals. The initial investment in galvanization pays off in the long run due to the extended lifespan and reduced maintenance requirements. It eliminates the need for additional coatings or frequent replacements, resulting in cost savings over time.

Versatility:

Galvanized sheet metal is available in various thicknesses, widths, and lengths, allowing for customization to specific project requirements. It can be easily formed, cut, welded, and fabricated into different shapes and sizes, making it versatile for a wide range of applications across industries such as construction, automotive, agriculture, and manufacturing.

Sustainable and Recyclable:

Galvanized sheet metal is an environmentally friendly choice. The galvanization process uses a non-toxic zinc coating, making it safe for both humans and the environment. Additionally, galvanized steel is 100% recyclable, reducing the demand for new raw materials and minimizing waste.

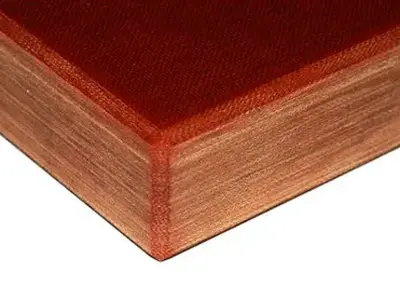

Aesthetic Appeal:

Galvanized sheet metal offers a distinctive appearance with its spangled finish, giving it a unique and attractive look. It can be further enhanced with various finishes such as paint, powder coating, or clear coatings to achieve different colors and textures, allowing for creative design possibilities.

These benefits make galvanized sheet metal a reliable and cost-effective option for applications that require durability, corrosion resistance, and longevity.

Yes, galvanized steel can be painted. However, you should use the right tools and methods. Some considerations that should be kept in mind include proper surface preparation, etching, priming, paint selection, etc.

Yes, welding galvanized steel is a useful technique for sheet metal fabrication. However, please note that welding galvanized steel may affect the integrity of the surrounding zinc coating and reduce its corrosion resistance. Therefore, it is recommended to plan and execute the welding process carefully. Don't ignore the potential impact on the galvanized steel's protective properties.

There are several finishes that can be applied to galvanized sheet metal to enhance its appearance or provide additional protection. Some common finishes used on galvanized sheet metal include powder coating, clear coating, varnish, galvannealing, embossing or patterned finishes, etc. The choice of finish depends on the specific application and desired aesthetic appearance.

There you have it! Galvanized sheet metal has plenty of advantages, from durability to corrosion resistance. Additionally, it has a wide range of applications that may be used in many other sectors. Galvanized sheet metal is your best option when you need a material with one of the best rust protection.

Richconn provides on-demand and affordable sheet metal prototyping services. For both low-volume prototypes and high-volume manufacturing, Richconn offers the best services with timely delivery and strong manufacturing capabilities. Simply submit your design file and define your needs to receive a fast quote. Depending on what you want, we also offer professional expert analysis.

Six Key Points of CNC MachiningApril 4, 2023Many manufacturers know that in the process of CNC machining center, it is crucial to avoid collisions when programming and operating the machine tool. After all, CNC machining centers are not cheap, ...view

Six Key Points of CNC MachiningApril 4, 2023Many manufacturers know that in the process of CNC machining center, it is crucial to avoid collisions when programming and operating the machine tool. After all, CNC machining centers are not cheap, ...view What Are the Processing Principles of Precision Machining?December 30, 2022What are the processing principles of precision CNC machining? What safety precautions are there when performing precision CNC machining?1. Processing principles of precision NC machining (1) In order...view

What Are the Processing Principles of Precision Machining?December 30, 2022What are the processing principles of precision CNC machining? What safety precautions are there when performing precision CNC machining?1. Processing principles of precision NC machining (1) In order...view CNC Axis TypesSeptember 28, 2022IntroductionCNC stands for “computer numerical control” and is a type of machine tool that uses encoded commands to operate various milling and cutting operations. The use of CNC machines has increa...view

CNC Axis TypesSeptember 28, 2022IntroductionCNC stands for “computer numerical control” and is a type of machine tool that uses encoded commands to operate various milling and cutting operations. The use of CNC machines has increa...view Evaluation of UV-resistant Plastic OptionsOctober 17, 2023Everyone knows that sun protection is important when laying out on the beach or spending a relaxing Saturday afternoon fishing. That's because the sun's ultraviolet (UV) rays can cause serious damage to unprotected skin, resulting in a painful sunburn or worse. Polymers are similarly damaged by UV radiation, albeit more slowly and far less dramatically than in humans.view

Evaluation of UV-resistant Plastic OptionsOctober 17, 2023Everyone knows that sun protection is important when laying out on the beach or spending a relaxing Saturday afternoon fishing. That's because the sun's ultraviolet (UV) rays can cause serious damage to unprotected skin, resulting in a painful sunburn or worse. Polymers are similarly damaged by UV radiation, albeit more slowly and far less dramatically than in humans.view CNC Machining Titanium: Precision Craftsmanship and ApplicationsNovember 6, 2023Are you ready to dive into the world of CNC machining titanium? If you're an engineer, designer, or manufacturer seeking to master the art of CNC machining this remarkable metal, you've come to the right place. In this article, I will guide you through the intricacies of CNC machining titanium, offering valuable insights, best practices, and real-world applications.view

CNC Machining Titanium: Precision Craftsmanship and ApplicationsNovember 6, 2023Are you ready to dive into the world of CNC machining titanium? If you're an engineer, designer, or manufacturer seeking to master the art of CNC machining this remarkable metal, you've come to the right place. In this article, I will guide you through the intricacies of CNC machining titanium, offering valuable insights, best practices, and real-world applications.view Bakelite: The First Synthetic Plastic and Its ApplicationsDecember 7, 2023Bakelite is a synthetic material that was invented in the early 20th century by Leo Baekeland, a Belgian-American chemist. Bakelite is considered to be the first true plastic, as it was the first material that was not derived from natural sources, such as cellulose, rubber, or horn.view

Bakelite: The First Synthetic Plastic and Its ApplicationsDecember 7, 2023Bakelite is a synthetic material that was invented in the early 20th century by Leo Baekeland, a Belgian-American chemist. Bakelite is considered to be the first true plastic, as it was the first material that was not derived from natural sources, such as cellulose, rubber, or horn.view

EN

EN

ru

ru