A five-axis machining center is a highly technological, high-precision machine tool specialized in processing complex surfaces, and has a crucial influence on industries such as national aerospace, military, scientific research, precision instruments, and high-precision medical devices.

The five axis CNC machine tool can control three linear coordinate axes and two rotation coordinate axes for simultaneous movement, allowing the cutting tool and workpiece to perform cutting operations according to a predetermined trajectory. Customized parts are often manufactured using 5-axis CNC machining in industries such as aerospace, petrochemical engineering, medical equipment, military products, and automobile parts production.

The aerospace industry requires extremely high precision for aircraft, rockets, and satellites. Poorly manufactured parts on a flying machine may hinder its normal operation and lead to manufacturing defects that could cause a crash. Using five axis CNC machining tools can greatly increase the accuracy of these applications. Complexity is the main reason why aerospace companies rely so heavily on five axis CNC. Aircraft components usually have complex geometric shapes - often including curves and internal cuts - that take a long time to process on 3-axis settings.

Oil and gas components on drilling platforms and refineries usually require customized designs and specialized machining to create them. Since these parts cannot be purchased in stores, many petrochemical companies use five axis CNC machining to produce their own parts.

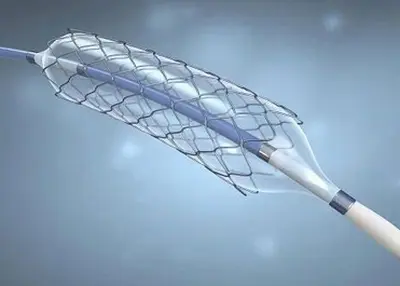

Medical components and tools require precise designs to ensure that the components used for surgery or replacement fit perfectly. Improper cutting or imperfect edges can render medical supplies unusable. This makes 5-axis machining the preferred method for creating customized medical tools and components. Titanium and stainless steel surgical knives are often manufactured using five axis CNC services. These parts must be manufactured with high precision and are often mass-produced, which is advantageous for increasing the efficiency of five axis CNC machines.

Modern automobiles are equal parts electronic and mechanical marvels. Five-axis machines can be used to ensure the correct fit of mechanical parts. In addition, smaller electrical enclosures and other components may require higher-axis CNC machines for processing. New energy vehicles are indeed a trend, and the heat dissipation substrate is made of aluminum-silicon material, which greatly improves the performance of power modules. Tested, it can produce 5 times the product life. It can also be designed into different shapes such as needles and arcs to meet customer needs. Some manufacturers can also provide surface treatments such as sandblasting, anodizing, and electroplating.

As a professional CNC China company, Richconn provides quality affordable 5-axis CNC solutions for customers all over the world. Feel free to contact us at any time!

What Is Titanium? (Definition and Guide)February 26, 2024How to choose titanium for your project? Familiarize yourself with the various titanium grades and learn how to choose the most suitable grade for your needs.view

What Is Titanium? (Definition and Guide)February 26, 2024How to choose titanium for your project? Familiarize yourself with the various titanium grades and learn how to choose the most suitable grade for your needs.view Ultra-High Precision Laser Cutting Technology: A Detailed Explanation of Its Technology and ApplicationsJanuary 3, 2024We delve into the intricacies of ultra-high-precision laser cutting, exploring its technology, applications, benefits and challenges.view

Ultra-High Precision Laser Cutting Technology: A Detailed Explanation of Its Technology and ApplicationsJanuary 3, 2024We delve into the intricacies of ultra-high-precision laser cutting, exploring its technology, applications, benefits and challenges.view Exploring Chameleon PVD Coating in DesignJanuary 5, 2024The world of design is constantly evolving, with new techniques and materials pushing boundaries and inspiring creativity. One such innovation that has revolutionized the design industry is Chameleon ...view

Exploring Chameleon PVD Coating in DesignJanuary 5, 2024The world of design is constantly evolving, with new techniques and materials pushing boundaries and inspiring creativity. One such innovation that has revolutionized the design industry is Chameleon ...view Powder Coating 101: What Is Powder Coating?August 14, 2023When seeking effective and durable finishing solutions for metal components, one term often comes up: "powder coating". The world of powder coating is full of mysteries. Whether you're c...view

Powder Coating 101: What Is Powder Coating?August 14, 2023When seeking effective and durable finishing solutions for metal components, one term often comes up: "powder coating". The world of powder coating is full of mysteries. Whether you're c...view The Working Principle of CNC Cutting Aluminum SheetsFebruary 29, 2024The Intricacies of CNC Cutting Aluminum SheetsIn the intricate world of manufacturing and fabrication, CNC cutting aluminum sheets has become a cornerstone practice, heralding a new era of precision a...view

The Working Principle of CNC Cutting Aluminum SheetsFebruary 29, 2024The Intricacies of CNC Cutting Aluminum SheetsIn the intricate world of manufacturing and fabrication, CNC cutting aluminum sheets has become a cornerstone practice, heralding a new era of precision a...view How Much is a CNC Machine?September 21, 2023The cost of a CNC (Computer Numerical Control) machine can vary widely depending on several factors, including the type of machine, its size, capabilities, brand, and whether it's new or used.view

How Much is a CNC Machine?September 21, 2023The cost of a CNC (Computer Numerical Control) machine can vary widely depending on several factors, including the type of machine, its size, capabilities, brand, and whether it's new or used.view

EN

EN

ru

ru