For computer enthusiasts, the mechanical keyboard's metal texture and the sound of that mechanical equipment is a keyboard users a kind of enjoyment, mechanical keyboard bezel styling design is one of my favorite hardware configurations, especially glazed, computer typing is very indulgent. Nowadays DIY keyboard has become a great pleasure for computer enthusiasts, design program preferences are increasingly very important. Sometimes, picking a suitable keyboard frame this is such a headache. In the next few minutes, Richconn will show you the advantages of aluminum keyboard cases and how to choose one.

After we introduce you to the DIY aluminum mechanical keyboard case, you will know more about it. We don't just cover everything you want to know about aluminum mechanical enclosures, we also provide you with our quality precision manufacturing services to make your DIY journey smoother.

The aluminum alloy keyboard shell we often talk about is a CNC machined customized shell on the alloy, usually with keycaps. The keyboard is just one way we connect in communication. It can be said that the key to keyboard protection is as important as the keyboard.

In fact, the trend of aluminum alloy has long become one of the most important metal materials in electronic devices. The development of aluminum alloy is due to its specific advantages.

Aluminum is relatively light in comparison with other metal materials. For example, it is three times lighter than steel.

Aluminum is easy to recycle. Therefore, it is best to consider applying aluminum. Recycling means that you can reuse it again if necessary.

We know that electronic products get hot when they are used for a long time, so we consider heat dissipation when choosing materials. Aluminum enclosures are able to dissipate heat from the keyboard's structure better. Since aluminum removes heat faster than other metals, this means that you can use this type of keyboard case anywhere.

Picking the right keyboard is likely to be tough for you. As a result, it is considered just the right amount of important to fully consider the benefits of aluminum keyboard cases. The benefits of aluminum keyboard cases include but are not limited to the following.

The anodized finish of the aluminum keyboard case not only provides excellent scratch resistance, but also comes in a wide variety of colors, which enhances the artistic beauty of the product.

After anodizing, the aluminum alloy reflects with gas and gives a rust-proof treatment layer. This means that rusting is not a problem for the keyboard case.

Aluminum keyboard cases are more durable than their counterparts. As a matter of fact, aluminum keyboard housings stand up to the wear and tear of time, while remaining strong at the same time.

Aluminum is a chemical molecule obtained from the right rock formations. Aluminum also comes with an aluminum alloy that makes it popular for keyboard case applications. This represents the fusion of two or more diverse metallic materials to produce the raw material. For the sake of understanding, want me to categorize aluminum profiles by their physical characteristics. Some of the most commonly used types of aluminum are:

You are able to call 6061 aluminum all-purpose. 6061 aluminum has been on the sales market. It has made it a popular choice for manufacturers. 6061 aluminum is a better choice for making keyboard cases. It has excellent compressive strength, moderator corrosion, high weldability and craftability. In situations where compressive strength and corrosion resistance are essential elements, 6061 aluminum is the preferred choice. Their excellent surface treatment also makes them a stronger choice for customers.

This type is basically similar to the 6061 type. Though this is basically similar to 6061, it is more suitable for the main purpose of engineering and construction. They are also used for exterior and interior design solutions.

5052 also has exceptional qualities. Like 6061, it has greater smoothness and corrosion resistance. The drawback of this type of aluminum is that it cannot be manufactured. The heat treatment process is not a solution for this type of aluminum.

Other types of aluminum, such as 5053, 7075, and 6053, can also be used to make keyboard housings, but they are not as common.

In our combing of aluminum alloy mechanical keyboard, you should know some understanding of the mechanical frame of aluminum alloy, choose aluminum alloy mechanical keyboard shell is not only we for the appearance of the wonderful, we have to go to the choice of his materials, functionality and environmental protection and post-processing of the comprehensive consideration.

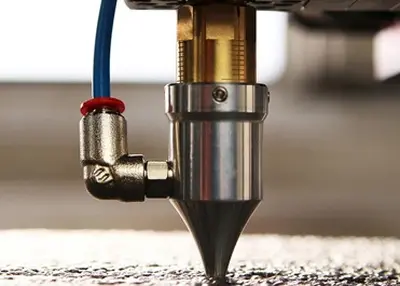

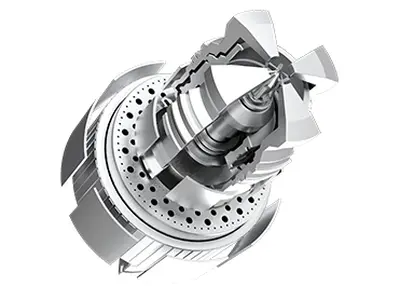

CNC turning service or CNC milling service can be used for small quantities, and die-casting + CNC machining is used for large quantities. No matter how much quantity you need, we have the corresponding cost-effective solutions.

Carbon Steel: Types, Properties, and UsesDecember 8, 2023Carbon steel is one of the most common and widely used materials in the world, thanks to its low cost, high strength, and versatility.view

Carbon Steel: Types, Properties, and UsesDecember 8, 2023Carbon steel is one of the most common and widely used materials in the world, thanks to its low cost, high strength, and versatility.view 3-Axis Vs 4-Axis Vs 5-Axis CNCJuly 21, 20233-axis machiningThree axis CNC machining is the most basic, commonly used in the machinery manufacturing industry is one of the most important processing methods. Common understanding is: accurate lin...view

3-Axis Vs 4-Axis Vs 5-Axis CNCJuly 21, 20233-axis machiningThree axis CNC machining is the most basic, commonly used in the machinery manufacturing industry is one of the most important processing methods. Common understanding is: accurate lin...view What Is Laser Engraving And How Does Laser Engraving Work?March 20, 2024Laser engraving is one of the laser processing technologies. Before using the technology in your project, read this article to get all the information you need to know.view

What Is Laser Engraving And How Does Laser Engraving Work?March 20, 2024Laser engraving is one of the laser processing technologies. Before using the technology in your project, read this article to get all the information you need to know.view How to choose the right material for cnc cnc machining parts?November 1, 2023In the field of CNC numerical control machining, the correct selection of suitable materials is crucial to the performance, accuracy and durability of parts. Different environments and application scenarios require different types of materials, and the following will analyze how to choose the right material from several aspects.view

How to choose the right material for cnc cnc machining parts?November 1, 2023In the field of CNC numerical control machining, the correct selection of suitable materials is crucial to the performance, accuracy and durability of parts. Different environments and application scenarios require different types of materials, and the following will analyze how to choose the right material from several aspects.view What Is a Heat Sink? 7 Tips for Choosing the Right Heat SinkSeptember 5, 2023Because of the increasing need for high-performance electronics, advanced devices with fast microprocessors and high transistor densities are being manufactured. This technical modification in such el...view

What Is a Heat Sink? 7 Tips for Choosing the Right Heat SinkSeptember 5, 2023Because of the increasing need for high-performance electronics, advanced devices with fast microprocessors and high transistor densities are being manufactured. This technical modification in such el...view Unlocking Precision: Exploring the Parts of a CNC MachineSeptember 22, 2023Are you ready to dive into the world of CNC (Computer Numerical Control) machines? If you're fascinated by precision engineering and the wonders it can achieve, you've come to the right place.view

Unlocking Precision: Exploring the Parts of a CNC MachineSeptember 22, 2023Are you ready to dive into the world of CNC (Computer Numerical Control) machines? If you're fascinated by precision engineering and the wonders it can achieve, you've come to the right place.view

EN

EN

ru

ru