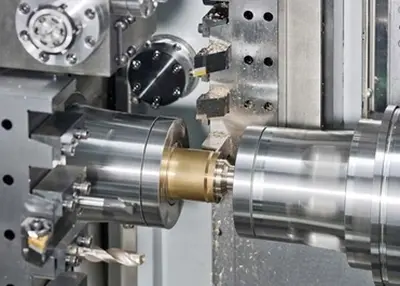

In the intricate tapestry of CNC milling materials, the careful selection of materials emerges as the linchpin, dictating the success and precision of every project. From the robust realm of metals to the versatile landscape of plastics and the innovative realm of composites, each material brings its unique attributes to the CNC milling table. This expansive exploration aims to delve deeper into the diverse array of materials, shedding light on their distinct characteristics and the roles they play in the world of CNC milling.

Metals, the stalwarts of CNC milling, exemplify durability and precision. Aluminium, steel, brass, and copper, among others, are not merely materials but conduits for achieving intricate precision. Each metal type bears its distinct properties, be it the conductivity of copper or the resilience of steel. The choice of metals extends beyond their durability; it is a strategic decision for applications demanding high tolerance, structural integrity, and meticulous precision.

Metals are often chosen for their strength, making them ideal for applications that require high tolerance and precision. The durability and resilience of metals ensure that CNC-machined components can withstand demanding conditions, contributing to the longevity of the final product.

Plastics, with their remarkable versatility, have carved a significant niche in CNC milling materials. From the clarity of acrylic to the resilience of nylon, plastics offer a myriad of options. Their lightweight nature, coupled with ease of machinability, makes them a go-to choice for diverse applications. The ability to mold them into intricate shapes, cost-effectiveness, and adaptability render plastics indispensable for rapid prototyping, low-volume production, and projects where complexity meets efficiency.

Plastics bring a level of versatility that extends beyond their mechanical properties. They are chosen not only for their ease of machining but also for their electrical insulation properties, corrosion resistance, and suitability for industries where weight is a critical factor.

Composites, a symphony of materials harmoniously combined, exemplify the epitome of strength and innovation. Whether it's the robust carbon fiber, the versatile fiberglass, or the protective Kevlar, composites offer a high-strength-to-weight ratio. Ideal for applications where lightweight yet durable materials are paramount, composites take center stage. Their superior strength, stiffness, and resistance to impact make them the materials of choice for aerospace, automotive, and high-performance industries.

The innovative nature of composites lies in their ability to combine different materials, harnessing the strengths of each. This versatility allows for tailoring materials to specific project requirements, providing solutions that balance strength, weight, and durability.

Wood, with its timeless elegance, continues to be a captivating choice in CNC milling materials. Hardwoods such as oak and maple and softwoods like pine and cedar bring a natural warmth and aesthetic appeal. Beyond its visual allure, wood's machinability and adaptability to CNC precision make it an evergreen choice for crafting bespoke furniture, intricate cabinetry, and artistic embellishments. The marriage of CNC precision and the organic beauty of wood results in creations that seamlessly blend craftsmanship and technology.

Wood, often associated with traditional craftsmanship, finds a new dimension in CNC milling. The precision offered by CNC machines allows for intricate detailing and complex designs, expanding the possibilities for wooden components in various industries.

In summary, the realm of CNC milling materials is a vast and dynamic landscape, offering an array of options to cater to the multifaceted needs of diverse projects. Whether the pursuit is for unwavering strength, intricate precision, cost-effectiveness, or the timeless allure of natural beauty, there exists a material perfectly suited to the task. From the precision of metals to the adaptability of plastics, the innovation of composites, and the timeless elegance of wood, the CNC milling journey is an exploration of possibilities where material selection becomes an art, sculpting ideas into tangible reality. The next CNC milling endeavor beckons with a world of materials waiting to be harnessed for innovative and precise creations.

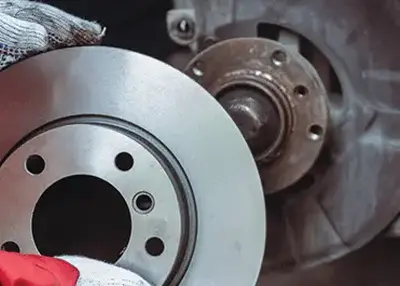

What Are Machined Rotors?November 8, 2023Welcome to the world of precision engineering, where the subtle details can make a world of difference. In the realm of CNC machining and automotive components, 'Machined Rotors' emerge as a pivotal player, quietly ensuring your safety and vehicle performance.view

What Are Machined Rotors?November 8, 2023Welcome to the world of precision engineering, where the subtle details can make a world of difference. In the realm of CNC machining and automotive components, 'Machined Rotors' emerge as a pivotal player, quietly ensuring your safety and vehicle performance.view Manufacturing Process and Selection Guide for CNC Processing iPhone CasesNovember 14, 2023In a world where Precision Machining innovation, Richconn stands as a pioneer in CNC machining technology, redefining the landscape of iPhone protection. Dive into the intricacies of CNC machining for iPhone cases and discover a realm where design meets durability, guided by a commitment to excellence.view

Manufacturing Process and Selection Guide for CNC Processing iPhone CasesNovember 14, 2023In a world where Precision Machining innovation, Richconn stands as a pioneer in CNC machining technology, redefining the landscape of iPhone protection. Dive into the intricacies of CNC machining for iPhone cases and discover a realm where design meets durability, guided by a commitment to excellence.view What Is 3-axis, 4-axis, and 5-axis CNC Machining?April 4, 2023CNC machining has become one of the most critical manufacturing processes used in workshops globally. By adding computer control to previous manual processes, the accuracy and precision of machining p...view

What Is 3-axis, 4-axis, and 5-axis CNC Machining?April 4, 2023CNC machining has become one of the most critical manufacturing processes used in workshops globally. By adding computer control to previous manual processes, the accuracy and precision of machining p...view Galvanneal vs Galvanized: Which Sheet Metal Material Is Right for Your Manufacturing Needs?March 22, 2024Galvannealed and galvanized steel are distinct types of sheet metal, produced through different processes and possessing unique properties. Read on to find out more!view

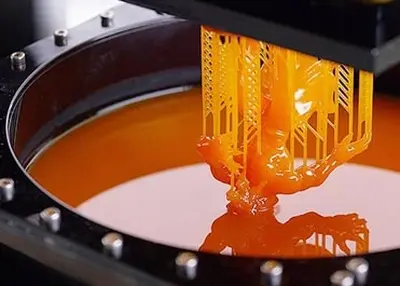

Galvanneal vs Galvanized: Which Sheet Metal Material Is Right for Your Manufacturing Needs?March 22, 2024Galvannealed and galvanized steel are distinct types of sheet metal, produced through different processes and possessing unique properties. Read on to find out more!view Types of 3D Printers: a Guide to 2023October 9, 20233D printing technology has evolved tremendously over the past few decades and has seen the emergence of a variety of different types of 3D printers. These different types of 3D printers differ in term...view

Types of 3D Printers: a Guide to 2023October 9, 20233D printing technology has evolved tremendously over the past few decades and has seen the emergence of a variety of different types of 3D printers. These different types of 3D printers differ in term...view What Will Determine the Precision of CNC Machining?August 10, 2022In the preparation of CNC machining programs, proper use of methods and techniques is of great significance to ensure and improve the machining accuracy of CNC machine tools. So what determines the ma...view

What Will Determine the Precision of CNC Machining?August 10, 2022In the preparation of CNC machining programs, proper use of methods and techniques is of great significance to ensure and improve the machining accuracy of CNC machine tools. So what determines the ma...view

EN

EN

ru

ru