If you find the vast selection of different materials for CNC machining confusing, this blog will tell you how to reduce that number to a manageable level.

Choosing the right material for CNC machining can make all the difference in getting a working part or prototype made at a reasonable price.

If you have to wade through a multitude of data sheets, you should

Start by weighting the requirements of the custom machined parts you want to manufacture. First, think about which features are essential, and then consider which would be desirable. This will allow you to quickly go through the data sheets and reduce the choices to a manageable level.

First, understand what the most common material properties are.

Starch. There are several different types of strength.

One of the most common is tensile strength. Ultimate Tensile Strength (UTS) indicates the tensile load at which an object will break. Fracture strength is measured in megapascals (MPa) or newtons per square meter. A material with low tensile strength typically has an MPa value of less than 100, while a high-strength material has a value of more than 400.

Impact strength or toughness may be another important consideration, and the part may also need to be hard and wear-resistant. Friction can also play an important role. Here, the spectrum ranges from materials with high friction to those that are low-friction and self-lubricating.

At first, you may be considering a material that resists wear and/or abrasion. However, you should not ignore the fact that wear-resistant materials are also difficult to machine. It will take more time and require more tooling to produce the part you need. In other words, it will cost you more. This is what we mean by the term "machinability".

Strength is important, but in modern manufacturing you often need materials that have a good strength-to-weight ratio. Therefore, you should also consider material density or material weight. This is simply the ratio of weight to volume. This value is often given in kilograms per cubic meter.

This refers to the ability of a material to return to its original shape after being stretched or compressed. Material descriptions contain common terms relating to elasticity. For example, low elasticity is described as plastic, medium elasticity as deformable or tough, and high elasticity as stiff or brittle.

Elongation refers to the changed length of a part compared to its original size. In other words, to its stretchability. One often encounters a value that provides information about the so-called elongation at break or elongation at tear. It indicates the length of an object in relation to its original length when it breaks or tears.

The operating temperature is the temperature at which a device operates. For plastics, this specification can be further subdivided into a short-term operating temperature (short-term tolerance in minutes or sometimes hours) and a long-term operating temperature.

You may also need to consider the melting temperature of your chosen material.

This value refers to the ability of a material to conduct or transfer heat. In some applications, thermal conductivity is quite desirable, while in others it should be prevented (for example, by insulation).

The ability of a material to conduct electrical current. For example, copper is a good conductor. In contrast, most plastics are poor conductors or excellent insulators.

Given the variety of different metals and plastics, you'll notice that some are more popular than others. Here is a selection of the most common options.

Titanium is the top choice in aerospace engineering because it is strong, wear-resistant and lightweight. The problem is that it is difficult to machine, and parts made from it cost significantly more than those made from aluminum or stainless steel. Consequently, you should consider a less costly metal if it doesn't have to be titanium.

Aluminum alloys are easy to machine, have a good strength-to-weight ratio, and are corrosion resistant (especially when anodized). They are widely used in the manufacture of aircraft parts, but also in mechanical engineering, as well as in the production of computer components, cookware and many other applications. It is worth taking a look at the specific properties of various alloys of this metal: The 6000 series is, in a sense, the workhorse, while the 7000 series is stronger and 2000 is intentionally softer to increase fatigue resistance.

Stainless steel comes in numerous different grades and qualities to consider. They are all known for their corrosion resistance and excellent mechanical properties.

Alloy 17-4PH. PH stands for Precipitation Hardenable. Aside from being a stainless steel alloy, this alloy is also very durable, making it well suited for harsh environments where the part may be subject to wear and corrosion. It is used in mold making, aerospace, missile, chemical, food processing, and oil and gas platforms. These alloys are hard and correspondingly expensive to machine.

Two common grades of stainless steel are 304 (also known as A2) and 316 (A4 or marine grade). 304 is stronger and less expensive, while 316 is more corrosion resistant.

The various stainless steels have very different machinability, but all take longer to machine than aluminum.

Other metals worth considering are mild and mild steel alloys, as well as copper and brass. They are all suitable for CNC machining, although some are harder and therefore more costly to machine than others.

ABS plastic is suitable for both injection molding and machining and offers excellent toughness and impact resistance.

An engineering plastic with high mechanical strength, dimensional stability and comparatively low cost. This combination makes it the most widely used material, for example in gears and sporting goods.

Another excellent material is nylon, which combines strength with flexibility. It is used in numerous technical areas, for example in the automotive industry as well as in mechanical engineering.

This material is often used as a substitute for metal. It is the all-rounder plastic from which high-end components for aerospace, Formula 1 and medical technology are made. It offers high abrasion and wear resistance, low moisture absorption and a low coefficient of friction.

This is one of the most widely used materials in modern manufacturing. It has excellent impact resistance and good temperature resistance and is a real alternative to glass. Polycarbonate and acrylic are naturally transparent, but processing leaves a matte finish. The clarity of the material can be restored by polishing.

Admittedly: Choosing the right material can be time-consuming, but with a little research, you can increase the number of materials you're familiar with. As your personal list grows longer, you may save money or come across a material that better suits the needs of the part you want to make. Richconn has already done much of this research for you. The result: 30+ of the most popular materials hand-picked for you.

Selecting a metal or plastic material for CNC machining part can be challenging. Keep the intended function in mind and don't discount any post-processing options.

If you have any questions about our services at Richconn, please contact an applications engineer at sales@richconn.com.cn or +86-0755-28025755. Have a finished design for 3D printing? Upload it now to get a quote.

How to Find an Excellent Precision Machining Manufacturer in China?October 19, 2023China is one of the more developed countries in the global manufacturing industry, so it is not difficult to find an excellent precision machining manufacturer in China, but how to find a reliable quality, good service, reasonable price precision machining manufacturer in China, it is necessary for consumers to make a careful assessment when choosing.view

How to Find an Excellent Precision Machining Manufacturer in China?October 19, 2023China is one of the more developed countries in the global manufacturing industry, so it is not difficult to find an excellent precision machining manufacturer in China, but how to find a reliable quality, good service, reasonable price precision machining manufacturer in China, it is necessary for consumers to make a careful assessment when choosing.view The Features and Characteristics of CNC Milling MaterialsFebruary 29, 2024CNC milling, a cornerstone in the manufacturing processes of various industries, hinges significantly on the selection of materials.view

The Features and Characteristics of CNC Milling MaterialsFebruary 29, 2024CNC milling, a cornerstone in the manufacturing processes of various industries, hinges significantly on the selection of materials.view From Blueprint to Reality: The Role of 3D Printing in ArchitectureOctober 10, 2023The architecture industry is undergoing profound change thanks to 3D printing. Architects are harnessing this technology to revolutionize the way they design, construct and experience buildings. With 3D printing, architects can transform digital designs into tangible objects, opening up endless possibilities.view

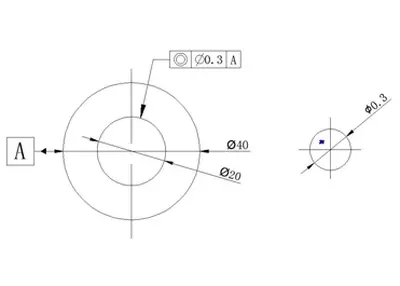

From Blueprint to Reality: The Role of 3D Printing in ArchitectureOctober 10, 2023The architecture industry is undergoing profound change thanks to 3D printing. Architects are harnessing this technology to revolutionize the way they design, construct and experience buildings. With 3D printing, architects can transform digital designs into tangible objects, opening up endless possibilities.view Positioning control - concentricity/coaxialityNovember 17, 2023When manufacturing cylindrical CNC milled parts, concentricity is the unit of measure of part accuracy. Concentricity, is the degree to which the inner diameter of the insert is offset from the center of the entire circle.view

Positioning control - concentricity/coaxialityNovember 17, 2023When manufacturing cylindrical CNC milled parts, concentricity is the unit of measure of part accuracy. Concentricity, is the degree to which the inner diameter of the insert is offset from the center of the entire circle.view Machining outsourcing: advantages and disadvantages of full analysisNovember 16, 2023Machining Outsourcing is a common business model in the manufacturing industry that takes a company's machining needs and gives them to another outside supplier that specializes in machining.view

Machining outsourcing: advantages and disadvantages of full analysisNovember 16, 2023Machining Outsourcing is a common business model in the manufacturing industry that takes a company's machining needs and gives them to another outside supplier that specializes in machining.view Custom Machined Metal Parts: Precision at Your FingertipsNovember 9, 2023Do you crave perfection in your machinery? Are you seeking the ideal metal components for your projects? You've come to the right place! Welcome to Richconn, your reliable partner for custom machined metal parts. In this comprehensive guide, we'll explore the world of precision engineering, from understanding the basics to choosing the right materials, processes, and designs.view

Custom Machined Metal Parts: Precision at Your FingertipsNovember 9, 2023Do you crave perfection in your machinery? Are you seeking the ideal metal components for your projects? You've come to the right place! Welcome to Richconn, your reliable partner for custom machined metal parts. In this comprehensive guide, we'll explore the world of precision engineering, from understanding the basics to choosing the right materials, processes, and designs.view

EN

EN

ru

ru