Welcome to the world of precision engineering, where the subtle details can make a world of difference. In the realm of CNC machining and automotive components, 'Machined Rotors' emerge as a pivotal player, quietly ensuring your safety and vehicle performance. In this comprehensive guide, I, as a specialist in CNC machining services at Richconn, will walk you through the intricacies of Machined Rotors. Together, we'll delve into their fundamental aspects, manufacturing processes, comparisons with other braking components, various types, choosing the right fit, maintenance, and how Richconn's expertise can serve your Machined Rotors needs.

Let's begin our journey by grasping the fundamental concept of Machined Rotors. These critical components play an indispensable role in your vehicle's braking system, providing the stopping power needed for safe driving. Machined Rotors, often referred to as brake rotors or discs, are precision-engineered circular discs that rotate with your vehicle's wheels. When you press the brake pedal, brake pads are clamped onto the Machined Rotors, generating friction that slows down and eventually stops your vehicle.

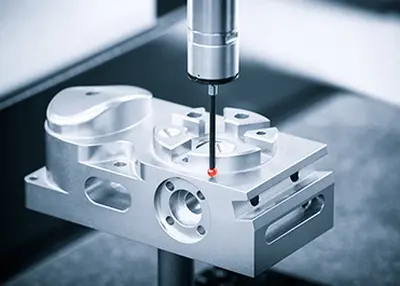

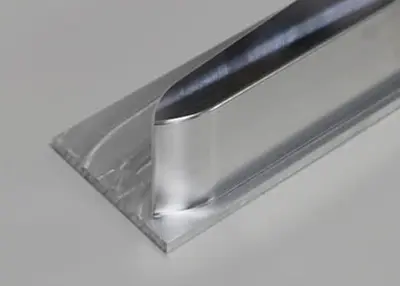

The art of crafting Machined Rotors is a testament to precision engineering. These components are typically made from high-quality cast iron or composite materials. The manufacturing process involves cutting, shaping, and finishing the raw material to meet strict tolerances and quality standards. At Richconn, we utilize state-of-the-art CNC machining technology to ensure the utmost precision and consistency in every Machined Rotor we produce.

Table 1: Machined Rotors Manufacturing Process

| Process Stage | Description |

|---|---|

| Raw Material Selection | Choose high-quality cast iron or composite materials. |

| Cutting and Shaping | Use CNC machinery to cut and shape the material into rotor blanks. |

| Precision Machining | Employ CNC machining for detailed rotor profiling, drilling, or slotting. |

| Heat Treatment | Subject rotors to heat treatment for enhanced durability and resistance to cracking. |

| Surface Finish | Apply finishing processes for optimal rotor smoothness and longevity. |

| Quality Control | Rigorous quality checks ensure each rotor meets specified standards. |

To appreciate Machined Rotors fully, it's crucial to compare them to other braking components. While there are alternatives like slotted and drilled rotors, understanding the distinctions is paramount. Machined Rotors offer the advantage of even wear, improved heat dissipation, and enhanced performance, making them an excellent choice for most vehicles. These advantages make them a top choice for high-performance and safety-conscious drivers.

Table 2: Machined Rotors vs. Other Braking Components

| Braking Component | Advantages of Machined Rotors | Use Cases |

|---|---|---|

| Machined Rotors | Even wear, excellent heat dissipation, enhanced performance | Ideal for daily drivers, high-performance vehicles |

| Slotted Rotors | Improved bite, reduced brake fade | Performance and racing applications |

| Drilled Rotors | Effective heat dissipation, weight reduction | Sport and high-performance vehicles |

| Drilled & Slotted Rotors | Combined advantages of drilled and slotted rotors | Balanced performance for various applications |

In the table above, we've summarized the advantages of Machined Rotors compared to other braking components and provided insights into their best use cases.

Machined Rotors come in various types, each catering to specific driving needs. These types include slotted, drilled, slotted, and drilled & slotted Machined Rotors. Your choice should align with your driving style, vehicle type, and performance expectations. For instance, drilled Machined Rotors are excellent for heat dissipation, making them a favorite among performance enthusiasts.

Table 3: Types of Machined Rotors and Their Characteristics

| Machined Rotor Type | Characteristics | Best Applications |

|---|---|---|

| Slotted Machined Rotors | Slots provide improved bite, reduce brake fade | Performance and racing applications |

| Drilled Machined Rotors | Holes enhance heat dissipation, reduce weight | Sport and high-performance vehicles |

| Slotted & Drilled Machined Rotors | Combined benefits of slots and holes | Balanced performance for various applications |

These tables offer a quick reference guide to assist you in selecting the most suitable Machined Rotors for your specific requirements. Your choice depends on your driving style, vehicle type, and performance expectations.

Choosing the right Machined Rotors for your vehicle is a crucial decision. Your selection will impact not only your vehicle's braking performance but also your safety on the road. Let's explore the factors and considerations that will help you make an informed choice.

The type of vehicle you drive plays a significant role in your Machined Rotors selection. Different vehicles have varying braking needs, and it's essential to choose rotors that align with your vehicle type. Here are some general recommendations:

Passenger Cars: For everyday use, standard Machined Rotors are a suitable choice. They offer reliable braking performance for typical commuting and errands.

Sports Cars: If you drive a sports car, consider high-performance Machined Rotors designed to handle more aggressive braking requirements. Drilled or slotted rotors may also be a good fit.

Trucks and SUVs: These vehicles are heavier and may require rotors with enhanced heat dissipation capabilities. Drilled or slotted rotors can be beneficial for improved braking under load.

Your typical driving conditions should influence your Machined Rotors selection. Consider whether you predominantly drive in city traffic, on the highway, or in more challenging conditions.

City Driving: Standard Machined Rotors are typically sufficient for city driving, offering dependable braking for stop-and-go traffic.

Highway Driving: For highway driving, Machined Rotors with improved heat dissipation, such as slotted or drilled rotors, can enhance brake performance during extended periods of use.

Performance Driving: If you enjoy spirited or high-performance driving, opt for rotors designed to handle the additional heat generated during aggressive braking maneuvers.

Your personal performance expectations and driving style play a critical role in choosing the right Machined Rotors. Here are some factors to consider:

Brake Feel: Do you prefer a firmer brake pedal feel? If so, consider slotted or drilled rotors, as they can provide better bite and responsiveness.

Heat Management: If you anticipate generating significant heat during your drives, such as in racing or performance applications, drilled or slotted Machined Rotors can help dissipate heat more effectively.

Durability: Consider how long you plan to keep your vehicle and whether you're willing to invest in long-lasting, high-quality Machined Rotors that may be more expensive upfront but offer extended longevity.

If you're uncertain about the best Machined Rotors for your vehicle, it's advisable to consult with experts in the field. They can assess your specific needs, vehicle characteristics, and driving habits to provide tailored recommendations.

At Richconn, we understand the importance of selecting the right Machined Rotors for your vehicle. Our team of experts can provide personalized guidance and recommendations based on your unique requirements. We offer a wide range of Machined Rotors, including slotted, drilled, and slotted & drilled types, ensuring that we have the perfect fit for your vehicle and driving style. Contact us today to discuss how we can enhance your vehicle's safety and performance.

By carefully considering these factors, you can make an informed decision when choosing Machined Rotors that are ideal for your vehicle and driving habits. Remember that the right choice leads to improved braking performance and safety on the road.

Proper maintenance of Machined Rotors is essential to ensure their longevity, optimal performance, and, most importantly, your safety on the road. Let's delve into the details of how you can effectively maintain your Machined Rotors.

Regular inspections of your Machined Rotors are the first step in ensuring they are in good condition. Here's what to look for:

Thickness: Measure the rotor's thickness to ensure it is within the manufacturer's specified minimum thickness. If it's below this limit, it's time to replace the rotors.

Visible Damage: Check for any visible signs of damage, such as cracks, grooves, or warping. Damaged rotors can affect braking performance and safety.

Rust and Corrosion: Surface rust is common on rotors, especially if your vehicle sits for an extended period. However, excessive rust or corrosion should be addressed.

Regular cleaning of your Machined Rotors can help remove brake dust, debris, and contaminants that can affect their performance. Here's a simple cleaning process:

Materials Needed: Brake cleaner, a wire brush, lint-free cloth, and safety goggles.

Steps:

Elevate the vehicle using a jack and securely support it with jack stands.

Remove the wheel to access the rotor.

Spray brake cleaner onto the rotor surface to remove dust and contaminants.

Use a wire brush to gently scrub the rotor's surface.

Wipe the rotor with a lint-free cloth to ensure it's clean and dry.

Proper maintenance of Machined Rotors involves monitoring and replacing brake pads as needed. When your brake pads wear down to a certain thickness, it's essential to replace them to prevent damage to the rotors. Regularly inspect your brake pads and replace them if they are too thin.

Brake fluid is a crucial component of your vehicle's braking system. Regularly check the level and condition of your brake fluid. If it appears discolored or contaminated, it's time to have it changed. Maintaining clean brake fluid helps prevent corrosion and ensures the brake system's effectiveness.

While you can perform some basic maintenance tasks, it's vital to have your Machined Rotors and braking system professionally inspected and serviced. A professional mechanic can provide a thorough assessment, identify potential issues, and ensure your brakes are in optimal working condition. They can also address any issues with rotor warping or uneven wear.

At Richconn, we understand the significance of Machined Rotors' maintenance. Our team of experts can provide guidance on proper maintenance practices and assist with any rotor-related issues. We are committed to ensuring that your Machined Rotors deliver optimal performance and safety throughout their lifespan.

Regular maintenance is not only a matter of safety but also a way to extend the life of your Machined Rotors and reduce the overall cost of vehicle ownership. By following these maintenance practices, you can enjoy reliable braking performance and peace of mind on the road.

As a specialist precision machine shop, Richconn is committed to delivering top-quality Machined Rotors to meet the specific needs of our clients. Our expertise in precision engineering and CNC machining sets us apart as a reliable partner in the automotive industry.

At Richconn, we understand the critical role precision plays in the manufacturing of Machined Rotors. Our CNC machining capabilities ensure that each rotor is crafted with the utmost precision, adhering to strict tolerances and quality standards. This precision leads to consistent and reliable performance, contributing to your vehicle's safety and efficiency.

We offer a wide range of Machined Rotors to cater to various vehicle types and driving needs. Whether you drive a daily commuter, a high-performance sports car, or a heavy-duty truck, we have the right solution for you. Our customization options include slotted, drilled, and slotted & drilled Machined Rotors, allowing you to select the ideal fit for your requirements.

Quality is our top priority at Richconn. Each Machined Rotor undergoes rigorous quality control checks to ensure that it meets the specified standards. Our commitment to quality extends to the materials we use, the manufacturing process, and the final product. You can trust that when you choose Richconn, you're choosing Machined Rotors of the highest quality.

Our team of experts is always ready to assist you in making the right choice when it comes to Machined Rotors. Whether you have questions about the best type of rotor for your vehicle or need guidance on maintenance, our specialists can provide the information and support you need.

If you're looking for high-quality Machined Rotors or require CNC machining services, don't hesitate to contact us. We are committed to serving your automotive needs, enhancing your vehicle's performance and safety. Reach out to Richconn, and let us be your trusted partner in precision engineering.

In conclusion, Machined Rotors play a pivotal role in ensuring your vehicle's safety and performance. Choosing the right type of rotor, maintaining them properly, and working with a reliable CNC machining service provider like Richconn can make a significant difference in your driving experience. Trust in precision engineering and make informed decisions to enjoy optimal braking performance and peace of mind on the road.

Manufacturing Process and Selection Guide for CNC Processing iPhone CasesNovember 14, 2023In a world where Precision Machining innovation, Richconn stands as a pioneer in CNC machining technology, redefining the landscape of iPhone protection. Dive into the intricacies of CNC machining for iPhone cases and discover a realm where design meets durability, guided by a commitment to excellence.view

Manufacturing Process and Selection Guide for CNC Processing iPhone CasesNovember 14, 2023In a world where Precision Machining innovation, Richconn stands as a pioneer in CNC machining technology, redefining the landscape of iPhone protection. Dive into the intricacies of CNC machining for iPhone cases and discover a realm where design meets durability, guided by a commitment to excellence.view Anodized Aluminum: How Much Do You Know?April 4, 2023Anodized aluminum refers to a layer of dense aluminum oxide plated on the surface of aluminum and aluminum alloy in order to prevent further oxidation, with chemical properties that are the same as th...view

Anodized Aluminum: How Much Do You Know?April 4, 2023Anodized aluminum refers to a layer of dense aluminum oxide plated on the surface of aluminum and aluminum alloy in order to prevent further oxidation, with chemical properties that are the same as th...view What is Precision Machining: Process, Applications & BenefitsAugust 24, 2023Nowadays, the prowess of precision machining lies in the unfaltering delivery of unparalleled quality, precision, and intricacy, which reverberates across a spectrum of industries. With advanced techn...view

What is Precision Machining: Process, Applications & BenefitsAugust 24, 2023Nowadays, the prowess of precision machining lies in the unfaltering delivery of unparalleled quality, precision, and intricacy, which reverberates across a spectrum of industries. With advanced techn...view Basic Parts of CNC Lathe and Their MaintenanceOctober 20, 2023CNC lathes and steering centers are highly accurate and efficient automatic machine tools. The machine is equipped with a multi-station turret or power turret for a wide range of machining capabilities. It can handle linear cylinders, tilting cylinders, arcs and a variety of complex workpieces such as threads, grooves, worms, etc.view

Basic Parts of CNC Lathe and Their MaintenanceOctober 20, 2023CNC lathes and steering centers are highly accurate and efficient automatic machine tools. The machine is equipped with a multi-station turret or power turret for a wide range of machining capabilities. It can handle linear cylinders, tilting cylinders, arcs and a variety of complex workpieces such as threads, grooves, worms, etc.view What are the requirements for a machining plant that produces medical parts?October 31, 2023The machining and manufacturing of medical CNC equipment parts is different from the machining of ordinary common parts, the medical field has its own special characteristics of use, so it needs to ha...view

What are the requirements for a machining plant that produces medical parts?October 31, 2023The machining and manufacturing of medical CNC equipment parts is different from the machining of ordinary common parts, the medical field has its own special characteristics of use, so it needs to ha...view What Is Galvanized Sheet Metal? The Complete Basics to Get StartedOctober 12, 2023Galvanized sheet metal is one of the most cost-effective and popular types of metal in the market. Here are the complete basics about it for you to get started.view

What Is Galvanized Sheet Metal? The Complete Basics to Get StartedOctober 12, 2023Galvanized sheet metal is one of the most cost-effective and popular types of metal in the market. Here are the complete basics about it for you to get started.view