Rev up your expectations as we delve into the intricate world of CNC machined motorcycle parts. I'm excited to guide you through the details, showcasing how Richconn is your go-to source for precision solutions. Let's ride into the comprehensive exploration!

Welcome to the core of CNC machining. In this section, we will unravel the intricate workings of CNC machining, providing you with a detailed understanding of the fundamental principles behind this precision process.

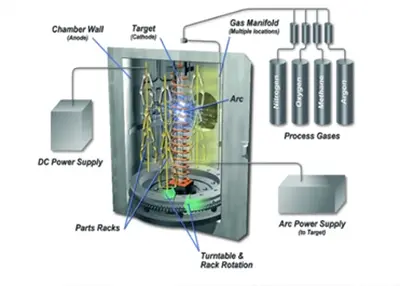

CNC machining operates on the principles of computer numerical control, where machine tools are directed and controlled by computerized systems. These systems interpret design specifications and translate them into precise movements of cutting tools, resulting in highly accurate and repeatable manufacturing processes.

Richconn employs state-of-the-art CNC machines, ensuring optimal precision in every step of the machining operation. Our commitment to technological advancement guarantees that your motorcycle parts are crafted with the utmost accuracy.

Delve into the heart of our CNC machining process by exploring the critical aspects of materials selection and the workflow involved. We meticulously choose materials that meet the highest standards for durability, strength, and performance.

The process workflow, from design to final production, is a well-choreographed dance of technology and craftsmanship. Richconn's engineers and technicians work seamlessly to transform raw materials into precision-crafted motorcycle components.

In this section, we'll conduct a detailed analysis, highlighting the advantages that set CNC machining apart from traditional methods. Let's explore the intricacies that make CNC machining the preferred choice for crafting motorcycle parts.

CNC machining excels in precision, allowing for intricate designs and tight tolerances. The efficiency of CNC machines ensures swift production without compromising on quality. The flexibility inherent in CNC machining empowers Richconn to adapt to various design requirements and produce complex shapes with ease.

Quality is paramount at Richconn. We implement stringent quality assurance measures to guarantee that each CNC machined motorcycle part meets the specified standards. The correlation between quality and precision is a cornerstone of our manufacturing process. Every component undergoes meticulous inspection to ensure it aligns with our commitment to excellence.

Now, let's delve into the world of customization, where Richconn's expertise shines in custom CNC machined parts to meet the unique requirements of your motorcycle model.

At Richconn, we understand that each motorcycle model is distinct. Our CNC machining process is finely tuned to accommodate the specific design nuances of various models. From sportbikes to cruisers, we take pride in adapting our machining techniques to ensure seamless integration and optimal performance.

Our customer-centric approach sets us apart. We don't just manufacture parts; we collaborate with our clients to understand their preferences and specific needs. This collaborative spirit allows us to produce CNC machined parts that not only meet technical specifications but also align with the individual style and identity of your motorcycle.

Richconn's commitment to customer satisfaction is reflected in our ability to deliver tailor-made solutions. Whether it's a subtle modification or a comprehensive design overhaul, our CNC machining process is versatile enough to bring your vision to life.

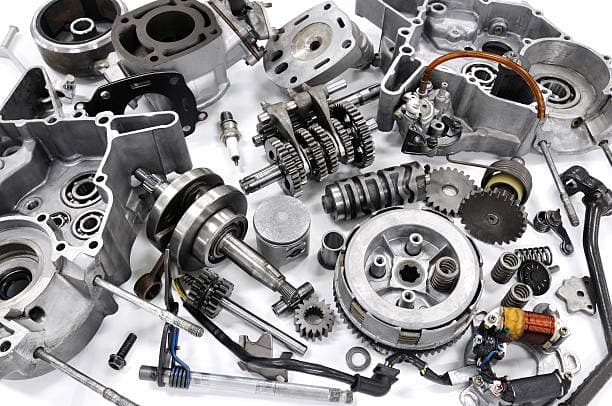

Let's shift our focus to the diverse world of CNC machined motorcycle components. In this section, we'll break down the intricacies of crafting specific parts such as brake system components, suspension parts, and engine components.

Brake systems demand the highest precision for optimal performance and rider safety. Richconn's CNC machining process ensures that each brake component is crafted with meticulous attention to detail. From brake discs to calipers, discover how our precision machining enhances the braking efficiency of your motorcycle.

Table: Brake System Component Specifications

| Component | Material | Precision Level | Application |

|---|---|---|---|

| Brake Discs | High-grade steel | ±0.02mm | Enhanced heat dissipation |

| Brake Calipers | Aluminum alloy | ±0.01mm | Optimal clamping force |

Suspension components play a crucial role in ride comfort and handling. Richconn's CNC machining ensures that each suspension part meets the highest standards, contributing to a smooth and controlled ride.

Table: Suspension Component Specifications

| Component | Material | Precision Level | Application |

|---|---|---|---|

| Shock Absorbers | Titanium alloy | ±0.005mm | Improved damping control |

| Fork Tubes | Aircraft aluminum | ±0.01mm | Enhanced stability |

The heart of any motorcycle lies in its engine. Richconn's CNC machining extends to engine components, ensuring that each part contributes to the overall performance and reliability of your motorcycle.

Table: Engine Component Specifications

| Component | Material | Precision Level | Application |

|---|---|---|---|

| Pistons | Forged aluminum | ±0.005mm | Optimal combustion |

| Cylinder Heads | Stainless steel | ±0.01mm | Improved heat dissipation |

Delve into the technological prowess that sets Richconn apart in the realm of CNC machining. This section explores the advanced equipment, quality control measures, and the commitment to precision that defines our CNC machining advantages.

Richconn's commitment to excellence begins with our investment in cutting-edge CNC machining equipment. Our machines, equipped with the latest technology, ensure optimal precision and efficiency in crafting motorcycle components. The integration of advanced features allows us to push the boundaries of what's possible in CNC machining.

Quality is not just a goal at Richconn; it's ingrained in our process. Rigorous quality control measures are implemented at every stage of CNC machining. Our inspection processes leave no room for compromise, guaranteeing that each component meets the highest standards before it reaches your motorcycle.

Table: Quality Control Parameters

| Quality Parameter | Inspection Method | Tolerance Level |

|---|---|---|

| Dimensional Accuracy | 3D Coordinate Measuring | ±0.01mm |

| Surface Finish | Optical Profilometer | Ra 0.1μm |

| Material Composition | Spectroscopy Analysis | ±0.5% |

Explore the foundations of Richconn as we provide insights into our company's background, history, and the extensive product range that positions us as a leading manufacturer and supplier in the CNC machining industry.

Established with a vision for precision, Richconn has evolved into a cornerstone in CNC machining. Founded in 2012, our journey has been marked by a relentless pursuit of excellence. Our state-of-the-art facilities and a dedicated team of experts position us as a reliable partner for your CNC machined motorcycle part needs.

Richconn's product range is as diverse as the world of motorcycles. From brake system components to engine parts, we offer a comprehensive selection. What sets us apart is our commitment to customization. Clients can choose from a range of options to tailor components to their specific requirements, ensuring a perfect fit for every motorcycle model.

Table: Richconn's Product Range

| Category | Key Products |

|---|---|

| Brake System Components | Brake Discs, Brake Calipers, Pads |

| Suspension Parts | Shock Absorbers, Fork Tubes |

| Engine Components | Pistons, Cylinder Heads, Camshafts |

Ensuring the longevity and optimal performance of CNC machined motorcycle parts requires proactive maintenance. In this section, we provide valuable insights into maintaining and caring for these precision components.

Preserving the quality and functionality of CNC machined parts involves adherence to specific maintenance practices. Regularly inspect components for signs of wear, and follow these guidelines for optimal performance:

Brake System Components:

Inspect brake pads and discs for wear regularly.

Check calipers for proper alignment and functionality.

Suspension Parts:

Ensure shock absorbers and fork tubes are free from leaks.

Lubricate moving parts according to the manufacturer's recommendations.

Engine Components:

Monitor piston rings and cylinder heads for any irregularities.

Follow the manufacturer's guidelines for oil changes and maintenance intervals.

Addressing common concerns ensures motorcycle enthusiasts are well-informed about the intricacies of maintaining CNC machined parts. Here are some frequently asked questions with expert answers:

Q: How often should brake pads be replaced?

A: Brake pad replacement frequency depends on usage and riding conditions. Regular inspection is recommended, and pads should be replaced if the thickness is near the manufacturer's specified limit.

Q: What is the lifespan of CNC machined pistons?

A: The lifespan of CNC machined pistons is influenced by factors such as riding conditions and maintenance. Regularly inspecting piston rings and following recommended maintenance practices can extend their lifespan.

As we conclude this journey through the intricate world of CNC machined motorcycle parts, it's evident that precision craftsmanship is not just a process at Richconn; it's a commitment to excellence. Our CNC machining advantages, customization options, and extensive product range make us a trusted partner for motorcycle enthusiasts seeking unparalleled quality.

Embrace the precision wave with Richconn, where every component is meticulously crafted to elevate your ride. Whether it's conquering the curves with confidence or enjoying the smooth performance of your engine, our CNC machined parts are designed to exceed expectations.

Explore our product range, experience the advantages of precision machining, and ride with the assurance that comes from knowing your motorcycle is equipped with the finest CNC machined parts. The road to excellence begins with Richconn – your destination for precision, quality, and the perfect ride.

Differences Between Chrome, Galvanized and Nickel PlatingOctober 20, 2023The electroplating process is widely used in industrial design to provide a variety of functional and aesthetic properties by forming a fine layer of different metals or alloys on the surface of an object. This process is usually carried out using the principle of electrolysis, which helps in preventing oxidation of the metal and improves abrasion resistance, light reflection, electrical conductivity, corrosion resistance, and other important properties.view

Differences Between Chrome, Galvanized and Nickel PlatingOctober 20, 2023The electroplating process is widely used in industrial design to provide a variety of functional and aesthetic properties by forming a fine layer of different metals or alloys on the surface of an object. This process is usually carried out using the principle of electrolysis, which helps in preventing oxidation of the metal and improves abrasion resistance, light reflection, electrical conductivity, corrosion resistance, and other important properties.view What Is Titanium Used for? (5 Common Uses)August 29, 2023Titanium has carved an impressive niche for itself within a myriad of industries and applications, all thanks to its extraordinary and unparalleled properties. The element of Titanium is symbolized by...view

What Is Titanium Used for? (5 Common Uses)August 29, 2023Titanium has carved an impressive niche for itself within a myriad of industries and applications, all thanks to its extraordinary and unparalleled properties. The element of Titanium is symbolized by...view Semiconductor Chip Carrier Manufacturing: Introduction from Materials to Finished ProductsAugust 14, 2023With the development of science and technology, semiconductor chips are being widely used in various fields. High quality chip carriers are crucial to ensure the performance of chips during semiconduc...view

Semiconductor Chip Carrier Manufacturing: Introduction from Materials to Finished ProductsAugust 14, 2023With the development of science and technology, semiconductor chips are being widely used in various fields. High quality chip carriers are crucial to ensure the performance of chips during semiconduc...view Inconel 718: A Superalloy with Lasting RelevanceOctober 12, 2023Metal 3D printing has finally catapulted Inconel, the classic nickel-based heat-resistant alloy, into the 21st century. Inconel 718, the hardened version of Inconel 625, is the latest addition to our growing range of metals for Direct Metal Laser Sintering (DMLS).view

Inconel 718: A Superalloy with Lasting RelevanceOctober 12, 2023Metal 3D printing has finally catapulted Inconel, the classic nickel-based heat-resistant alloy, into the 21st century. Inconel 718, the hardened version of Inconel 625, is the latest addition to our growing range of metals for Direct Metal Laser Sintering (DMLS).view Some Knowledge You Need to Learn About Design for ManufacturingFebruary 22, 2024Design for Manufacturing (DFM) is a set of best practices that aim to minimize manufacturing errors by focusing on mitigating defects and assessing the quality and dependability of supply chains.view

Some Knowledge You Need to Learn About Design for ManufacturingFebruary 22, 2024Design for Manufacturing (DFM) is a set of best practices that aim to minimize manufacturing errors by focusing on mitigating defects and assessing the quality and dependability of supply chains.view Explain 5 Common Electroplating ProcessesOctober 24, 2022In mechanical design, electroplating is one of our most common surface treatment processes for parts. Today we will take a look at 5 commonly used electroplating processes. There are many methods of e...view

Explain 5 Common Electroplating ProcessesOctober 24, 2022In mechanical design, electroplating is one of our most common surface treatment processes for parts. Today we will take a look at 5 commonly used electroplating processes. There are many methods of e...view

EN

EN

ru

ru