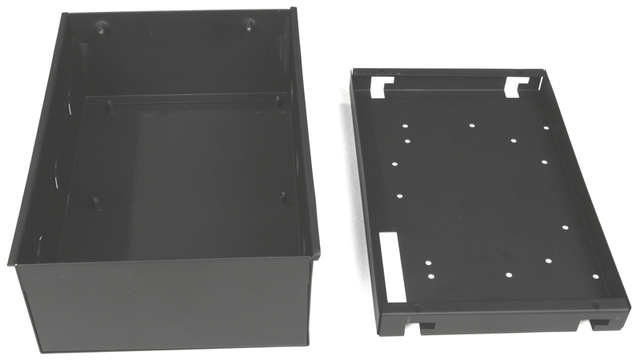

Surface finishing is to clean, sweep, deburr, de-grease, de-oxidize, etc., the surface of the workpiece, which is used to meet the corrosion resistance, abrasion resistance, decorative or other special functional requirements of the product. The surface finishing of metal castings are mainly mechanical polishing, chemical treatment, heat treatment, spraying and so on.

The appearance of the processed workpiece is inseparable from the design, color, material and process, of which the surface finishing process is the most direct reflection of the product appearance. surface finishing can enhance the product appearance, texture, function and other aspects of performance. Manufacturing and processing industry commonly used surface finishing methods are: plating, baking paint, silk screen, surface drawing, sandblasting, oxidation, polishing, laser engraving and so on.

Plating through a chemical reaction, attached to the surface of the material a layer of other metals, used to increase the corrosion resistance of the metal, and can achieve a certain role in beautifying the appearance of a commonly used surface treatment, such as: zinc plating, nickel plating and so on.

Spraying is the most common surface finishing, whether plastic or hardware are applicable. Spraying generally includes spraying oil, spraying powder, etc., the most common is spraying oil. The paint used for spraying is commonly known as paint, which is composed of resin, pigment, solvent, and other additives. Plastic spraying generally has two coats of paint, the surface showing color is called the top coat, and the most surface transparent layer is called the protective paint.

Through spraying, high temperature baking, etc., a layer of various colors of paint on the surface of the material, used to beautify the appearance, and can increase the corrosion resistance of the material. Generally there are two kinds of liquid baking paint and powder baking paint, of which powder baking paint is the most common. Baking paint surface is not conductive. There are EMC requirements of the area does not allow baking paint (baking paint products are generally reserved for spraying margin ...).

A process in which patterns are printed on the surface of plastic parts through pad printing, screen printing and transfer printing methods.

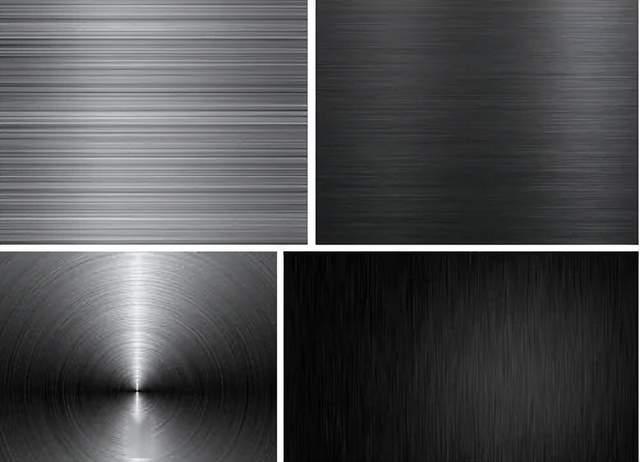

The material will be placed between the upper and lower rollers of the wire drawing machine, the rollers are attached to the abrasive belt, driven by the motor, so that the material through the upper and lower abrasive belts, pulling out a trace on the surface of the material, according to the different abrasive belts, the trace thickness is not the same, the main role is to beautify the appearance. Generally it is the aluminum material that is considered to use the brushed surface finishing.

Through the sand blasting machine's wind will sand particles to the surface of the workpiece, in the surface of the workpiece to form a layer of dense pits, the main role is to remove the dirt on the surface of the workpiece, increase the adhesion of the surface of the workpiece, for the subsequent surface finishing way to prepare.

Oxidize the metal on the surface of the workpiece to form a dense protective film on the surface of the workpiece to increase the corrosion resistance of the workpiece. Generally there are two ways of conductive oxidation and anodic oxidation, is a commonly used surface finishing, such as radiator surface anodic oxidation (can have different colors).

Polishing refers to the use of mechanical, chemical or electrochemical effects, so that the surface roughness of the workpiece is reduced to obtain a bright, flat surface processing methods, is the use of polishing tools and abrasive particles or other polishing media on the surface of the workpiece to carry out the modification of processing. Polishing can not improve the dimensional accuracy or geometric precision of the workpiece, but to get a smooth surface or mirror luster for the purpose, and sometimes also used to eliminate the luster (matte).

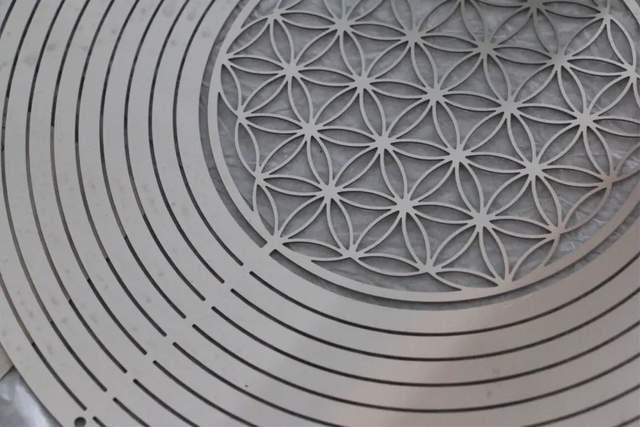

Also called laser engraving or laser marking, it is a process of surface finishing using optical principles. It utilizes a high-intensity focused laser beam emitted by a laser at a focal point to oxidize the material and thus process it.

Usually referred to as etching, also known as photochemical etching, refers to the exposure of the plate, after developing, to be etched in the area of the removal of the protective film, in contact with the etching of chemical solutions to achieve the role of dissolution and corrosion, the formation of concave-convex or hollow molding effect.

Richconn offers exceptional CNC surface finishing services to enhance your products. We combine leading-edge CNC technology with cutting-edge surface finishing methods to ensure that your parts and products meet the highest standards of appearance and performance.

Our CNC surface preparation services include, but are not limited to, the following:

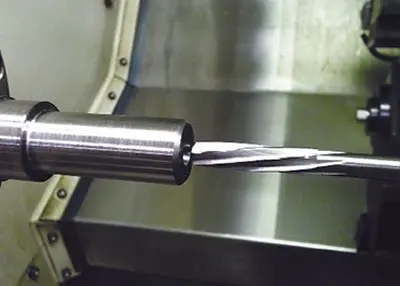

Precision Grinding: CNC-controlled precision grinding ensures the accuracy and surface smoothness of your parts.

Metal plating: We provide a variety of metal plating options, such as chrome, nickel, zinc, etc., to enhance the corrosion and abrasion resistance of the products.

Painting and sandblasting: We use high-quality paints and granules to realize beautiful and durable surface coating effect.

Polishing and sanding: bring mirror shine to the products and improve the appearance quality.

Anti-corrosion coating: protects the product from environmental aggressions and prolongs its service life.

Our team of professionals will carefully design and execute a surface preparation program tailored to your needs to ensure the best possible results.Richconn is committed to providing high-quality, reliable CNC surface preparation services, no matter the size of your project. Contact us and let's work together to enhance the quality and value of your products.

Welding vs. Riveting: Differences, Advantages and DisadvantagesNovember 28, 2023Metal joining is a process of attaching or combining two or more metal pieces or parts together. Metal joining is essential for various industries, such as construction, automotive, aerospace, and manufacturing.view

Welding vs. Riveting: Differences, Advantages and DisadvantagesNovember 28, 2023Metal joining is a process of attaching or combining two or more metal pieces or parts together. Metal joining is essential for various industries, such as construction, automotive, aerospace, and manufacturing.view What is a CNC Machine?October 20, 2023The full name of CNC is Computer Numerical Control, and a tooling machine with a computer as the control center is called a CNC machine. The traditional tooling machines need to be manually operated to achieve a variety of metal processing techniques, CNC machine is by the engineers of the computer input product drawings, complete the product required tooling sequence, processing environment parameters and other data, by the computer according to the above instructions for automated production.view

What is a CNC Machine?October 20, 2023The full name of CNC is Computer Numerical Control, and a tooling machine with a computer as the control center is called a CNC machine. The traditional tooling machines need to be manually operated to achieve a variety of metal processing techniques, CNC machine is by the engineers of the computer input product drawings, complete the product required tooling sequence, processing environment parameters and other data, by the computer according to the above instructions for automated production.view Turning Cylindrical PartsOctober 16, 2023In the past, everything was simple: round parts were turned on lathes, while non-round parts were machined on mills. With the advent of CNC machining centers that effortlessly insert round part features, the dividing line between the two machining processes became blurred.view

Turning Cylindrical PartsOctober 16, 2023In the past, everything was simple: round parts were turned on lathes, while non-round parts were machined on mills. With the advent of CNC machining centers that effortlessly insert round part features, the dividing line between the two machining processes became blurred.view The Difference Between Precision Sheet Metal Fabrication and Ordinary Sheet Metal FabricationSeptember 27, 2023In recent years, as the market demand for precision of sheet metal parts has increased, precision sheet metal fabrication has also begun to enter the center stage of the sheet metal industry.view

The Difference Between Precision Sheet Metal Fabrication and Ordinary Sheet Metal FabricationSeptember 27, 2023In recent years, as the market demand for precision of sheet metal parts has increased, precision sheet metal fabrication has also begun to enter the center stage of the sheet metal industry.view Fasteners 101: Common Types of Automotive FastenersAugust 24, 2023Automotive fasteners are an essential component in the construction and maintenance of vehicles. As a result, automotive part manufacturing relies on high-tolerance designs that include connecting mec...view

Fasteners 101: Common Types of Automotive FastenersAugust 24, 2023Automotive fasteners are an essential component in the construction and maintenance of vehicles. As a result, automotive part manufacturing relies on high-tolerance designs that include connecting mec...view What Are the High Temperature and Corrosion Resistant High Hardness Alloy Wear Resistant Metal Materials?October 30, 2023Corrosion-resistant metals are used in a wide range of applications, from the culinary industry to aerospace applications. Like most metals, they provide structural strength and heat resistance, but the metals listed in this article are also more resistant to corrosion than others.view

What Are the High Temperature and Corrosion Resistant High Hardness Alloy Wear Resistant Metal Materials?October 30, 2023Corrosion-resistant metals are used in a wide range of applications, from the culinary industry to aerospace applications. Like most metals, they provide structural strength and heat resistance, but the metals listed in this article are also more resistant to corrosion than others.view

EN

EN

ru

ru