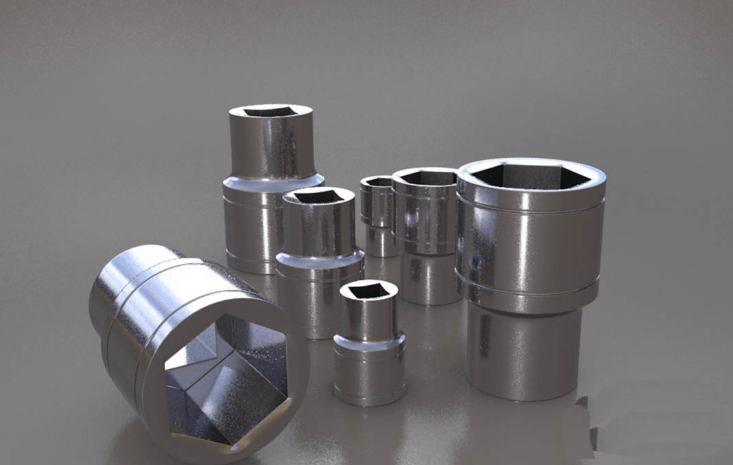

Sleeve parts machining charges will be involved in the structural design, machining process, hole size, material selection and other requirements, any one of the different processing needs will lead to a great difference in price, so the need for a relatively accurate quote must provide a complete design drawings, engineers will be based on the design of the drawings labeled materials, dimensions, process, accuracy, structure, table at the detailed parameters such as calculating the accurate quote. If you have already designed the drawings can be uploaded in Richconn, Richconn's CNC machining engineers can quickly provide you with accurate quotes.

The following are some key matters about the processing of sleeve parts, which are also important factors affecting the price;

The first thing to consider is the cost of the material used, different types of metal, alloy or plastic materials have different prices. Material selection criteria is the first to take into account the environment in which the parts are used, the harsh environment of the material requirements will be more stringent, followed by the consideration of more economical alternative products.

If the processing of parts is more complex, requiring multiple steps, multiple processes or special tools, then the cost may increase accordingly. Often times it seems like a simple part for

Why so expensive? In fact, the complexity of the process is an extremely unintuitive charges, which is only understood by those who know the industry, so the factory in the offer is also necessary to explain clearly with customers.

Batch production usually reduces the cost per unit part because the setup and preparation costs of the production line can be amortized over more parts. Therefore, any factory is sampling is very expensive batch production will be much cheaper, speed plus in the solution to the problem of sampling expensive to provide a good program; is sampling according to the normal offer charges, when the customer sampling product validation in the speed plus batch production can be directly subtracted from the cost of the previous sampling.

The type and precision of processing equipment used will also affect the price. More advanced and precise equipment may increase the cost, but usually can provide higher quality parts.

Operating the equipment, overseeing the production process, and quality control all require labor input, so labor costs are also a consideration. If the part has special design requirements, such as close tolerances, special surface treatments or coatings, this may also affect processing costs.

If parts need to be machined urgently and delivered on short notice, additional overtime or expedited production may be required, resulting in higher costs.

Current market supply and demand and competitive conditions can also affect prices.

The most common practice is to contact the precision machine shop with detailed specifications and requirements for the part so they can provide you with an accurate quote. Different manufacturers may have different pricing strategies, so it is best to consult with more than one manufacturer for better comparison and selection.

What Is A Coordinate Measuring Machine Used For?July 16, 2024A coordinate measuring machine is often used to qualify rapid prototypes and production parts that have complex geometries with tight tolerances. Learn more about it to ensure every part you make meets and exceeds your expectations.view

What Is A Coordinate Measuring Machine Used For?July 16, 2024A coordinate measuring machine is often used to qualify rapid prototypes and production parts that have complex geometries with tight tolerances. Learn more about it to ensure every part you make meets and exceeds your expectations.view How to Remove Chrome Plating Easily? (A Complete Guide 2024)March 11, 2024Learn how to remove chrome plating effectively with our comprehensive guide and get expert tips for successfully stripping chrome from metal surfaces.view

How to Remove Chrome Plating Easily? (A Complete Guide 2024)March 11, 2024Learn how to remove chrome plating effectively with our comprehensive guide and get expert tips for successfully stripping chrome from metal surfaces.view The Benefits of Anodizing Precision Machined Aluminum ProductsOctober 19, 2023Why might you want to anodize aluminum? There are several good reasons to consider anodizing aluminum parts. Anodizing aluminum creates a layer of oxide and forms a layer on the surface of the aluminum.view

The Benefits of Anodizing Precision Machined Aluminum ProductsOctober 19, 2023Why might you want to anodize aluminum? There are several good reasons to consider anodizing aluminum parts. Anodizing aluminum creates a layer of oxide and forms a layer on the surface of the aluminum.view What Is Anodizing: Exploring the Anodizing Process and TypesAugust 31, 2023Anodizing goes beyond surface enhancement; it represents an extraordinary electrochemical transformation that endows a diverse range of metals with exceptional characteristics. If you've ever wond...view

What Is Anodizing: Exploring the Anodizing Process and TypesAugust 31, 2023Anodizing goes beyond surface enhancement; it represents an extraordinary electrochemical transformation that endows a diverse range of metals with exceptional characteristics. If you've ever wond...view What Will Determine the Precision of CNC Machining?August 10, 2022In the preparation of CNC machining programs, proper use of methods and techniques is of great significance to ensure and improve the machining accuracy of CNC machine tools. So what determines the ma...view

What Will Determine the Precision of CNC Machining?August 10, 2022In the preparation of CNC machining programs, proper use of methods and techniques is of great significance to ensure and improve the machining accuracy of CNC machine tools. So what determines the ma...view 5-Axis CNC Machining: Faster Speeds and Higher PrecisionJuly 27, 2023One of the ambitious goals of the manufacturing industry is to complete processing in one go: putting a piece of material into a machine tool, running a program, and finally obtaining a perfectly Mach...view

5-Axis CNC Machining: Faster Speeds and Higher PrecisionJuly 27, 2023One of the ambitious goals of the manufacturing industry is to complete processing in one go: putting a piece of material into a machine tool, running a program, and finally obtaining a perfectly Mach...view

EN

EN

ru

ru