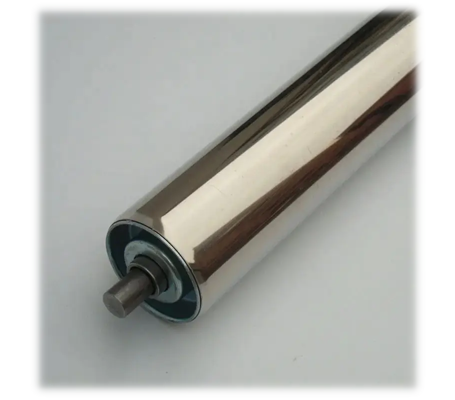

Nickel plated rollers and chrome plated rollers are two common electroplated roller products, widely used in printing, electronics, automobiles and other industries. Do you know the differences between them? This manual comprehensively dissects the differences between nickel plated rollers and chrome plated rollers in terms of plating material, application environment, characteristics, etc., to help you correctly choose the right electroplated roller.

Rollers play a crucial role in industrial production and other fields. Among them, nickel plated rollers and chrome plated rollers are common roller types, each with unique characteristics and applications. This article will delve into the differences between these two types of rollers, to help you better understand their advantages and applicable scopes.

As common roller types in industrial production, nickel plated rollers and chrome plated rollers have some significant differences in materials, performance, and applications:

Nickel plated rollers are typically made of a steel substrate plated with a layer of nickel, with a nickel-plating layer thickness of 10-50um. Chrome plated rollers have a chromium plating layer with a thickness of 50-300um. This makes the rollers more wear-resistant, corrosion-resistant, and with higher thermal conductivity during use. In contrast, chrome plated rollers have a layer of chromium plated on a steel substrate. This gives chrome plated rollers higher hardness and wear resistance, suitable for more demanding working conditions.

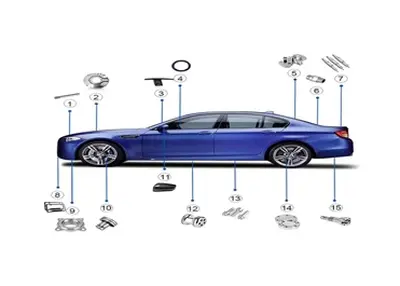

Nickel plated rollers are more suitable for the electronics industry, such as PCB manufacturing. Chrome plated rollers are more commonly used in printing, packaging, automotive manufacturing and other occasions requiring high wear resistance and corrosion resistance.

- The nickel-plating layer is relatively soft with good flex fatigue resistance; the chrome plating layer has higher hardness and better load-bearing capability and compressive strength.

- Nickel-plating has excellent conductivity; chrome plating has better heat insulation and high temperature resistance.

The nickel-plating process is simple, while the chrome plating process is more complex, requiring precise control of process parameters such as current density and temperature.

Nickel plated rollers exhibit superior corrosion resistance due to the nickel layer, making them an ideal choice for chemical production processes involving contact with chemicals. The chromium layer of chrome plated rollers also provides excellent corrosion resistance, allowing stable performance in humid or corrosive environments.

Chrome plated rollers excel in hardness and wear resistance. The addition of chromium makes the roller surface harder to withstand high pressure and friction. This makes chrome plated rollers especially popular in metalworking. Although nickel plated rollers also have high hardness, they may suffer some abrasion under extreme conditions.

Nickel plated rollers are often used in temperature controlled production processes due to their good thermal conductivity, which ensures uniform heating of materials and improves production efficiency. However, chrome plated rollers have lower thermal conductivity and may take more time to achieve uniform heating.

Chrome plated roller surfaces are usually smoother than nickel plated rollers. This makes chrome plated rollers excel in high precision machining applications such as printing. Nickel plated rollers have relatively rough surfaces suitable for applications without extremely high smoothness requirements.

Due to their different characteristics, nickel plated rollers and chrome plated rollers play important roles in different application fields:

Chemical production: Corrosion resistance makes nickel plated rollers an ideal choice for chemical production involving contact with various chemicals.

Food processing: The food industry often requires high sanitary standards, to which nickel-plated rollers' corrosion resistance and thermal conductivity are applicable.

Plastics processing: Plastics production makes high demands on rollers, which nickel plated rollers can meet in wear resistance and corrosion resistance.

Papermaking: The thermal conductivity of nickel-plated rollers facilitates paper drying and processing, improving production efficiency.

Metalworking: The hardness and wear resistance make chrome plated rollers widely used in metalworking to withstand high pressure and friction.

Printing: The printing industry requires smooth surfaces for printing plates, to which chrome plated rollers' smoothness is applicable.

Leather processing: In leather pressing, chrome plated rollers provide the required pressure and temperature to ensure product quality.

Plastics extrusion: The wear resistance and thermal conductivity of chrome plated rollers are crucial for efficiency in plastics extrusion.

Chrome plated rollers are more wear resistant. Their hard chromium layer allows them to maintain surface integrity under high pressure and friction, making them more suitable for applications requiring wear resistance.

Nickel plated rollers have better thermal conductivity for uniform heating of materials. Chrome plated rollers have relatively poorer thermal conductivity and may take longer to achieve uniform heating.

H3 What industries are nickel plated rollers and chrome plated rollers suitable for?

Nickel plated rollers are suitable for chemical, food processing, plastics processing, and papermaking industries. Chrome plated rollers are suitable for metalworking, printing, leather processing, and plastics extrusion.

Generally, chrome plated rollers have higher manufacturing costs due to their plating process and hardness requirements. Nickel plated rollers have relatively lower costs, but specific costs depend on factors like materials and dimensions.

Yes, both nickel plated rollers and chrome plated rollers exhibit outstanding corrosion resistance due to their surface plating allowing long term stable operation in humid, corrosive environments.

In some specific applications, nickel plated rollers and chrome plated rollers may have some interchangeability. However, due to their differences in materials, performance, and applications, it is best to choose suitable roller types based on specific requirements.

For the same specifications, chrome plated rollers are typically 1.5-2 times more expensive than nickel plated rollers. The complex process and higher cost of chromium also contribute to their higher prices.

The nickel-plating layer thickness for nickel plated rollers is typically 10-50um. The thickness can be customized based on application requirements.

The surface hardness of chrome plated rollers is approximately 700-1100HV, depending on the composition and thickness of the chromium plating layer.

Heavily worn chrome plated rollers can be re-chromed to extend service life. Precision grinding can also be done to refurbish the surface.

þ Machining of various metal rollers

Can machine rollers of various metal materials such as steel, stainless steel, copper, aluminium rolls, etc. Providing turning, grinding, milling, boring, polishing and other processing methods.

þ Surface treatment

Can provide various industrial plating treatments for rollers, such as chrome plating, nickel plating, coating, etc. to improve roller performance.

þ Repair and maintenance

Repair and refurbish worn and damaged rollers, including stripping, straightening, polishing, plating restoration, etc. to prolong service life.

þ Custom design and manufacturing

As a leading CNC China company, Richconn designs and manufactures various non-standard rollers according to customer-specific requirements to meet personalized needs.

þ Precision control

Use precision inspection equipment to control key dimensions to a machining accuracy of 0.002mm.

þ Fast delivery

Advanced machining equipment guarantees delivery time to meet customer needs.

þ One-stop service

From material procurement, design solutions, machining and manufacturing to after-sales maintenance, provide one-stop roller solutions.

With an experienced technical team and advanced equipment, we can provide personalized, high-quality roller machining services on demand. Please feel free to contact us for inquiries!

How CNC Automotive Parts Elevate Vehicle FunctionalityJanuary 5, 2024When it comes to the automotive industry, precision and performance are of utmost importance. Manufacturers are constantly striving to enhance the functionality of vehicles, which relies heavily on th...view

How CNC Automotive Parts Elevate Vehicle FunctionalityJanuary 5, 2024When it comes to the automotive industry, precision and performance are of utmost importance. Manufacturers are constantly striving to enhance the functionality of vehicles, which relies heavily on th...view CNC Machining Technology and ProcessJuly 27, 2023CNC Machining TechnologyCNC machining technology mainly includes CNC machine tool machining technology and CNC machine tool programming technology. CNC machine tool machining technology directly compl...view

CNC Machining Technology and ProcessJuly 27, 2023CNC Machining TechnologyCNC machining technology mainly includes CNC machine tool machining technology and CNC machine tool programming technology. CNC machine tool machining technology directly compl...view CNC Machining Services and Engineered Machined Products: Meeting Manufacturing NeedsNovember 7, 2023Are you looking to understand the world of CNC machining and engineered machined products better? You're in the right place! I'm here to guide you through the intricate world of CNC machining, engineered machined products, and how Richconn can be your trusted partner in this journey.view

CNC Machining Services and Engineered Machined Products: Meeting Manufacturing NeedsNovember 7, 2023Are you looking to understand the world of CNC machining and engineered machined products better? You're in the right place! I'm here to guide you through the intricate world of CNC machining, engineered machined products, and how Richconn can be your trusted partner in this journey.view Authoritative Guide to Tack Welding & Efficient Welding ProcessSeptember 19, 2023Welding is a long-standing process that remains essential in various industries. Manufacturers employ different types of welds depending on the project's requirements. Tack welding is particularly...view

Authoritative Guide to Tack Welding & Efficient Welding ProcessSeptember 19, 2023Welding is a long-standing process that remains essential in various industries. Manufacturers employ different types of welds depending on the project's requirements. Tack welding is particularly...view The Features and Characteristics of CNC Milling MaterialsFebruary 29, 2024CNC milling, a cornerstone in the manufacturing processes of various industries, hinges significantly on the selection of materials.view

The Features and Characteristics of CNC Milling MaterialsFebruary 29, 2024CNC milling, a cornerstone in the manufacturing processes of various industries, hinges significantly on the selection of materials.view Unraveling the World of Machined Springs: Your Ultimate GuideNovember 9, 2023As a CNC machining service provider, we at Richconn understand the significance of precision engineering and how it's all about the details. In the realm of mechanical components, one topic that piques the curiosity of engineers, manufacturers, and professionals alike is -Machined Springs. In this comprehensive guide, I will walk you through the intricacies of Machined Springs, from the fundamentals to their applications, performance characteristics, manufacturing processes, and more.view

Unraveling the World of Machined Springs: Your Ultimate GuideNovember 9, 2023As a CNC machining service provider, we at Richconn understand the significance of precision engineering and how it's all about the details. In the realm of mechanical components, one topic that piques the curiosity of engineers, manufacturers, and professionals alike is -Machined Springs. In this comprehensive guide, I will walk you through the intricacies of Machined Springs, from the fundamentals to their applications, performance characteristics, manufacturing processes, and more.view

EN

EN

ru

ru