Titanium is a silver-white metal appreciated for its exceptional strength, lightweight nature, and corrosion resistance. These valuable properties have made titanium a sought-after material in various industries, notably aerospace, automotive, medical, and chemical processing. Titanium is available in multiple grades and alloys, each with distinct properties tailored for specific uses. To help you avoid this, this article will act as a titanium guide as it introduces titanium material including describing its properties, discussing titanium and titanium in different grades and applications, and how to select the right grade.

is titanium an alloy? No, titanium, a metal with the atomic number 22 and a silvery-white appearance is known for its lightweight, ductile, strong, corrosion-resistant, and biocompatible properties, boasting a high strength-to-weight ratio. This element ranks as the 9th most abundant on Earth, commonly found in rocks, clay, and sand. The primary commercial minerals used for titanium extraction and refinement are rutile and ilmenite. Titanium is categorized into alpha-alloys, beta-alloys, and alpha-beta alloys. Alpha alloys comprise oxygen as the main alloying element and are often combined with metals like aluminum, molybdenum, and vanadium to enhance strength, and corrosion resistance, and reduce weight. Applications of titanium and its alloys span various industries, including commercial and aerospace sectors, power plant condensers, desalination plants, marine environments, architectural structures, medical implants like joint replacements, and consumer products such as golf clubs and bicycle frames.

Titanium material has unique properties making it suitable for a variety of uses. Below are the physical properties and chemical properties of titanium material and its alloys that make them suitable for rapid prototyping.

Rapid prototyping in manufacturing involves many processes such as CNC machining, 3D printing, and injection molding. Of the many materials suitable for rapid prototyping, titanium material is a popular one due to its unique properties. But do you know any titanium properties? For example, is titanium heavy, or is titanium light? How strong is titanium? Some common properties of titanium are shown to you as below:

Density of Titanium

Is titanium malleable? Commercially pure titanium is 99% pure and has a tensile strength of 434 MPa or 63,000 psi, a titanium strength that is equal to low-grade steel alloys. It can be used as a replacement for steel and is 45% lighter than steel, twice as strong as aluminum, and 60% denser than aluminum. When mixed with other metals, the alloys can reach a tensile density titanium of more than 1400 MPa or 200,000 psi.

Weight of Titanium

How heavy is titanium? Titanium is a light metal with a density of about 4540 kg/m³, compared to steel’s density of 7900 kg/m³ and aluminum at 2710 kg/m³.

Refractory

Titanium density is 4.5 g/cm³ with a melting point of more than 3000°F (1650°C) and boiling point of 5948°F (3287°C). Its high melting and boiling points make it a very useful metal in terms of refractory properties.

The chemical properties of titanium are similar to those of zirconium and silica, which are part of group 4 (IVB) in the middle of the periodic table. Group 4 elements exhibit characteristics between metals and nonmetals. Titanium, like aluminum and magnesium, oxidizes upon exposure to air, forming a protective oxide layer that prevents further oxidation when interacting with oxygen and water. Below are the properties of titanium:

Anti-Corrosion and Anti-rust

Does titanium corrode? Will titanium rust? Titanium’s oxide layer provides excellent protection against corrosive elements, which is almost as effective as platinum. The oxide layer makes titanium resistant to stronger elements, such as sulfuric acid, moist chlorine gas, chloride solutions, hydrochloric acid, and most organic acids. However, it can be corroded when exposed to concentrated acids.

Reactivity

In terms of thermodynamics, titanium ignites in the air at temperatures below its melting point. The melting process of titanium occurs in a chemically inert environment like a vacuum. Due to its reactivity at high temperatures, titanium does not typically melt under normal conditions, as it can combust in the presence of oxygen. Titanium reacts with chlorine at 550°C and combines with other halogen gases although it absorbs hydrogen.

Thermal Expansion

Titanium and its alloys exhibit lower thermal expansion compared to aluminum, ferrous, nickel, and copper alloys. This reduced thermal expansion coefficient contributes to their improved compatibility with materials like ceramics and glass, while also reducing warping and fatigue effects.

After reading about titanium prosperities, you've concluded that titanium is the ideal metal for your upcoming product. However, this is only the initial phase. Several crucial decisions remain to be made. With various grades of commercially pure titanium and titanium alloys available, it's essential to select the appropriate forms and grades to guarantee the successful completion of your project. Below is a list of commercially pure titanium and many of the most common alloys.

Grade 1 Titanium

Grade 1 titanium is known for its exceptional malleability, making it highly suitable for various shaping processes. Its notable ductility ensures flexibility while also maintaining the required level of impact resistance. This particular grade is commonly applied in the manufacturing of plates, tubing, piping, and a diverse range of other products where superior weldability and formability are crucial considerations.

Table 1: Grade 1 Titanium | |

Applications | Aerospace, Medical, Manufacturing, Automotive parts, Chemical processing facilities, Architecture, power, Airplane structures and frames, Desalination |

Forms Available | Bar, Flanges, Forgings, Sheet, Welding Wire |

Grade 2 Titanium

Grade 2 titanium offers a slightly increased strength compared to Grade 1 titanium, while still retaining excellent malleability. It boasts higher tensile strength levels, yet remains highly moldable. It is widely accessible, making it a more cost-effective option in comparison to alternative grades. Available in various product forms, including bar, billet, plate, and wire, Grade 2 titanium is a versatile choice for a range of applications.

Table 2: Grade 2 Titanium | |

Applications | Power generation, Hydro-carbon processing, Exhaust pipe shrouds, Airframe skin |

Forms Available | Bar, Fittings, Flanges, Forgings, Pipe, Plate, Sheet, Tube, Welding Wire, Wire |

Grade 3 Titanium

Although Grade 3 titanium is less commonly utilized compared to Grade 2, it serves specific purposes due to its unique properties. With higher strength levels than Grades 1 and 2, Grade 3 titanium offers excellent weldability and remarkably high corrosion resistance. While it may be less malleable than the other two grades, its enhanced strength and resistance qualities make it a favorable option for certain applications.

Table 3: Grade 3 Titanium | |

Applications | Chemical processing, Marine applications, Aerospace |

Forms Available | Bar, Fittings, Flanges, Forgings, Pipe, Plate, Sheet, Tube, Welding Wire, Wire |

Grade 4 Titanium

Grade 4 titanium stands out as the most robust among pure grade titanium options, although it exhibits lower malleability. Despite being less moldable, it offers excellent cold formability. Its exceptional strength, durability, and weldability position Grade 4 titanium as a preferred choice for numerous medical and industrial applications.

Table 4: Grade 4 Titanium | |

Applications | Surgical hardware, Heat exchangers, CIP equipment |

Forms Available | Bar, Fittings, Flanges, Forgings, Pipe, Plate, Sheet, Tube, Welding Wire, Wire |

Grade 5 Titanium (Ti 6Al-4V)

Ti 6AI-4V, also known as grade 5 titanium alloy, is widely recognized as the predominant titanium alloy and is commonly hailed as the mainstay of the aerospace sector for valid reasons. This alloy demonstrates exceptional qualities, withstanding temperatures of up to 600 degrees Fahrenheit, boasting robust strength, lightweight properties, superior formability, and outstanding corrosion resistance. Comprised of a blend of titanium, aluminum, vanadium, and iron, Ti 6AI-4V alloy is renowned for its versatile applications in various industries, especially aerospace.

Table 5: Grade 5 Titanium (Ti 6Al-4V) | |

Applications | Aerospace, Chemical Processing, Marine, Medical |

Forms Available | Bar, Billet, Foil, Sheet, Seamless pipe, Wire, Plate |

Grade 7 Titanium Alloy

Grade 7 titanium alloy is renowned for its exceptional corrosion resistance, making it the most resistant among titanium alloys. While it shares many properties with Grade 2 pure titanium, the inclusion of palladium enhances its weldability and formability. Primarily utilized in chemical production equipment, Grade 7 titanium alloy is readily available in various product forms to cater to diverse industrial needs.

Table 6: Grade 7 Titanium Alloy | |

Applications | Chemical Processing, Desalination, Power generation |

Forms Available | Bar, Fittings, Flanges, Forgings, Pipe, Plate, Sheet, Tube, Welding Wire, Wire |

Titanium Grade 12 (Ti-0.3-Mo-0.8Ni)

Grade 12 titanium exhibits strength comparable to that of the 300 series steels and boasts exceptional formability and weldability, rendering it a favorable selection for a wide range of fabricated applications. Its notable corrosion resistance further enhances its suitability, making it a popular choice for various industrial applications.

Table 7: Titanium Grade 12 (Ti-0.3-Mo-0.8Ni) | |

Applications | Chemical processing, Desalination, Power generation, Industrial |

Forms Available | Tube |

Grade 23 Titanium (Ti 6AL-4V ELI)

Ti 6AL-4V ELI, known as Grade 23 titanium, is frequently manufactured into coils, strands, wires, or flat wires. Comprising titanium, vanadium, and aluminum, this alloy boasts exceptionally high tensile and yield strength, albeit at the cost of reduced ductility and weldability. Its distinct biocompatibility quality has propelled its popularity in a wide array of medical and dental applications.

Table 8: Grade 23 Titanium (Ti 6AL-4V ELI) | |

Applications | Aerospace, Chemical Processing, Marine, Medical |

Forms Available | Bar, Forgings, Plate, Sheet, Welding Wire, Wire |

Titanium (10V-2Fe-3Al)

Titanium 10V-2Fe-3Al belongs to the Titanium Beta Alloy category, known for its superior hardness and strength compared to many other titanium alloys. This heat-treatable alloy is weldable and easily formed, but being a Beta Alloy, it is more challenging to machine than most titanium alloys. Common machining issues include flank wear, spring-back, and chip control. To address these challenges, utilizing positive rake chip grooves and light hones on the cutting edge is recommended.

Table 9: Titanium (10V-2Fe-3Al) | |

Applications | Airframe Components, Compressor Blades, Disks, Wheels and Spacers |

Forms Available | Bar, Forgings, Plate, Sheet, Seamless Pipe, Seamless Tube, Welded Pipe, Welded Tube, Wire |

Selecting the appropriate titanium grade involves comprehending the distinct properties of various titanium grades and their impact on the project. Here are some key factors to keep in mind when selecting the correct titanium grade for rapid prototyping.

1. Chemical Composition

The chemical makeup of titanium differs based on the grade, exerting a significant impact on its properties and attributes. Titanium alloys are created by blending titanium with various elements like aluminum, vanadium, molybdenum, nickel, and others. These alloy mixtures are meticulously selected to improve specific characteristics such as strength, resistance to corrosion, ability to withstand high temperatures, and more. Grasping the complex chemical composition of titanium is essential for assessing its performance and suitability across diverse applications. By taking into account these aspects, including the proportions of alloying components and their influence on the final material, you can make well-informed decisions to ensure the optimal utilization of titanium in your specific use case.

2. Strength and Elasticity

The strength and elasticity of titanium alloys can vary widely depending on the particular grade and composition of the alloy. Factors such as tensile strength, yield strength, and modulus of elasticity are crucial in assessing the strength of titanium and its ability to bounce back after deformation. Selecting a titanium grade that finds the right equilibrium between strength and elasticity is vital in achieving peak performance, longevity, and durability that align with your particular needs.

3. Corrosion Resistance

One of titanium's most notable benefits is its exceptional corrosion resistance, making it highly suitable for a range of applications in corrosive settings. However, it's important to acknowledge that different titanium grades offer varying degrees of corrosion resistance, influenced by their distinct chemical composition and surface treatments. Therefore, when picking a titanium grade, it's essential to thoughtfully consider the corrosive environment, such as exposure to acids, alkalis, or saltwater, and the specific level of resistance needed for your planned use. By selecting the right grade and surface treatment, you can ensure optimal performance, durability, and dependability of your titanium product, even in challenging and harsh conditions.

4. Machinability

The machinability of a titanium grade is a critical aspect to consider. Pure titanium grades, although renowned for their corrosion resistance, lack mechanical properties like ductility and malleability, resulting in lower machinability. In contrast, titanium grade 5 is known to be the most easily machinable among titanium grades.

5. Cost

The titanium cost can vary significantly depending on the grade, availability, and market factors. Higher grades of titanium, such as Grade 4, are often more expensive due to their superior mechanical properties, corrosion resistance, and wider range of applications. Additionally, the scarcity of certain grades, like Grade 7, due to limited production or specific demand, can contribute to their higher price. When selecting the grade of titanium for your project, it is important to consider the cost relative to the specific advantages and properties offered by each grade. How much does titanium cost? This includes factors such as strength, weight, heat resistance, compatibility with other materials, and overall performance and longevity of your application. By carefully evaluating these aspects and considering the long-term benefits, you can make an informed decision that balances cost-effectiveness with the desired performance requirements for your project.

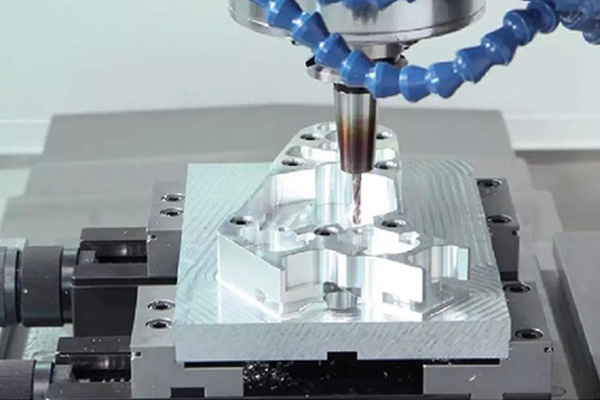

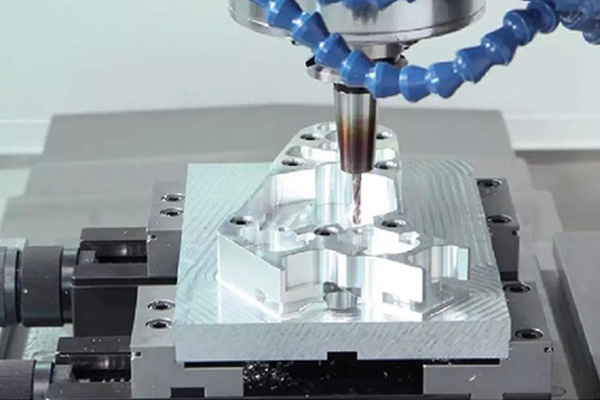

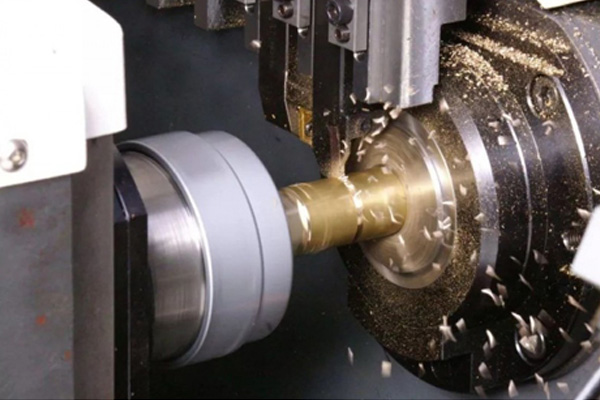

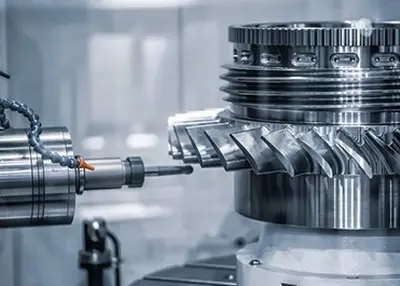

The process of rapid prototyping encompasses various techniques to quickly produce products, utilizing a range of materials, with titanium standing out for its exceptional properties like strength and lightweight. There are many machining and fabrication methods you can use with titanium; there are a few titanium prototyping methods you can try, like CNC milling or CNC turning. If you are not familiar with this, you can find the best rapid prototyping service provider.

Richconn is sure of its craft having gained years’ worth of experience working with many materials, of which titanium is the tip of the iceberg. For the best rapid prototyping process using titanium, or if you have another material in mind, feel free to contact Richconn, and professional suggestions will be given to you.

Yes, titanium and its alloys can be machined as they possess favorable mechanical properties and are workable materials. Nevertheless, CNC machining of titanium should be overseen by skilled professionals to ensure precise and efficient outcomes.

While it can be easy to machine, properties such as low young modulus, extreme hardness, and low ductility make titanium hard to machine. However, the alloys have an improved mechanical properties. Consequently, they are easier to machine than the pure grade. CNC machining titanium, therefore, comes with understanding the grades you are working with and its properties.

Titanium performs well in humid environments and seawater, offering superior corrosion resistance compared to stainless steel. They exhibit exceptional resistance to pitting corrosion, acid corrosion, and stress corrosion, particularly standing out for their abilities to withstand alkali, chloride, chlorine, nitric acid, and sulfuric acid environments.

The article introduced titanium, detailing its characteristics and applications. For further information on titanium, feel free to reach out to a Richconn representative. Richconn offers diverse manufacturing capabilities and additional value-added services to meet your prototyping and production requirements. For more details or to request a complimentary quote, click the banner to visit its website>>

Machinist Tools: What They Are, How to Use ThemDecember 1, 2023Machinist tools are a variety of products that are used to shape, cut, grind, shear, and form metal into a desired part. They are essential for metalworking and machining, which are the processes of creating metal products or components by removing metal chips in the workpiece.view

Machinist Tools: What They Are, How to Use ThemDecember 1, 2023Machinist tools are a variety of products that are used to shape, cut, grind, shear, and form metal into a desired part. They are essential for metalworking and machining, which are the processes of creating metal products or components by removing metal chips in the workpiece.view What Are the Categories of Fastener Nuts?October 30, 2023Some parts manufactured in the automotive industry can only function if they are connected to other parts during the assembly process. As a result, automotive parts manufacturing relies on designs that have high tolerances and incorporate connecting mechanism features, of which fasteners are very common.view

What Are the Categories of Fastener Nuts?October 30, 2023Some parts manufactured in the automotive industry can only function if they are connected to other parts during the assembly process. As a result, automotive parts manufacturing relies on designs that have high tolerances and incorporate connecting mechanism features, of which fasteners are very common.view CNC POR: Demystifying the Key Technology in CNC MachiningNovember 2, 2023In the world of precision engineering and manufacturing, CNC technology plays a pivotal role. Among the various CNC techniques, CNC POR stands out as a critical component, offering unmatched precision, efficiency, and versatility.view

CNC POR: Demystifying the Key Technology in CNC MachiningNovember 2, 2023In the world of precision engineering and manufacturing, CNC technology plays a pivotal role. Among the various CNC techniques, CNC POR stands out as a critical component, offering unmatched precision, efficiency, and versatility.view Common Impact Resistant Plastics.October 17, 2023Tough. Unbreakable. Resistant to punctures and cracks from impact. That's how some people describe impact-resistant plastic. However, as you will see, this term is ambiguous. Just because a piece of chewing gum doesn't break in half when you hit it with a hammer doesn't mean it's impact resistant. Put the same gum in the freezer for a while and then hit it. Only splinters.view

Common Impact Resistant Plastics.October 17, 2023Tough. Unbreakable. Resistant to punctures and cracks from impact. That's how some people describe impact-resistant plastic. However, as you will see, this term is ambiguous. Just because a piece of chewing gum doesn't break in half when you hit it with a hammer doesn't mean it's impact resistant. Put the same gum in the freezer for a while and then hit it. Only splinters.view Machining Commonly Used 24 Kinds of MaterialsOctober 23, 2023Can be used for CNC machining, mold processing of more than a hundred kinds of materials, metal, plastic, but according to the actual needs of different, each material use as well as the demand varies, the most commonly used 24 kinds of materials.view

Machining Commonly Used 24 Kinds of MaterialsOctober 23, 2023Can be used for CNC machining, mold processing of more than a hundred kinds of materials, metal, plastic, but according to the actual needs of different, each material use as well as the demand varies, the most commonly used 24 kinds of materials.view Machined Castings - Your Comprehensive GuideNovember 7, 2023Are you looking to delve into the fascinating world of machined castings? Are you curious about how these essential components are made, their diverse applications, and the key factors to consider when choosing a supplier?view

Machined Castings - Your Comprehensive GuideNovember 7, 2023Are you looking to delve into the fascinating world of machined castings? Are you curious about how these essential components are made, their diverse applications, and the key factors to consider when choosing a supplier?view